Solid self-microemulsion microcapsule containing astaxanthin and quercetin, preparation method and application thereof

A technology of self-microemulsion and quercetin, which is applied in the field of carrier systems in functional foods, can solve the problems of low bioavailability in vivo, poor water solubility of astaxanthin, and low stability of liquid self-microemulsion preparations, and achieve improved solubility And anti-oxidation, dissolution rate and bioavailability improvement, the effect of improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of the solid self-microemulsion microcapsule containing astaxanthin and quercetin of the present invention comprises the following steps:

[0060] (1) Preparation of blank self-microemulsion: Weigh 20-40 parts of oil phase, 50-100 parts of emulsifier and 30-60 parts of co-emulsifier, and mix thoroughly with electromagnetic stirring to obtain a transparent yellowish blank self-microemulsion ;

[0061] (2) Preparation of quercetin self-microemulsion: Weigh 100-250 parts of quercetin into the above-mentioned blank self-microemulsion, mix evenly under constant temperature magnetic stirring at 60°C, and obtain brown-yellow homogeneous quercetin Self-microemulsion;

[0062] (3) Preparation of astaxanthin-quercetin self-microemulsion: Weigh 1-5 parts of astaxanthin and add it into quercetin self-microemulsion, and stir magnetically at a constant temperature of 37°C to obtain a uniform orange-red oily liquid containing shrimp Self-microemulsion of penic...

Embodiment 1

[0076] The preparation method of the solid self-microemulsion microcapsule containing astaxanthin and quercetin of the present embodiment comprises the following steps:

[0077] (1), at 25°C, weigh 20 parts of castor oil (as oil phase), 20 parts of Tween 80 (as emulsifier), 30 parts of Cremophor RH 40 (as emulsifier) and 30 parts of PEG 400 (as emulsifier) co-emulsifier), at 60°C, with 400r / min electromagnetic stirring, uniformly and fully mixed for 30min, to obtain a light yellow, clear and uniform blank self-microemulsion.

[0078] (2) After weighing 10 parts of blank self-microemulsion, add 100 parts of quercetin several times in a small amount to the system, and mix evenly under constant temperature magnetic stirring at 60°C to obtain a yellow, clear, uniform, relatively viscous quercetin self-microemulsion milk.

[0079] (3) After cooling to room temperature, add 3 parts of astaxanthin into quercetin self-microemulsion, and under constant temperature magnetic stirring ...

Embodiment 2

[0083] The preparation method of the solid self-microemulsion microcapsule containing astaxanthin and quercetin of the present embodiment comprises the following steps:

[0084] (1), at 25°C, weigh 20 parts of castor oil (as oil phase), 20 parts of Tween 80 (as emulsifier), 30 parts of Cremophor RH 40 (as emulsifier) and 30 parts of Transcutol HP (as emulsifier) co-emulsifier), at 60°C, with 400r / min electromagnetic stirring, uniformly and fully mixed for 35min, to obtain a blank self-microemulsion with light yellow, clear and uniform, good fluidity.

[0085] (2) After weighing 10 parts of blank self-microemulsion, add 100 parts of quercetin several times in a small amount to the system, and uniformly mix under constant temperature magnetic stirring at 60° C. to obtain yellow and clear quercetin self-microemulsion.

[0086] (3) After cooling to room temperature, add 3 parts of astaxanthin into quercetin self-microemulsion, and under constant temperature magnetic stirring at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

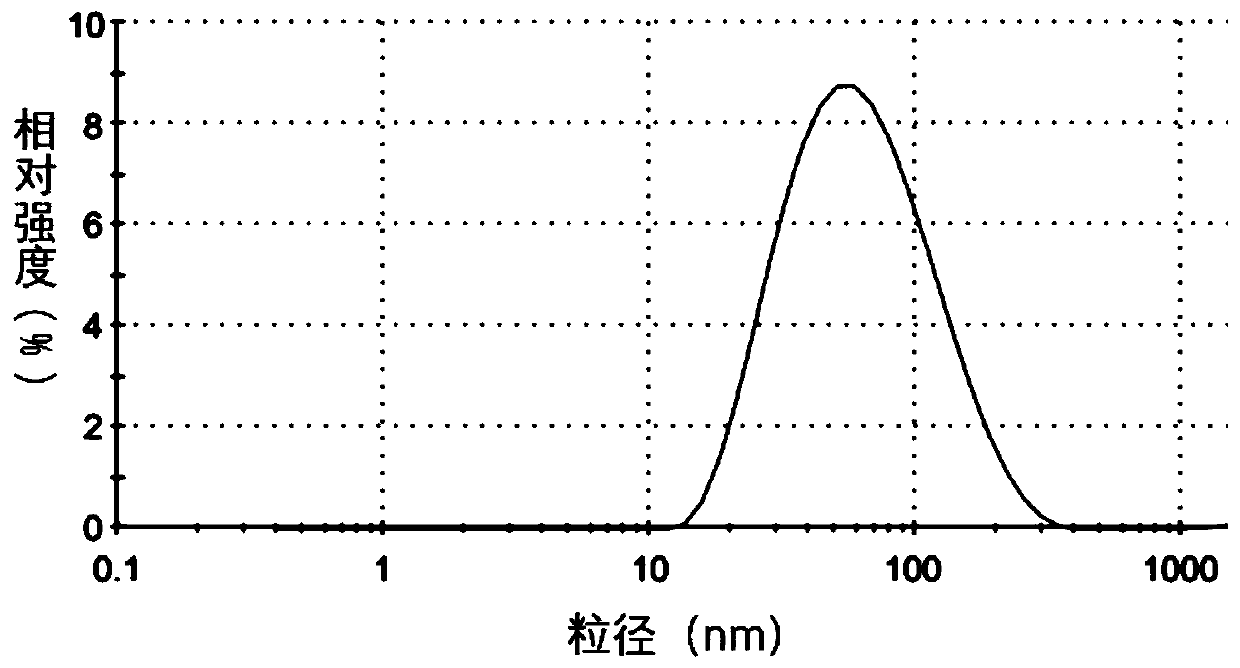

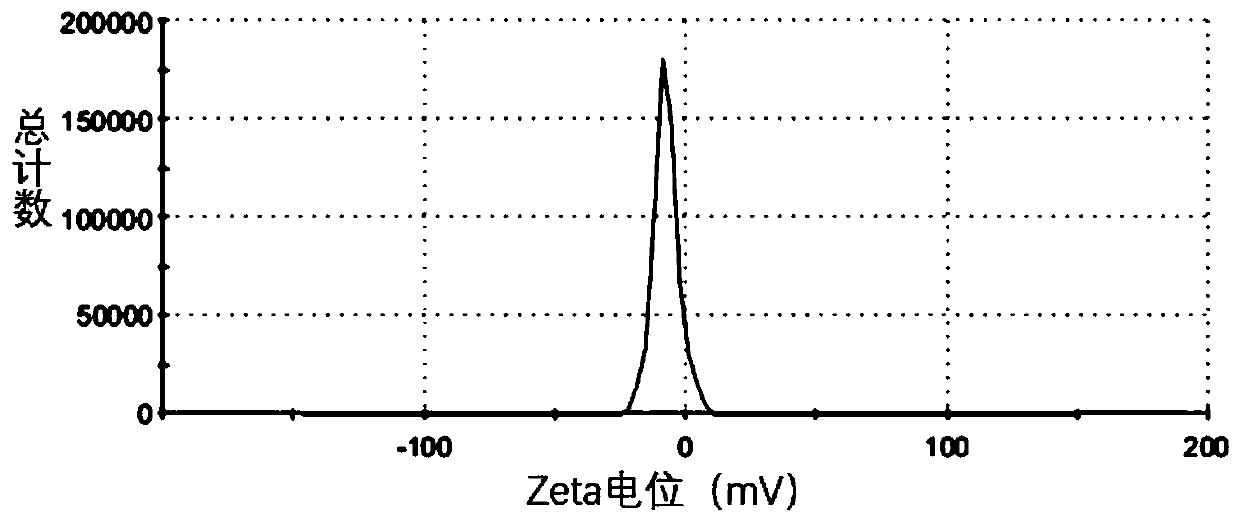

| particle diameter | aaaaa | aaaaa |

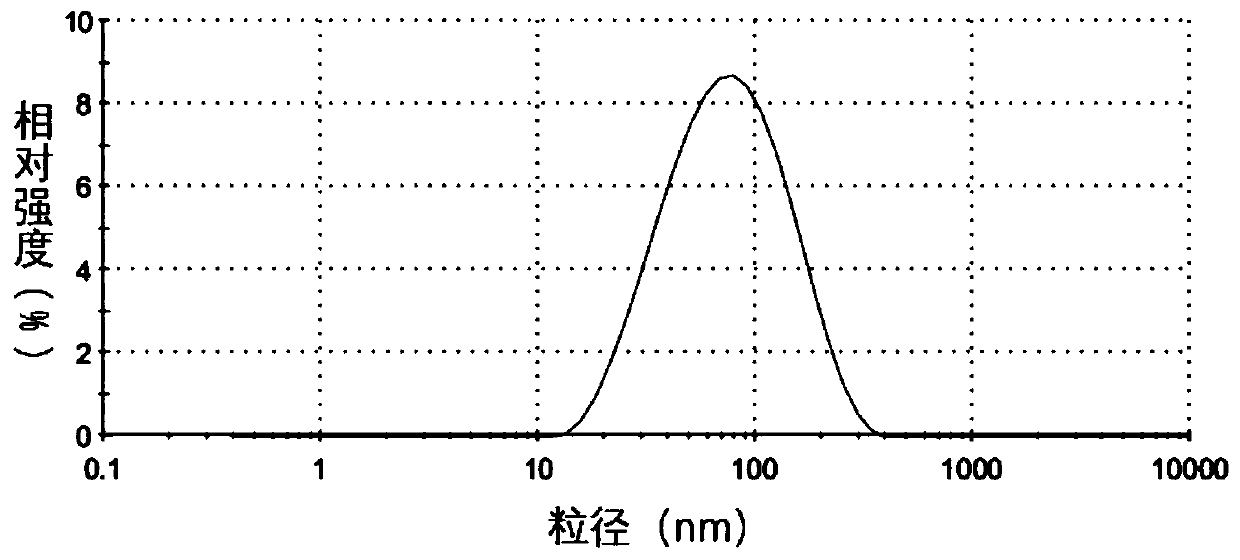

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com