Adult pad towel for preventing bedsore

A technology for adults and pads, which is applied in personal care, rayon manufacturing, and peptide preparation methods. It can solve problems such as unsuitable for large-scale promotion and use, difficulty in unifying process standards, and complicated preparation of wet wipes, so as to increase contact comfort. High degree, low cost, increase the effect of elasticity and activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

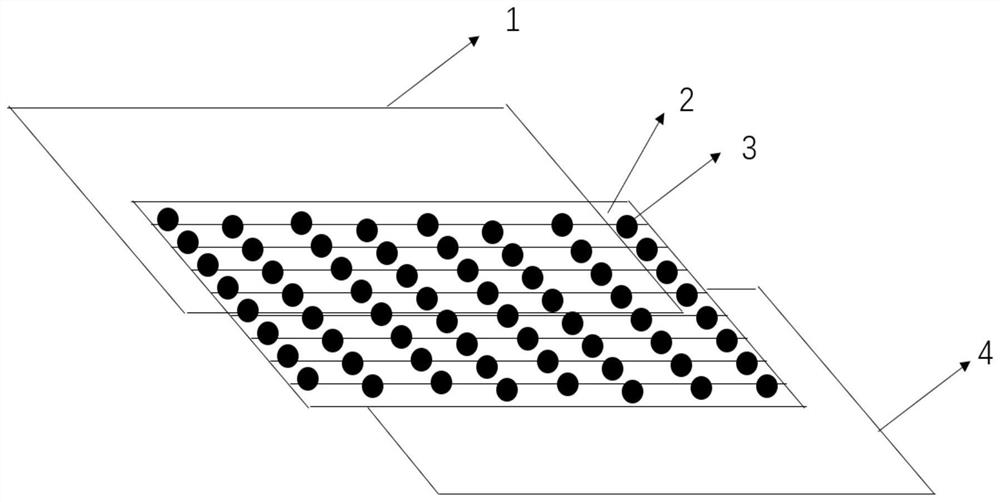

Image

Examples

Embodiment 1

[0019] The synthesis of embodiment 1 antimicrobial peptide

[0020] The 9-fluorenylmethoxycarbonyl (Fmoc) synthesis strategy was used to synthesize from the C-terminal to the N-terminal. 10mg of Rink-Amide-Resin resin (AAPPTec, product number RRZ001) was used as a carrier, and the active group of the carrier itself was connected to the carboxyl group of 5mg of the first amino acid (Fmoc-S-NH2) protected by Fmoc.

[0021] Rinse the resin with N-methylpyrrolephrine (NMP) to remove redundant protected amino acids, add 20% piperidine / NMP solution (volume fraction) to the reactor (solid phase synthesizer) to remove the Fmoc group, react for 20min, Empty the reactor, wash the resin with 5mL NMP shaking, repeat 3 times, remove the Fmoc protection of the first amino acid residue; the exposed active amino group is connected to the carboxyl group of the next amino acid (5mg) that is amino-protected by Fmoc , forming the first peptide bond (S-V). The above steps in this section are rep...

Embodiment 2

[0022] Embodiment 2 The preparation of antibacterial and anti-inflammatory soft layer

[0023] Mix the polypeptide prepared in Example 1 with the spinning solution prepared by 25 parts of spinnable cotton fiber, 15 parts of modified fiber, 15 parts of silk fiber, 30 parts of bamboo fiber and 10 parts of soybean protein fiber to form a polypeptide and the mixed spinning solution of the spinning solution, wherein the content of the polypeptide in the spinning solution is 1 wt%, the concentration of the spinning solution is 30%, and the viscosity is 30 seconds. The mixed spinning solution obtained in the above steps is subjected to spinning and post-treatment to obtain polypeptide regenerated fibers.

[0024] Described spinning and aftertreatment, comprise the following steps:

[0025] 1. Spinning, the mixed spinning liquid obtained in the above steps is filtered, defoamed, and matured, then sent to the spinning machine, and extruded from the spinneret hole of the spinneret of t...

Embodiment 3

[0028] The preparation of embodiment 3 water-absorbing layer

[0029] The preparation of the water-absorbing layer is prepared by the following process: A) Prepare the anti-adhesion layer, put the medical non-toxic grade polyethylene pellets into the screw extruder to melt and extrude, and successively flow into a film, roll out the anti-adhesion hole, cool and Winding to obtain a medical non-toxic grade polyethylene film as an anti-adhesion layer; B) preparing a liquid-absorbing layer, which will be 50-90 parts by weight of viscose fiber and 10-50 parts by weight of superabsorbent fiber The mixed mixed fibers are sequentially opened by an opener, carded by a carding machine, laid by a web machine and needled by a needle punching machine to obtain a non-woven fabric as a liquid-absorbing layer; C) prepare a waterproof and breathable layer, and the polyurethane particles Throw into the screw extruder and melt and extrude and successively form a film through casting, cooling and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com