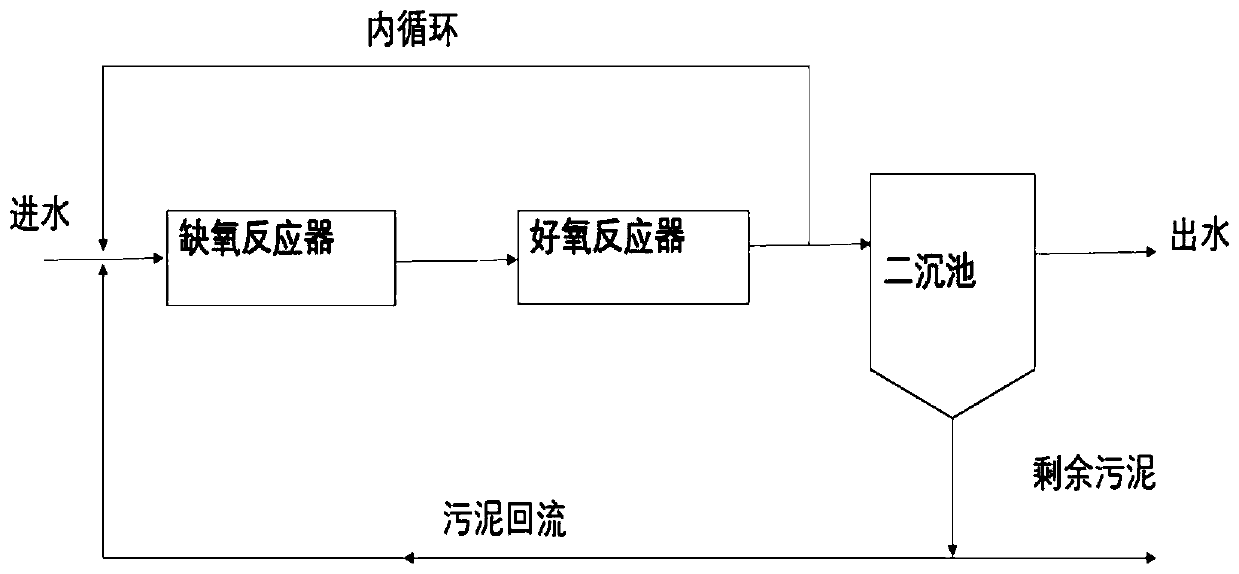

Method for improving denitrification efficiency of A/O sewage treatment system under low carbon-nitrogen ratio condition

A technology for sewage treatment system and denitrification efficiency, applied in the field of water treatment, can solve the problems of timely adjustment, inconvenient operation, etc., and achieve the effect of improving the removal rate, improving the removal effect, and improving the removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

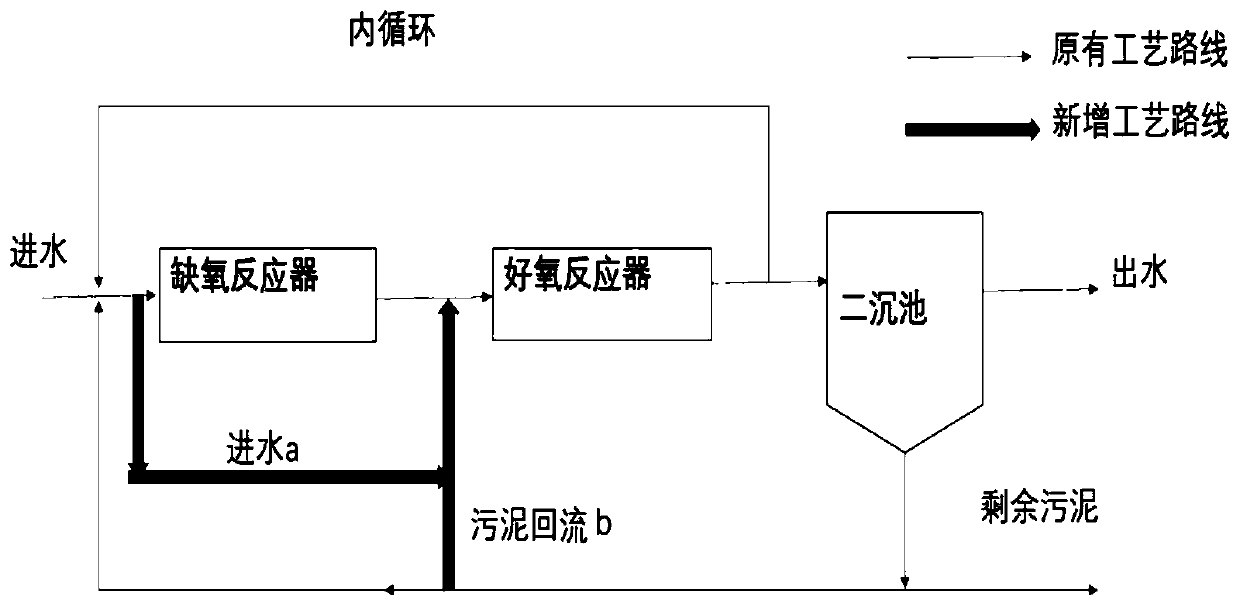

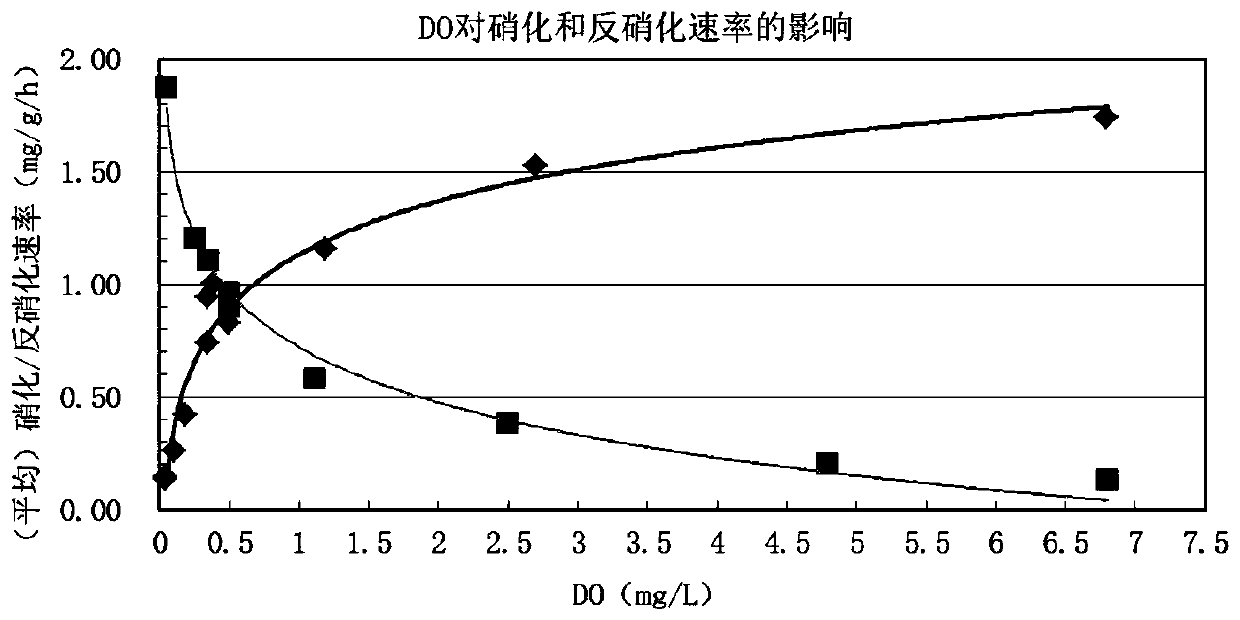

[0079] Example 1. A sewage treatment plant adopts the A / O process with a daily processing capacity of 2 tons / day. The hydraulic retention time of A / O is 4h and 12h respectively. The weekly average influent COD is 150mg / L and ammonia nitrogen is 28.0 mg / L, total nitrogen TN is 35.0mg / L. The average weekly effluent COD is 15mg / L, ammonia nitrogen is 2.2mg / L, total nitrogen TN is 12.80mg / L. 20L / h of influent sewage directly enters the aerobic aeration tank to increase the sludge return flow of the secondary settling tank, and the ratio of the return sludge of the secondary settling tank into the anaerobic tank and the aerobic tank is 1.0. Adjust the sludge concentration in the aeration tank from 3700mg / L to 11200mg / L, without changing the aeration volume in the aeration tank, and control the dissolved oxygen at 2.5-4.60mg / L. After the system runs stably, the weekly average effluent COD is 12mg / L, ammonia nitrogen is 0.22mg / L, total nitrogen TN is 7.6mg / L, total phosphorus is 0.20...

Embodiment 2

[0080] Example 2. A sewage treatment plant adopts the A / O process with a daily processing capacity of 60,000 tons / day. The hydraulic retention time of A / O is 4h and 9h respectively. The weekly average influent COD is 205.1mg / L, and the ammonia nitrogen is 24.88mg / L, total nitrogen TN is 32.50mg / L, total phosphorus 3.45mg / L. The average weekly effluent COD was 35mg / L, ammonia nitrogen was 0.69mg / L, total nitrogen TN was 14.50mg / L, total phosphorus was 0.49mg / L. The above process is adjusted, and 700 tons / hour of influent sewage directly enters the aerobic aeration tank (1800 tons / hour still enters the anaerobic reactor from the front end), and increases the sludge return flow in the secondary settling tank. The ratio of the return sludge into the anaerobic tank and the aerobic tank in the secondary settling tank is 0.8. The sludge concentration in the aeration tank is adjusted from 3700mg / L to 8800mg / L without changing the aeration volume in the aeration tank. The internal MLSS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com