Preparation method of magnetic covalent organic framework molecularly imprinted polymer for separating anthocyanin

A covalent organic framework, molecular imprinting technology, applied in the directions of alkali metal compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problem of low selectivity of separation fillers, and achieve the goal of improving separation efficiency, preventing collapse and ensuring accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0052] Embodiment 1: In this embodiment, a method for preparing a magnetic covalent organic framework molecularly imprinted polymer for separating anthocyanins is carried out according to the following steps:

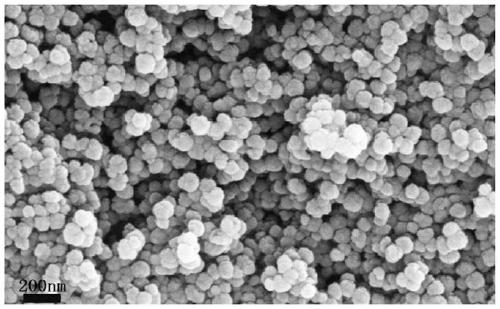

[0053] 1. Superparamagnetic amino functionalized Fe 3 o 4 Preparation of magnetic nanoparticles: 13.50 g of FeCl 3 ·6H 2 O was added to 500mL of ethylene glycol, ultrasonicated at a frequency of 40kHz for 30min until completely dissolved, then 27g of anhydrous sodium acetate and 172mL of 1,6-hexamethylenediamine were added, and mechanically stirred at a stirring speed of 150rpm 30min until a reddish-brown solution is obtained, react the obtained reddish-brown solution at a temperature of 200°C for 6h, then carry out magnetic separation and sedimentation with a strong magnet, wash the separated solid matter, first wash 5 times with double distilled water, and then use After washing with ethanol for 5 times to remove unreacted substances, vacuum drying was carried out ...

specific Embodiment approach 2

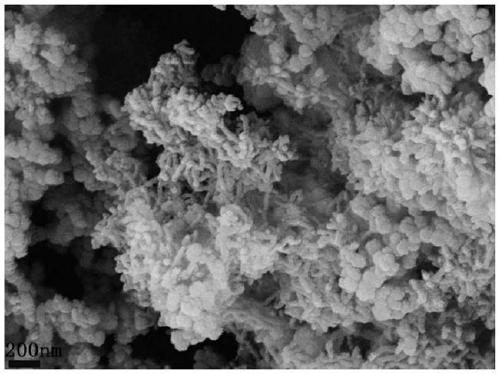

[0055] Embodiment 2: This embodiment differs from Embodiment 1 in that: the functional monomer is p-diaminobiphenyl (BD), and the obtained magnetic covalent organic framework molecularly imprinted polymer is MCMIPs-BD. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

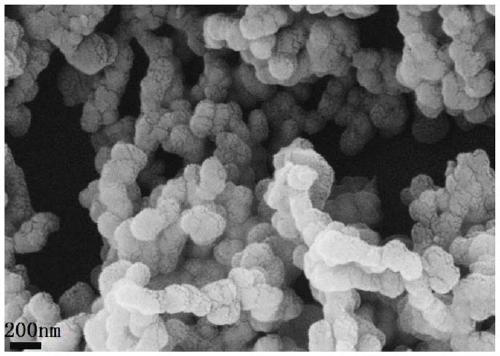

[0056] Embodiment 3: This embodiment is different from Embodiment 1 in that: the functional monomer is 3,3'-dihydroxybenzidine (DHBD), and the obtained magnetic covalent organic framework molecularly imprinted polymer is MCMIPs-DHBD. Other steps and parameters are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com