Method for recovering and extracting SOD from conifer cherry residues

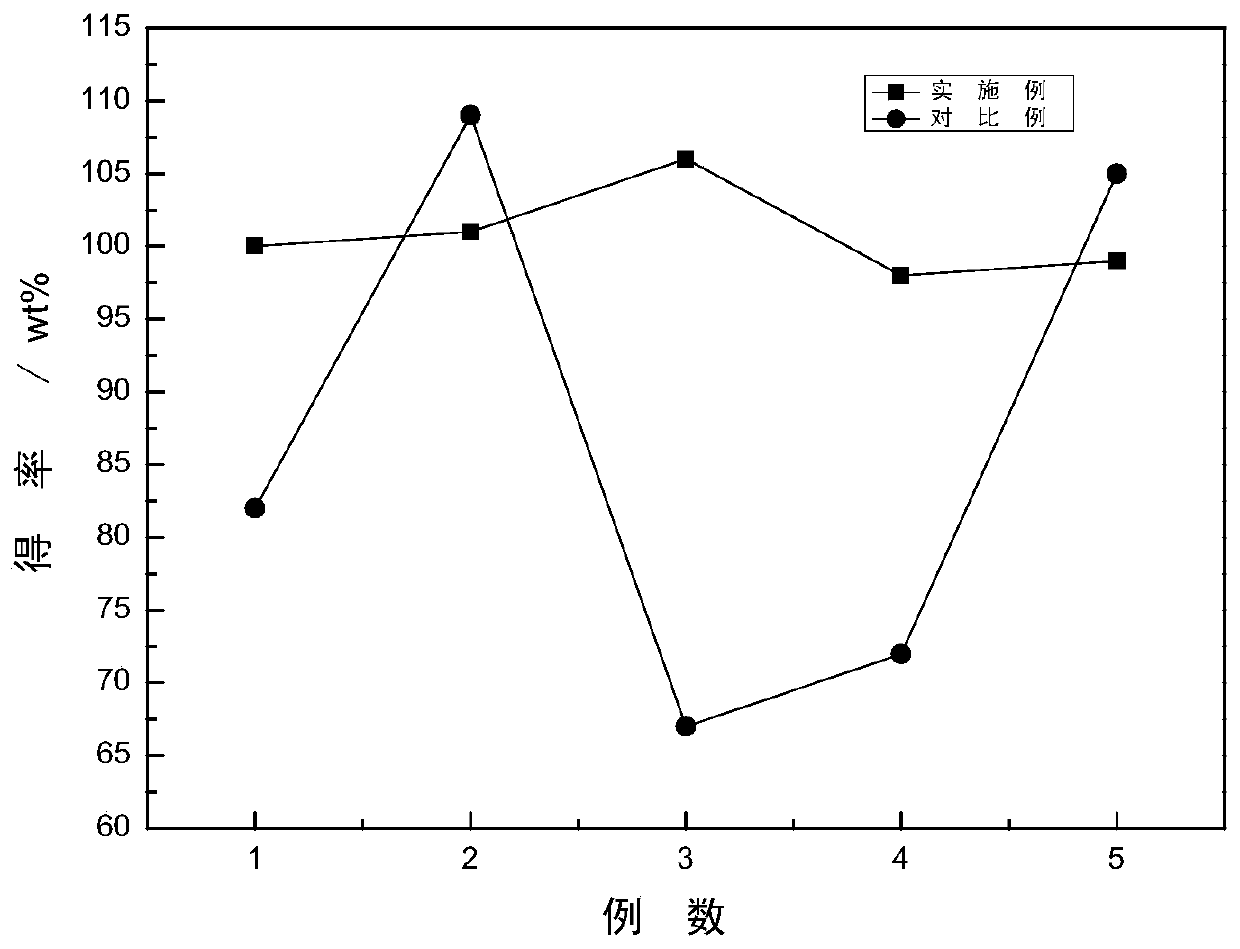

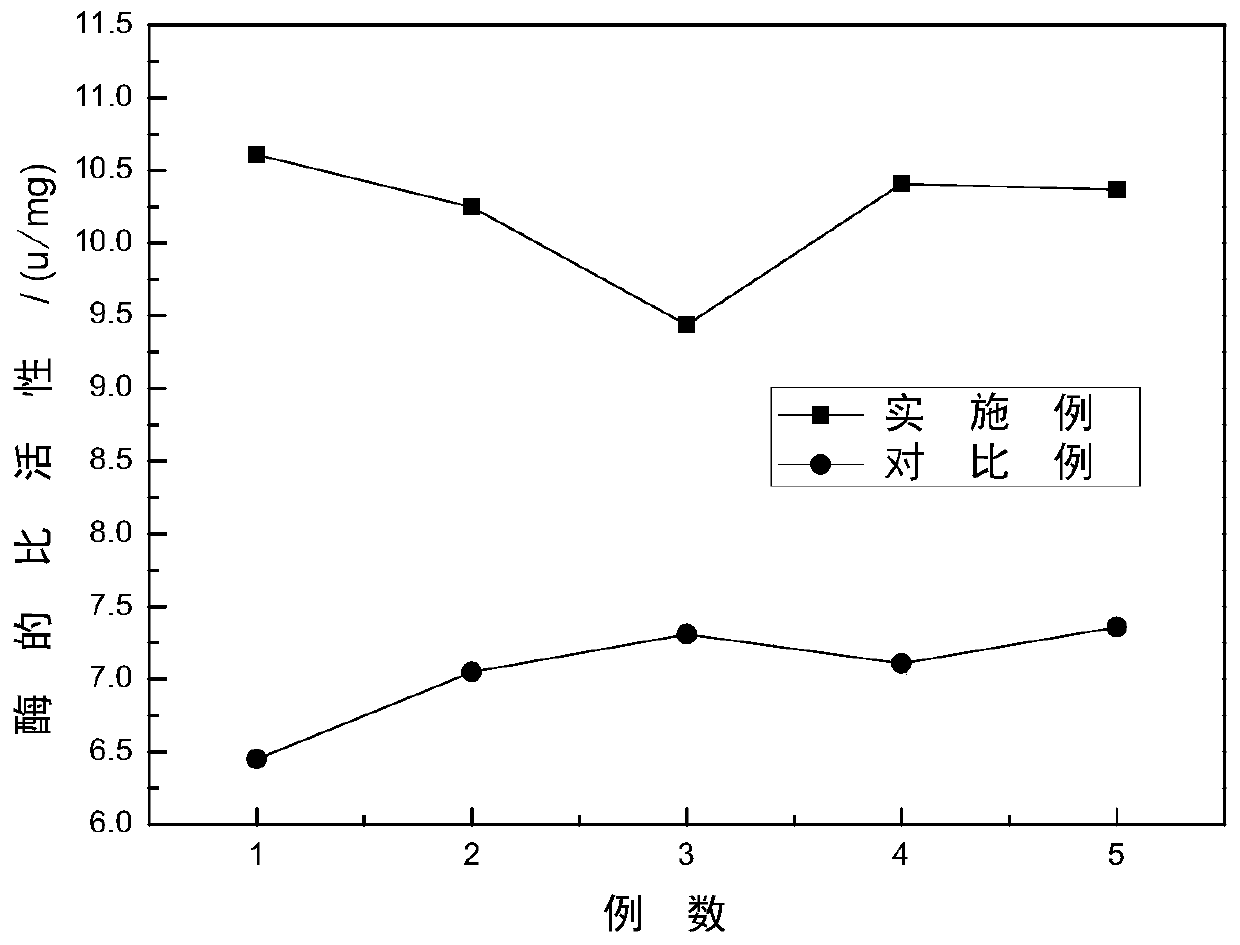

A technology of acerola and crude extract, applied in biochemical equipment and methods, enzymes, oxidoreductases, etc., can solve the problem of low utilization rate of acerola, ineffective utilization of acerola slag, waste of SOD, etc. problem, to achieve the effect of high specific activity, low equipment requirements, and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A kind of coniferous cherry pomace reclaims and extracts the method for SOD, and the steps are as follows:

[0072] S1. Take 1 kg of coniferous cherry residue as a raw material, carry out sub-sieving to remove impurities, clean the coniferous cherry residue and crush it with a beater into fragments of ≤ 2mm to obtain crushed powder;

[0073] S2. Add the crushed powder and cellulase described in step S1 to water twice the mass of the crushed powder at a mass ratio of 1g:600U, so that the water is completely submerged in the crushed powder, and the frequency is 20kHz, and the power is 100W. Ultrasonic crushing for 10 minutes, using a 160-mesh sieve to filter and remove the filter residue to obtain the filtrate;

[0074] S3. Use a filter membrane with a molecular weight cut-off of 50000Da to filter the filtrate described in step S2 to obtain a primary filtrate and a primary retentate, and then use a filter membrane with a molecular weight cut-off of 30000Da to filter the p...

Embodiment 2

[0081] A kind of coniferous cherry pomace reclaims and extracts the method for SOD, and the steps are as follows:

[0082] S1. Take 1 kg of coniferous cherry residue as a raw material, carry out sub-sieving to remove impurities, clean the coniferous cherry residue and crush it with a beater into fragments of ≤ 2mm to obtain crushed powder;

[0083] S2. Add the crushed powder and cellulase described in step S1 to water with a mass 3 times the mass of the crushed powder at a mass ratio of 1g:900U, so that the water is completely submerged in the crushed powder, and the frequency is 20kHz, and the power is 125W. Ultrasonic crushing for 14 minutes, using a 160-mesh sieve to filter and remove the filter residue to obtain the filtrate;

[0084] S3. Use a filter membrane with a molecular weight cut-off of 55000Da to filter the filtrate described in step S2 to obtain a primary filtrate and a primary retentate, and then use a filter membrane with a molecular weight cut-off of 20000Da t...

Embodiment 3

[0089] A kind of coniferous cherry pomace reclaims and extracts the method for SOD, and the steps are as follows:

[0090] S1. Take 1 kg of coniferous cherry residue as a raw material, carry out sub-sieving to remove impurities, clean the coniferous cherry residue and crush it with a beater into fragments of ≤ 2mm to obtain crushed powder;

[0091] S2. Add the crushed powder and cellulase described in step S1 to water twice the mass of the crushed powder at a mass ratio of 1g:700U, so that the water is completely submerged in the crushed powder, and the frequency is 10kHz, and the power is 50W. Ultrasonic crushing for 10 minutes, using a 160-mesh sieve to filter and remove the filter residue to obtain the filtrate;

[0092] S3. Use a filter membrane with a molecular weight cut-off of 50000Da to filter the filtrate described in step S2 to obtain a primary filtrate and a primary retentate, and then use a filter membrane with a molecular weight cut-off of 30000Da to filter the prim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com