Elegant golden sand

A gold sand and elegant gold technology, applied in the field of elegant gold sand, can solve the problems of occupying wall area, thick tiles, heavy weight, etc., and achieve the effects of resisting wall scratches, reducing wall bearing capacity, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

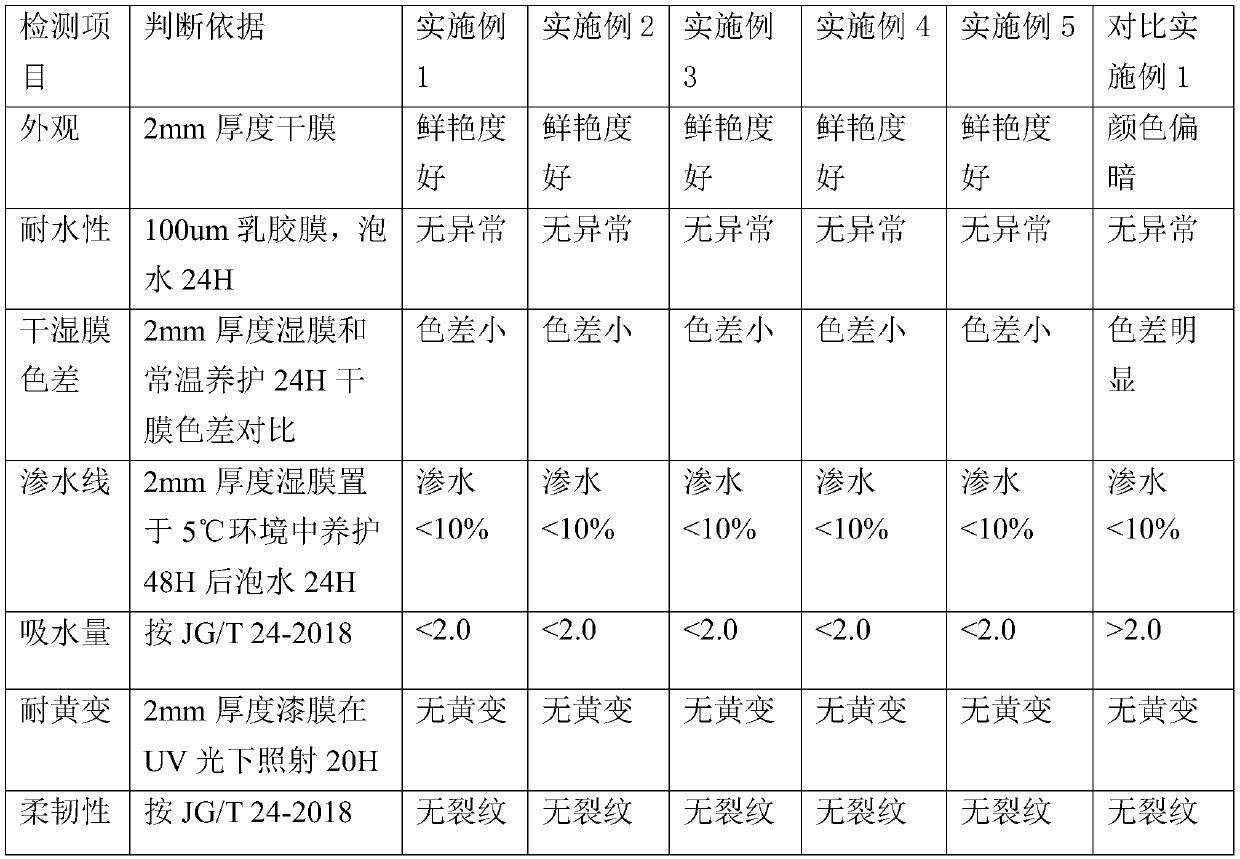

Examples

Embodiment 1

[0016] A kind of elegant golden sand, comprising the following raw materials in mass percentage: 10% of water, 16% of pure acrylic emulsion, 2% of wax emulsion, 69.9% of coated colored sand, 0.3% of cellulose, 0.4% of antifreeze, and preservative 0.05%, antifungal agent 0.35%, film-forming aid 0.8%, PH value regulator 0.1%, thickener 0.1%.

[0017] The preparation method of the coated colored sand is as follows:

[0018] Step 1): Mix and stir pure acrylic silicone emulsion 94.2%-94.5% and film-forming aid 5.5-5.8% by mass percentage in summer to obtain a mixed solution;

[0019] Step 2): Stir the colored sand and the mixture obtained above at a ratio of 1:0.05-0.15 until uniform, then dry at 30-40°C, stir once every 0.2-2H during the drying process, until it reaches a constant weight , then pulverized, then dried to constant weight, and sieved to obtain coated colored sand.

Embodiment 2

[0021] A kind of elegant golden sand, comprising the following raw materials in mass percentage: 8% of water, 17.5% of pure acrylic emulsion, 2% of wax emulsion, 70% of coated colored sand, 0.2% of cellulose, 0.6% of antifreeze, and preservative 0.05%, antifungal agent 0.45%, film-forming aid 1%, PH value regulator 0.12%, thickener 0.08%.

[0022] The preparation method of coated colored sand is the same as that in Example 1.

Embodiment 3

[0024] An elegant golden sand, comprising the following raw materials in mass percentage: 12% of water, 18% of pure acrylic emulsion, 2% of wax emulsion, 65% of coated colored sand, 0.4% of cellulose, 0.52% of antifreeze, and preservative 0.06%, antifungal agent 0.6%, film-forming aid 1.2%, PH value regulator 0.12%, thickener 0.1%.

[0025] The preparation method of the coated colored sand is as follows:

[0026] Step 1): In winter, mix 93.5%-94.2% of pure acrylic silicone emulsion and 5.8-6.5% of film-forming aid according to mass percentage and stir evenly to obtain a mixed solution;

[0027] Step 2): Then mix and stir the colored sand and the above-mentioned mixed solution at a ratio of 1:0.15-0.25 until uniform, then dry at 30-40°C, and stir once every 0.2-2H during the drying process until it reaches a constant temperature. weight, then crushed, then dried to constant weight, and sieved to obtain coated colored sand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com