Method of laser-MIG electric arc hybrid welding of low nickel nitrogen-containing austenitic stainless steel

An austenitic stainless steel, composite welding technology, applied in laser welding equipment, welding equipment, welding/welding/cutting objects, etc., can solve the problems of high probability of porosity and poor stability of welded joints, and achieve a flat hardness distribution trend and thermal stability. The effect of a small area of influence and no tendency to harden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

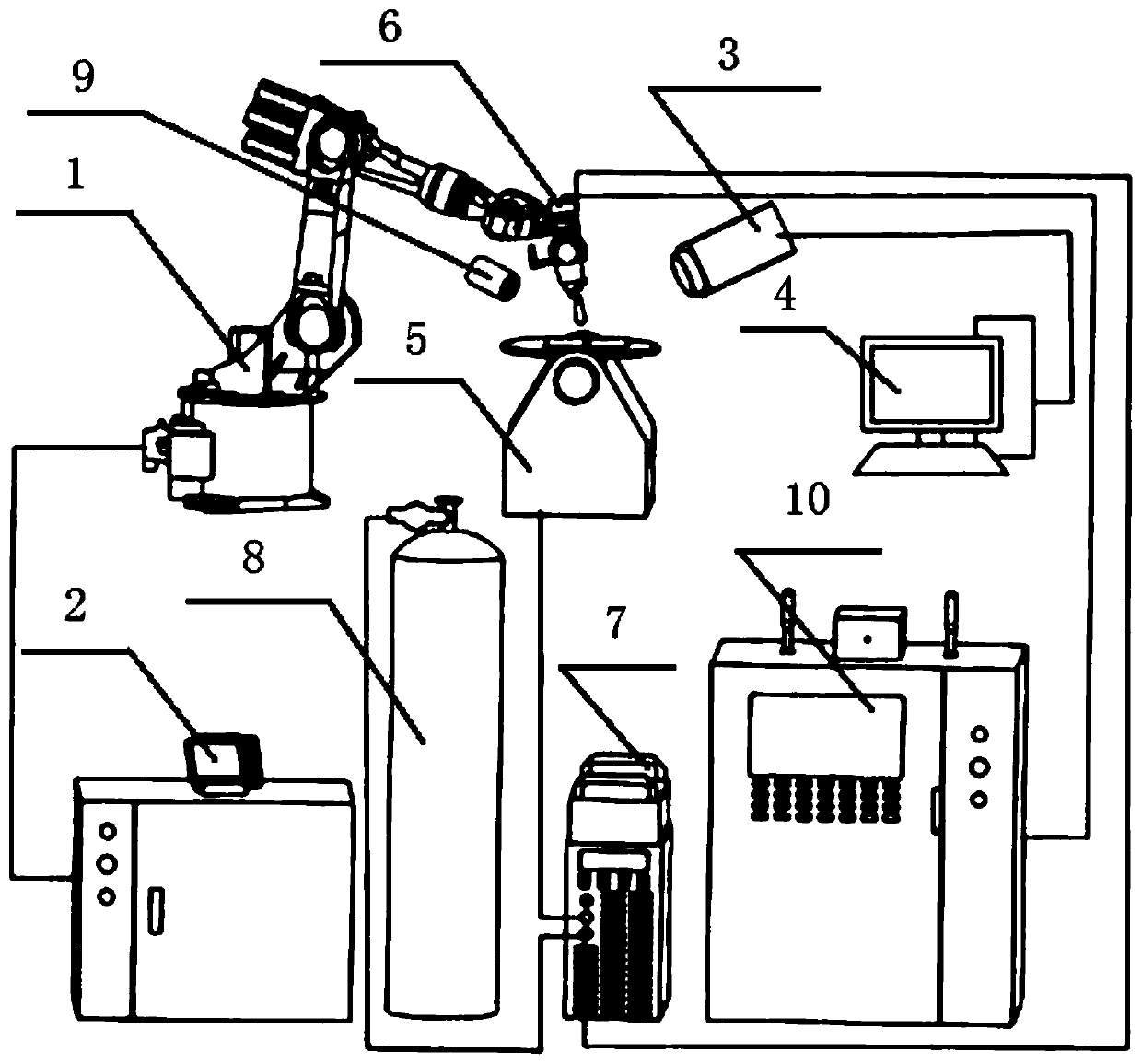

[0034] Embodiment 1: A method of laser-MIG arc hybrid welding of low-nickel nitrogen-containing austenitic stainless steel in this embodiment is carried out according to the following steps:

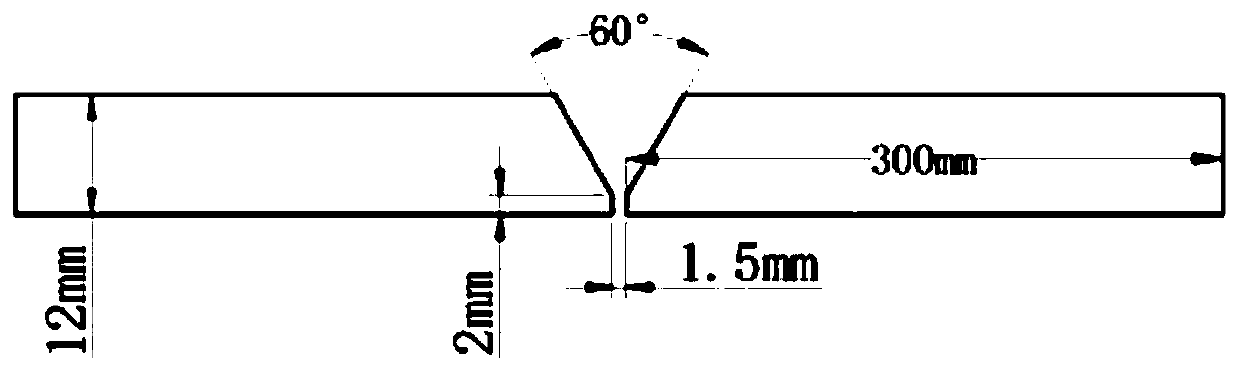

[0035] 1. Set the steel plate to be welded (300mm×150mm×12mm) into a butt joint with a joint gap of 1.5mm, and process a V-shaped groove with a groove angle of 60° and a blunt edge thickness of 2mm;

[0036] 2. Set the composite welding shielding gas as a mixed gas of nitrogen and argon, and the volume fraction of nitrogen in the mixed gas is 2%;

[0037] 3. Simultaneously carry out the composite welding of laser and MIG arc, the process parameters of the laser welding: the laser power is 2500W, the welding speed is 6.7mm / s, the defocus is +20mm, and the laser incident angle is 6°; the MIG The process parameters of arc welding: the gas flow rate is 20L / min, the welding current is 180A, the welding voltage is 28V, the dry elongation of the welding wire is 18mm, and the angle of the weldin...

specific Embodiment approach 2

[0043] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the process parameters of the laser welding: the laser power is 3000W, and the welding speed is 8.2mm / s; the process parameters of the MIG arc welding: the welding current is 200A, welding voltage is 28.5V. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0044] Specific embodiment three: the difference between this embodiment and specific embodiment one is: the process parameters of the laser welding: the laser power is 3500W, and the welding speed is 8.7mm / s; the process parameters of the MIG arc welding: the welding current is 240A, welding voltage is 29.3V. Other steps and parameters are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com