New method used for extracting metal nickel from laterite-nickel ore leach liquor

A technology for laterite nickel ore and metal extraction, which is applied in the direction of improving process efficiency, can solve problems such as inoperability and production practice, and achieve the effects of reducing production costs, improving production reliability, and reducing waste water discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

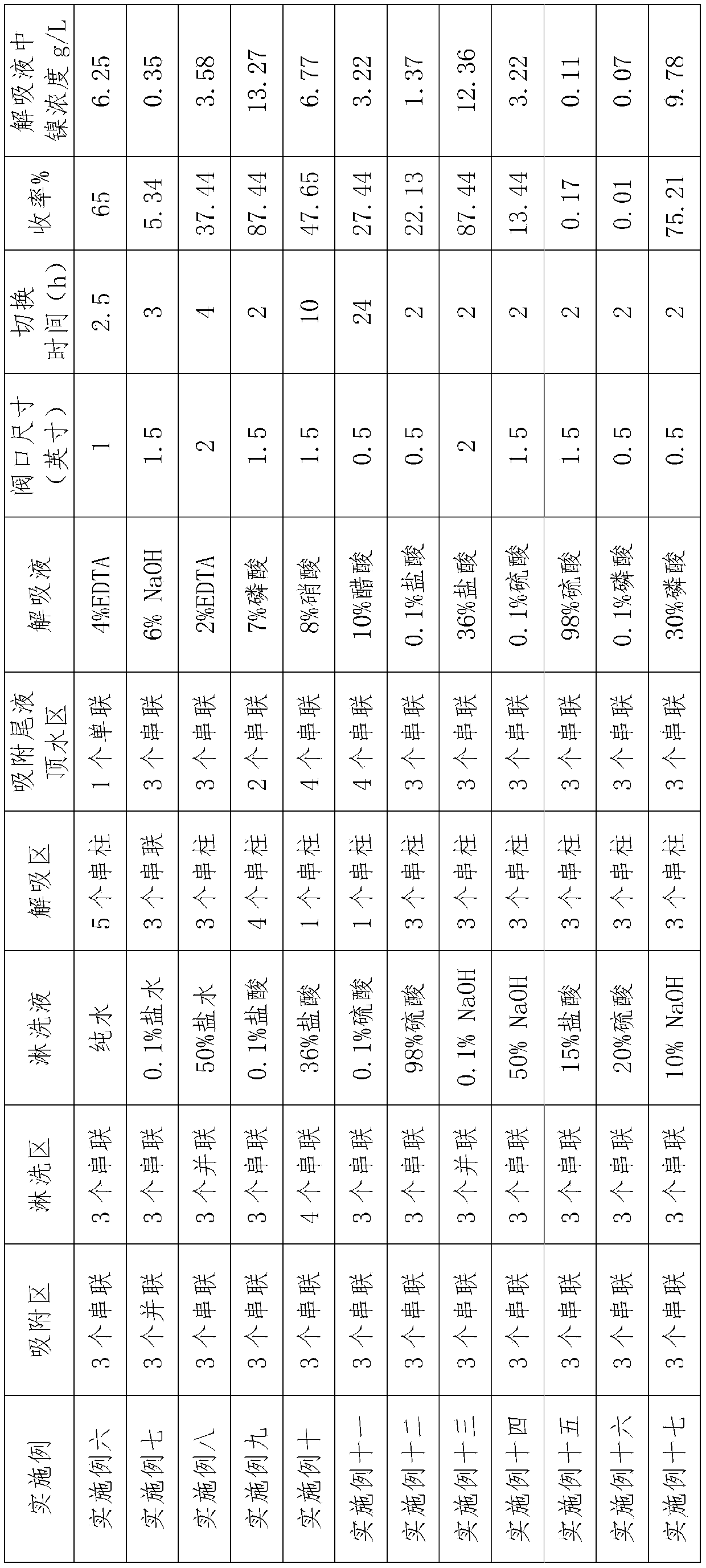

Examples

Embodiment 1

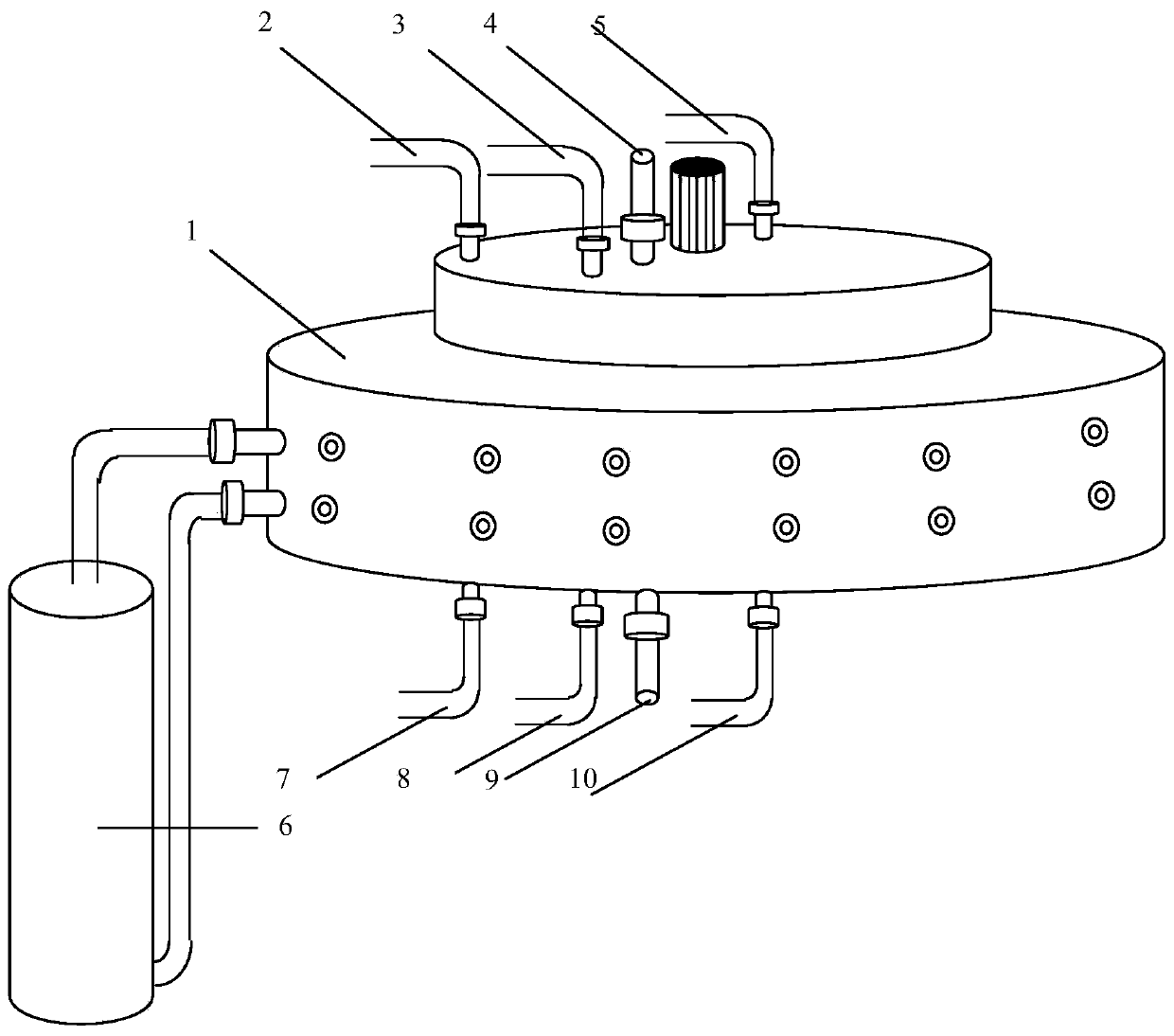

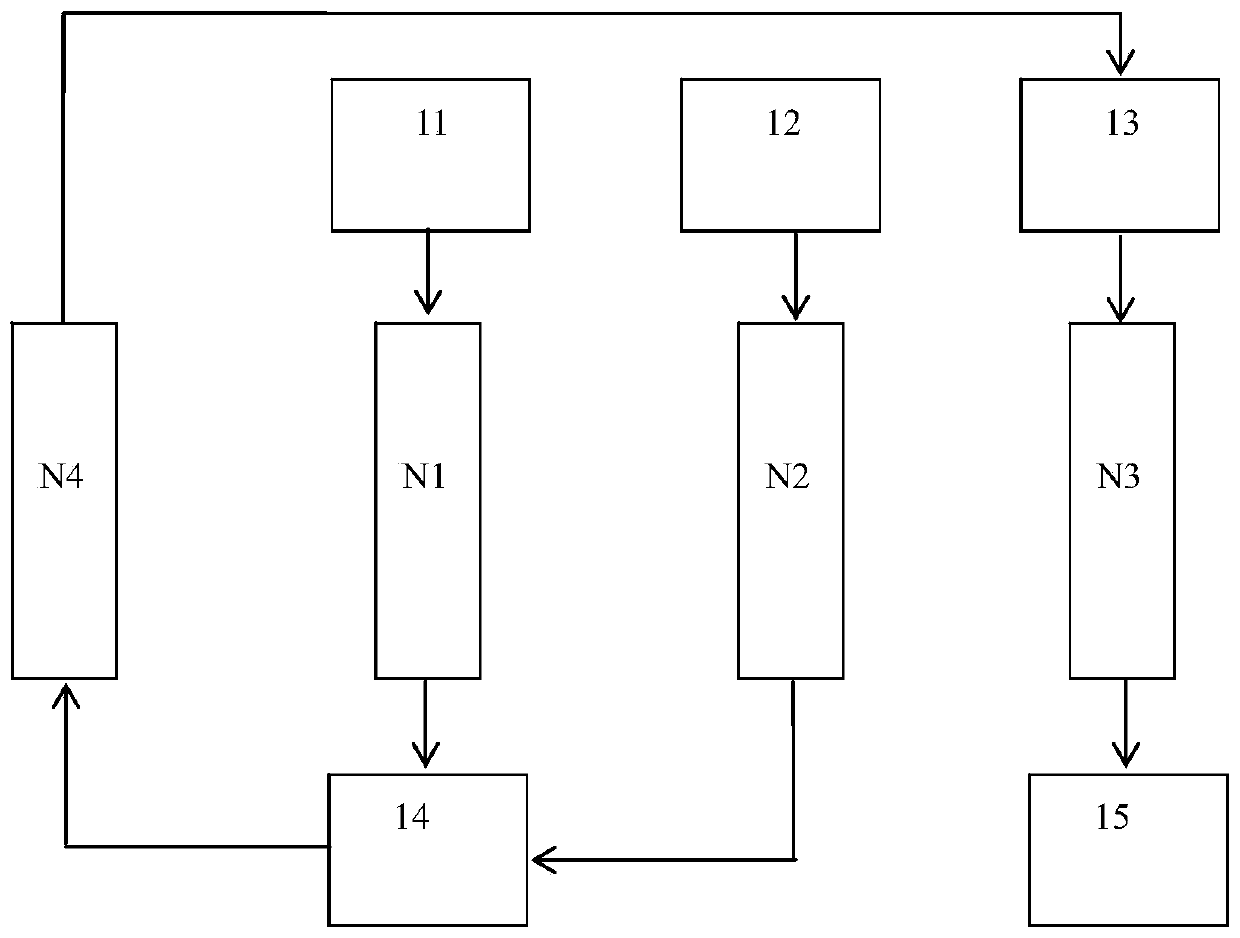

[0046]Laterite nickel ore leaching solution, eluent-pure water, desorption solution-15% (W / W) sulfuric acid aqueous solution, and desorption qualified solution respectively pass through the rotary switching valve system 1 located in the channel (the diameter of the valve port is 1.5 inches, and the rotation switching time 1h) Feed pipe 3 for laterite nickel ore leaching liquid, feed pipe 4 for eluent, feed pipe 5 for desorption liquid, feed pipe 7 for desorption liquid on the top and bottom of the turntable, through the channel to rotate and switch the inner channel of the valve system After entering the corresponding resin column 6 with the channel respectively (filling Lanxiao Technology to extract nickel chelating resin LSC-930, produced by Xi'an Lanxiao Technology New Materials Co., Ltd.), from the laterite nickel ore leaching solution discharge pipe 8, The eluent discharge pipe 9, the qualified liquid discharge pipe 10, and the adsorption tail liquid top desorption liquid ...

Embodiment 2

[0054] Laterite nickel ore leaching solution, eluent-pure water, desorption solution-10% (W / W) sulfuric acid aqueous solution, and desorption qualified solution pass through the rotary switching valve system 1 located in the channel (the diameter of the valve port is 1.5 inches, and the rotation switching time 3h) Feed pipe 3 for laterite nickel ore leaching liquid, feed pipe 4 for eluent, feed pipe 5 for desorption liquid, feed pipe 7 for desorption liquid on the top and bottom of the turntable, through the channel to rotate and switch the inner channel of the valve system After entering the corresponding resin column 6 with the channel respectively (filling Lanxiao Technology to extract nickel chelating resin LSC-930, produced by Xi'an Lanxiao Technology New Materials Co., Ltd.), from the laterite nickel ore leaching solution discharge pipe 8, The eluent discharge pipe 9, the qualified liquid discharge pipe 10, and the adsorption tail liquid top desorption liquid discharge pi...

Embodiment 3

[0062] Laterite nickel ore leaching solution, eluent-pure water, desorption solution-18% (w / w) sulfuric acid aqueous solution, and desorption qualified solution respectively pass through the rotary switching valve system 1 located in the channel (the diameter of the valve port is 1.5 inches, and the rotation switching time 2h) Feed pipe 3 for laterite nickel ore leaching liquid, feed pipe 4 for eluent, feed pipe 5 for desorption liquid, feed pipe 7 for desorption liquid on the top and bottom of the turntable, through the channel to rotate and switch the inner channel of the valve system After entering the corresponding resin column 6 with the channel respectively (filling Lanxiao Technology to extract nickel chelating resin LSC-930, produced by Xi'an Lanxiao Technology New Materials Co., Ltd.), from the laterite nickel ore leaching solution discharge pipe 8, The eluent discharge pipe 9, the qualified liquid discharge pipe 10, and the adsorption tail liquid top desorption liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com