Vacuum diffusion welding method for protective layer of miniature high-temperature oxygen concentration sensor

An oxygen concentration sensor and vacuum diffusion welding technology, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of inability to realize the miniaturization of the structure, crack failure in the middle layer, and low heating temperature, so as to meet the requirements of stability and high Oxygen measurement accuracy requirements, low heating temperature, and the effect of uniform solder spreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

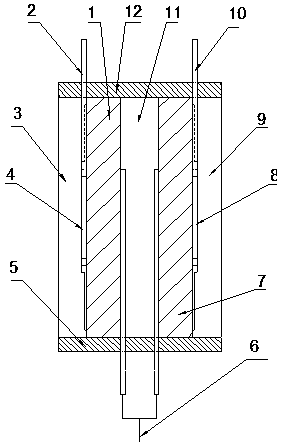

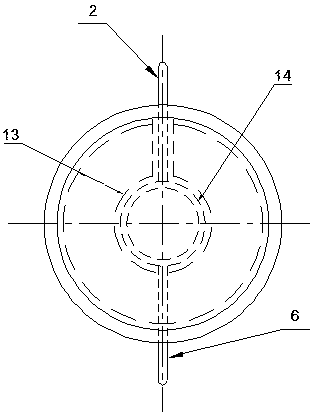

[0020] In this embodiment, an alumina ceramic sheet with a thickness of 0.4 mm and a diameter of 5.5 mm and a zirconia ceramic sheet with a thickness of 0.6 mm and a diameter of 5.5 mm are used as workpieces to be welded. 2.2mm, outer diameter 5.2mm, depth 0.095mm annular groove, the specific structure is shown in the schematic diagram of the sensor structure ( figure 1 ) and a schematic diagram of the structure of the alumina ceramic protective layer ( figure 2 ). Two kinds of solder foils, B-Ti72Ni28 and B-Ag85Zr15, are selected and connected by vacuum diffusion welding.

[0021] The specific vacuum diffusion welding process steps of the alumina / zirconia ceramic structure of the miniature oxygen concentration sensor protective layer are as follows:

[0022] (1) Two brazing foils, B-Ti72Ni28 with a thickness of 0.05mm and B-Ag85Zr15 with a thickness of 0.06mm, were selected to form a ring structure with an inner diameter of 2.2mm and an outer diameter of 5.2mm;

[0023] (...

Embodiment 2

[0028] In this embodiment, an alumina ceramic sheet with a thickness of 0.4 mm and a diameter of 5.5 mm and a zirconia ceramic sheet with a thickness of 0.6 mm and a diameter of 5.5 mm are used as workpieces to be welded. 2.2mm, outer diameter 5.2mm, depth 0.095mm annular groove, the specific structure is shown in the schematic diagram of the sensor structure ( figure 1) and a schematic diagram of the structure of the alumina ceramic protective layer ( figure 2 ). Two kinds of solder foils, B-Ti72Ni28 and B-Ag85Zr15, are selected and connected by vacuum diffusion welding.

[0029] The specific vacuum diffusion welding process steps of the alumina / zirconia ceramic structure of the miniature oxygen concentration sensor protective layer are as follows:

[0030] (1) Two brazing foils, B-Ti72Ni28 with a thickness of 0.05mm and B-Ag85Zr15 with a thickness of 0.06mm, were selected to form a ring structure with an inner diameter of 2.2mm and an outer diameter of 5.2mm;

[0031] (2...

Embodiment 3

[0036] In this embodiment, an alumina ceramic sheet with a thickness of 0.4 mm and a diameter of 5.5 mm and a zirconia ceramic sheet with a thickness of 0.6 mm and a diameter of 5.5 mm are used as workpieces to be welded. 2.2mm, outer diameter 5.2mm, depth 0.095mm annular groove, the specific structure is shown in the schematic diagram of the sensor structure ( figure 1 ) and a schematic diagram of the structure of the alumina ceramic protective layer ( figure 2 ). Two kinds of solder foils, B-Ti72Ni28 and B-Ag85Zr15, are selected and connected by vacuum diffusion welding.

[0037] The specific vacuum diffusion welding process steps of the alumina / zirconia ceramic structure of the miniature oxygen concentration sensor protective layer are as follows:

[0038] (1) Two brazing foils, B-Ti72Ni28 with a thickness of 0.05mm and B-Ag85Zr15 with a thickness of 0.06mm, were selected to form a ring structure with an inner diameter of 2.2mm and an outer diameter of 5.2mm;

[0039] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com