Preparation method and application of Au-Hg-rGO nano composite material

A technology of nanocomposite materials and gold nanoparticles, applied in the direction of nanocarbon, material electrochemical variables, graphene, etc., can solve the problems of insufficient detection minimum concentration and limited detection range, and achieve high friendliness and high sensitivity , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1g of chloroauric acid powder was dissolved in a 100mL brown volumetric flask to obtain a chloroauric acid solution with a mass fraction of 1%, and a little citric acid-sodium citrate powder was weighed with an analytical balance to make a pH=5 buffer solution, and the chlorine Put 1mL of gold acid into 100mL of citric acid-sodium citrate buffer solution with a pH value of 5, stir and mix well, then quickly add 1mL of 10mg mL -1 Sodium borohydride (freshly prepared), then stirred for 4 hours to obtain gold nanoparticles. Then add the prepared gold nanoparticles into 100 μL of 1 mM mercury sulfate solution, stir for 30 minutes to obtain gold-mercury nanoparticles, put 10 mg of graphene oxide material into 10 mL of deionized water, and then sonicate for 1 hour to make the graphene The material is uniformly dispersed in deionized aqueous solution to obtain a suspension of graphene. Then take 10 mL of the above-mentioned gold-mercury nanoparticles and add them to the solut...

Embodiment 2

[0032] The Au-Hg / rGO nanocomposite material obtained in Example 1, acetic acid-sodium acetate, H 2 o 2 , TMB solution, the color changed from light brown to blue-green, proving that the nanocomposite can be used for H 2 o 2 detection.

[0033] Take 100 μL of the prepared Au-Hg / rGO nanoparticles and put them into a colorimetric tube, take out the acetic acid-sodium acetate with a pipette, prepare a buffer solution with pH=5, take 1.7 mL of it into the colorimetric tube, Slightly oscillate, let stand for a while, then add 100μL, 1mM TMB as a chromogenic substrate, then add 100μL, 1M H 2 o 2 , vibrate and shake well, and after 10 minutes of standing still, the color of the solution changes from light brown to blue-green, and its absorbance is measured.

Embodiment 3

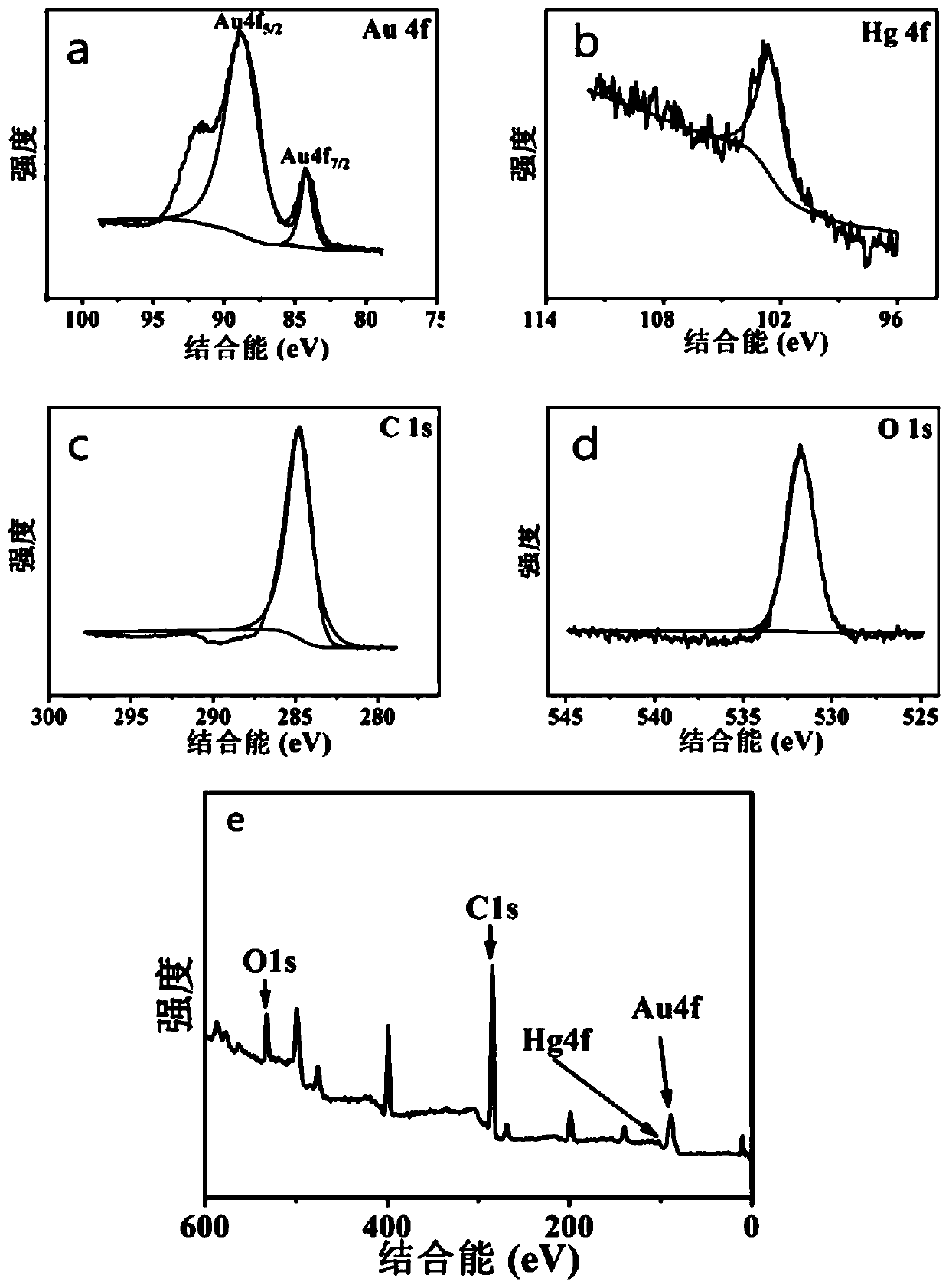

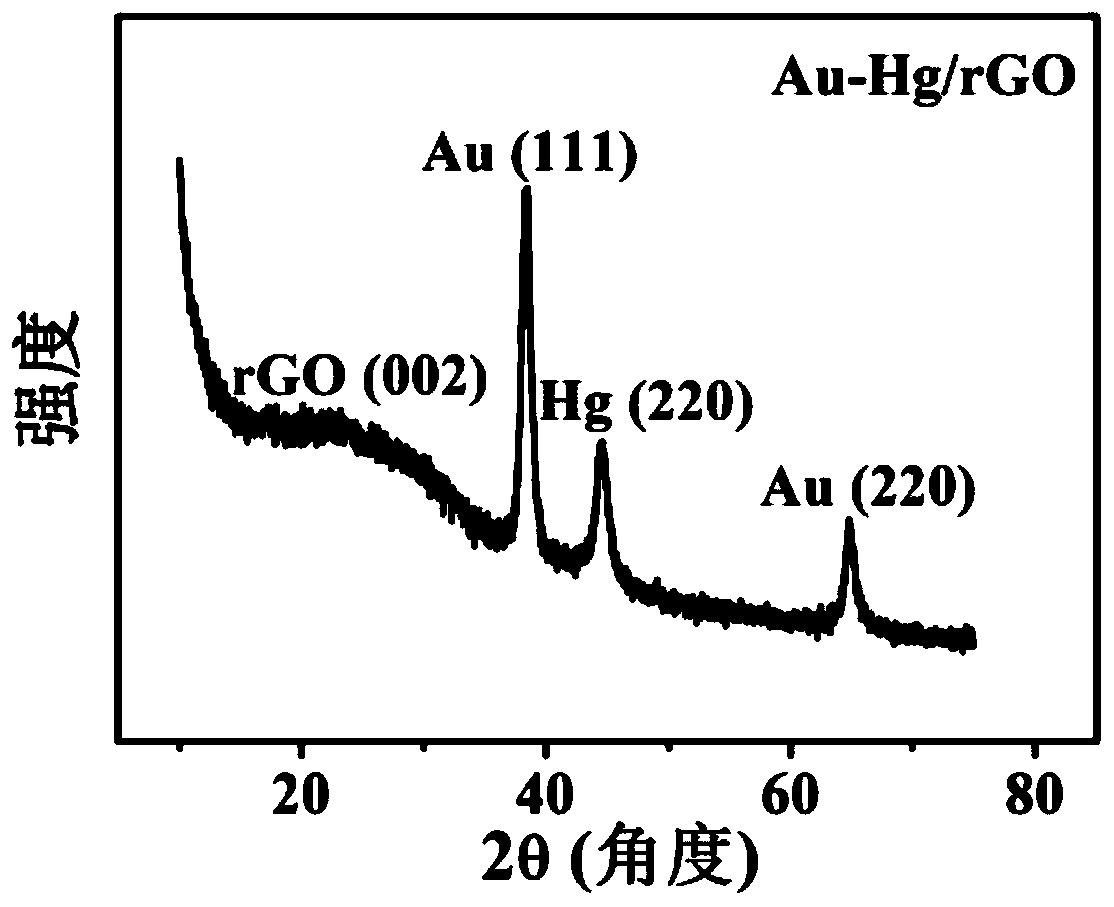

[0034] XPS characterization of embodiment 3 Au-Hg / rGO nanocomposite

[0035] XPS was used to determine the surface composition of nanocomposites such as figure 1 shown. Depend on figure 1 (a) It can be seen that the characteristic peak of gold appears at 80-90eV, which proves that we have successfully prepared gold nanoparticles. from figure 1 (b) It can be seen that there is a characteristic peak of mercury at about 102eV, showing that the material contains metallic mercury, figure 1 (c) is the XPS spectrum of C element. figure 1 (d) is the XPS spectrum of O element. figure 1 (e) is the total spectrum of Au, C, Hg, and O elements. It can be seen from the XPS test results that we have successfully prepared Au-Hg / rGO nanocomposites.

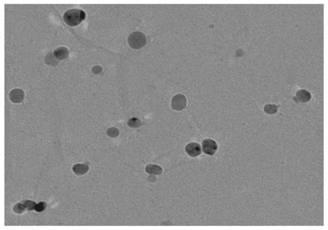

[0036] TEM characterization of Au-Hg / rGO nanocomposites, the results are as follows figure 2 shown.

[0037] This picture is a TEM picture scanned under the condition of 100nm scale, by figure 2 We can see that the Au-Hg nanocomposite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com