Environment-friendly absorbent for absorbing formaldehyde and preparation method thereof

A technology for adsorbing formaldehyde and absorbents, applied in the field of environmentally friendly absorbents, can solve the problems of long cycle, large influence of ambient temperature, single use, etc., and achieve excellent adsorption effect, good cushioning and shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

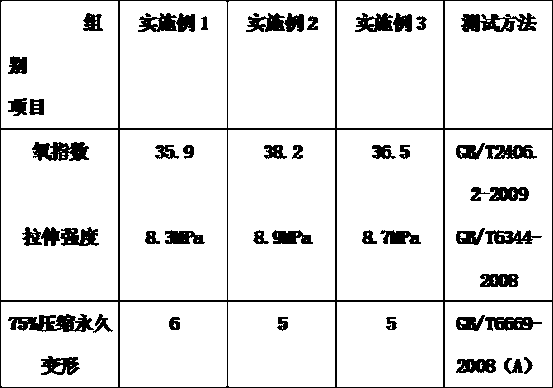

Embodiment 1

[0033] An environmentally friendly absorbent for absorbing formaldehyde, comprising the following raw materials in parts by weight: 28 parts of bamboo charcoal fiber, 33 parts of diatom powder, 15 parts of sepiolite fiber, 150 parts of vinyl acetate, 42 parts of polyethylene, 2 parts of imide, 1 part of azobisisobutyronitrile, 2 parts of 1,3-dimethyl-2-imidazolinone, 10 parts of silicone resin polyether emulsion, 15 parts of tert-butanol aqueous solution, α-alkenyl 3 parts of sodium sulfonate, 11 parts of fluoroalkyl polyether modified polysiloxane, 2 parts of nonylphenol polyoxyethylene ether, 10 parts of alum, 18 parts of sodium bicarbonate and 3 parts of gum arabic.

[0034] A preparation method for an environmentally friendly absorbent for adsorbing formaldehyde comprises the following steps:

[0035] 1) Pour 28 parts of bamboo charcoal fiber, 33 parts of diatom powder and 15 parts of sepiolite fiber into a blender for stirring treatment, and stir the materials evenly to p...

Embodiment 2

[0039] An environmentally friendly absorbent for absorbing formaldehyde, comprising the following raw materials in parts by weight: 40 parts of bamboo charcoal fiber, 36 parts of diatom powder, 20 parts of sepiolite fiber, 170 parts of vinyl acetate, 49 parts of polyethylene, 4 parts of imide, 3 parts of azobisisobutyronitrile, 3 parts of 1,3-dimethyl-2-imidazolinone, 12 parts of silicone resin polyether emulsion, 17 parts of tert-butanol aqueous solution, α-alkenyl 5 parts of sodium sulfonate, 14 parts of fluoroalkyl polyether modified polysiloxane, 4 parts of nonylphenol polyoxyethylene ether, 12 parts of alum, 21 parts of sodium bicarbonate and 6 parts of gum arabic.

[0040] A preparation method for an environmentally friendly absorbent for adsorbing formaldehyde, comprising the following steps:

[0041] 1) Pour 40 parts of bamboo charcoal fiber, 36 parts of diatom powder and 20 parts of sepiolite fiber into a blender for stirring treatment, and stir the materials evenly t...

Embodiment 3

[0045] An environmentally friendly absorbent for absorbing formaldehyde, comprising the following raw materials in parts by weight: 35 parts of bamboo charcoal fiber, 35 parts of diatom powder, 18 parts of sepiolite fiber, 168 parts of vinyl acetate, 46 parts of polyethylene, 3 parts of imide, 2 parts of azobisisobutyronitrile, 2 parts of 1,3-dimethyl-2-imidazolinone, 11 parts of silicone resin polyether emulsion, 16 parts of tert-butanol aqueous solution, α-alkenyl 4 parts of sodium sulfonate, 13 parts of fluoroalkyl polyether modified polysiloxane, 3 parts of nonylphenol polyoxyethylene ether, 11 parts of alum, 20 parts of sodium bicarbonate and 5 parts of gum arabic.

[0046] A preparation method for an environmentally friendly absorbent for adsorbing formaldehyde, comprising the following steps:

[0047] 1) Pour 35 parts of bamboo charcoal fiber, 35 parts of diatom powder and 18 parts of sepiolite fiber into a mixer for stirring, and stir the materials evenly to prepare a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com