Compound, liquid crystal composition, liquid crystal display element and liquid crystal display device

A technology for liquid crystal compositions and compounds, applied in liquid crystal materials, chemical instruments and methods, instruments, etc., to achieve the effects of high solubility, moderate dielectric anisotropy Δε, and high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

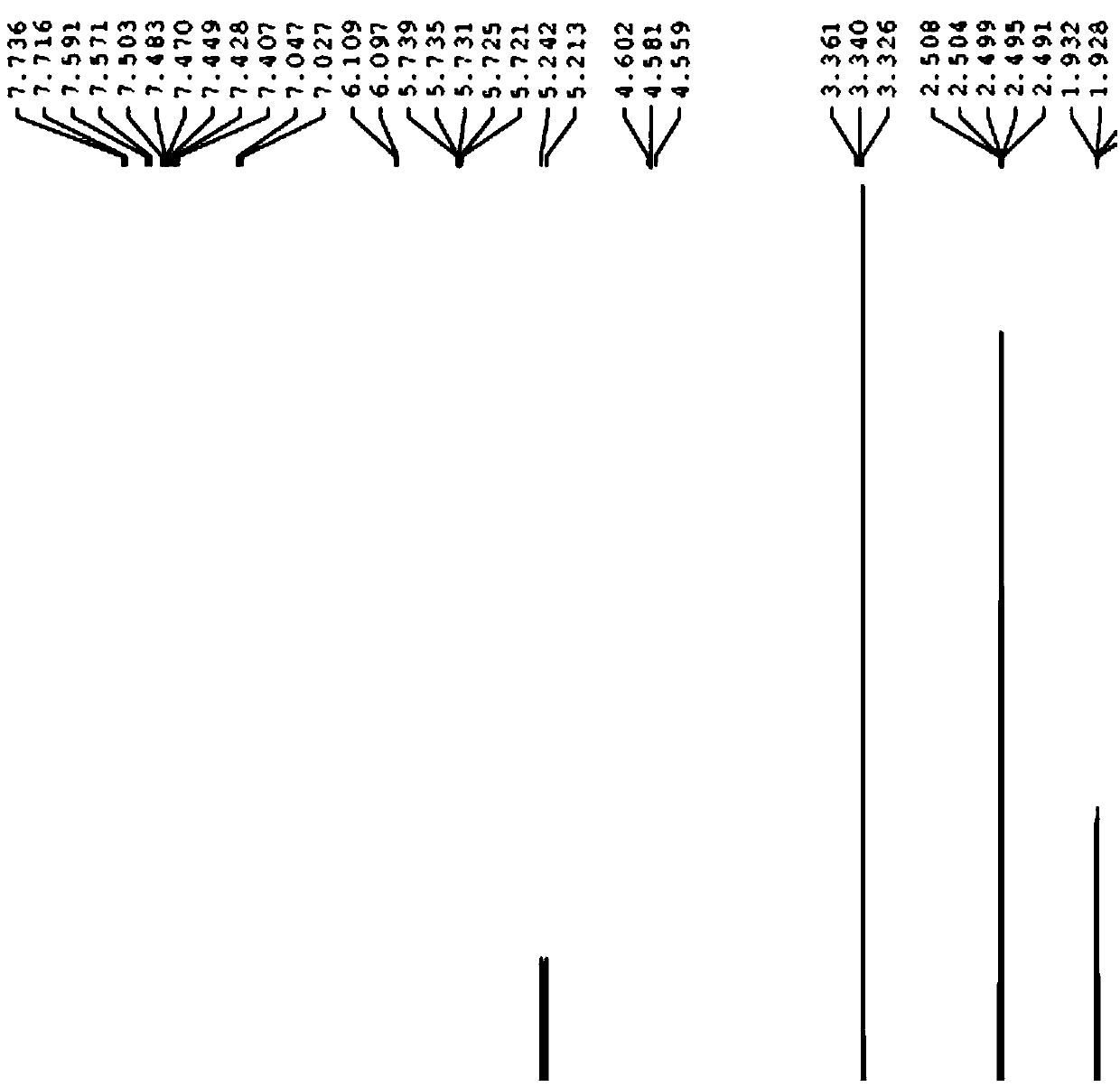

Image

Examples

preparation example Construction

[0112] As the preparation method of the liquid crystal display of the present invention, those skilled in the art can select an appropriate method for preparation according to common knowledge in the field. As an example of the preparation method of the liquid crystal display of the present invention, for example, the preparation method comprising the following steps:

[0113] Coating an alignment material evenly on the surface of the first substrate and the second substrate. The alignment material can be polyimide, and the evenly coated alignment material is heated and cured at a heating temperature of 210-250°C to form an alignment layer;

[0114] Scatter spacers on the surface of the second substrate, apply frame glue along the edge of the first substrate, and cure at 100°C to 150°C;

[0115] arranging the first substrate and the second substrate oppositely, and bonding them together to form a structure with a sandwich space;

[0116] The liquid crystal composition is inje...

Embodiment 1

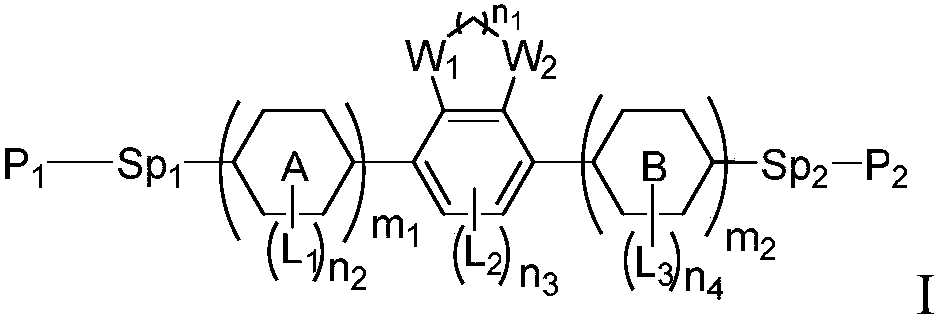

[0151] The compound structural formula is shown in the following formula I-1-3:

[0152]

[0153] Its preparation route is as follows:

[0154]

[0155] The specific operation process of preparation:

[0156] Intermediate 3

[0157] Put 0.1mol of intermediate 1, 0.1mol of intermediate 2, 0.12mol of anhydrous potassium carbonate, 0.5L of toluene, 0.1L of water into a 1L three-necked flask, add palladium carbon under nitrogen protection, and heat to reflux for 2 hours. The liquid was separated, the organic phase was washed with 0.2 L of water, the organic phase was passed through a 50 g silica gel column, 150 g of toluene was washed into the column, and spin-dried to obtain intermediate 3.

[0158] Intermediate 4

[0159] Put the aforementioned intermediate 3 into a 2L three-necked flask, 0.5L toluene, 0.1L absolute ethanol, 10g palladium carbon (5%), evacuate nitrogen 5 times, evacuate hydrogen 3 times, stir and hydrogenate for 3 hours, pour the system into Wash the c...

Embodiment 2

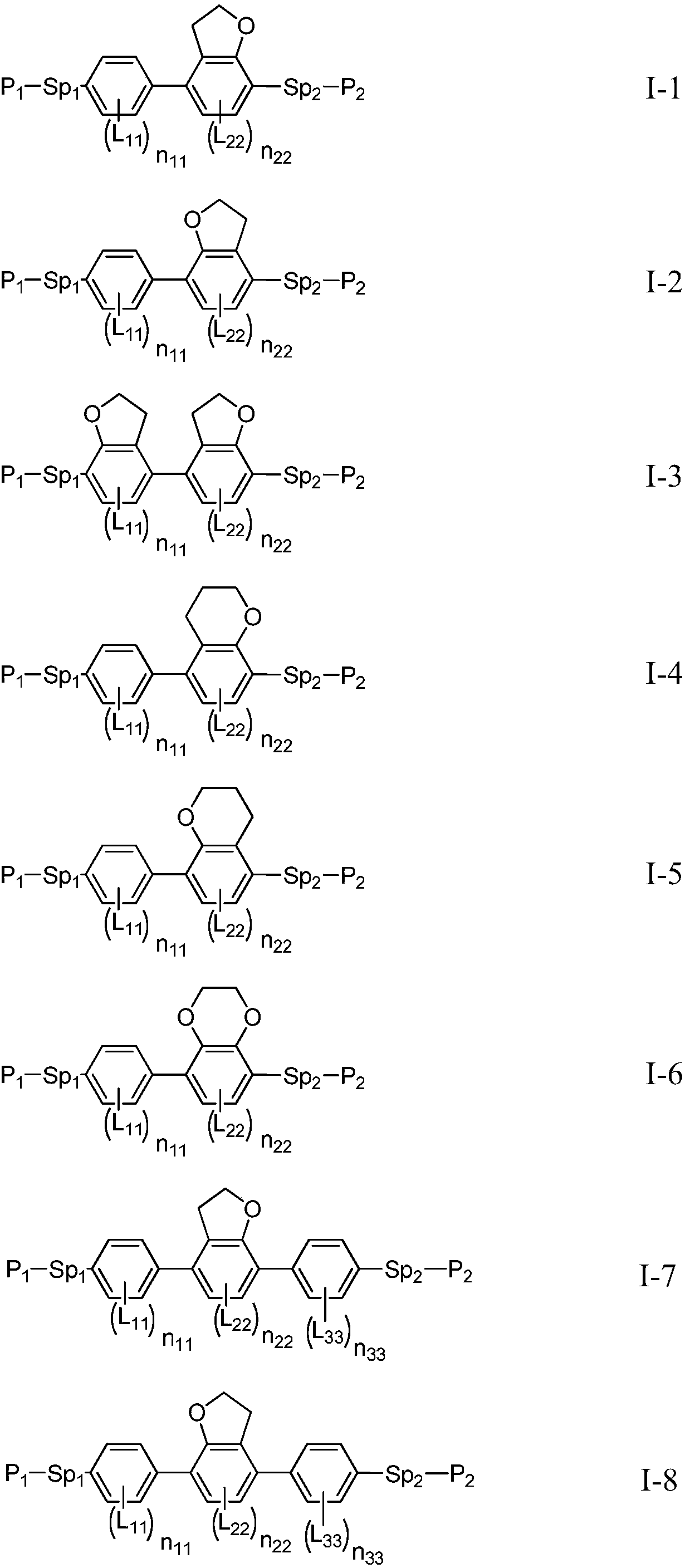

[0166] The compound structural formula is shown in the following formula I-1-17:

[0167]

[0168] Its preparation route is as follows:

[0169]

[0170] The specific operation process of preparation:

[0171] Intermediate 6

[0172] Put 0.1 mol of intermediate 5, 0.1 mol of intermediate 2, 0.12 mol of anhydrous potassium carbonate, 0.5 L of toluene, 0.1 L of water into a 1 L three-necked flask, add palladium carbon under nitrogen protection, and heat to reflux for 2 hours. The liquid was separated, the organic phase was washed with 0.2 L of water, the organic phase was passed through a 50 g silica gel column, 150 g of toluene was washed into the column, and spin-dried to obtain intermediate 6.

[0173] Intermediate 7

[0174] Put the aforementioned intermediate 6, 0.5L toluene, and 1.1mol formic acid into a 2L three-necked flask, reflux for 4 hours, separate the liquids, wash the organic phase with 10% sodium carbonate solution until neutral, dry it with anhydrous so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com