Growth method of calcium fluoride single crystal and used device

A growth method, calcium fluoride technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of small single crystal rate of stress birefringence, low single crystal yield, high crystal structure requirements, etc., to achieve Improved yield and crystal quality, low stress birefringence, and high single crystal transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

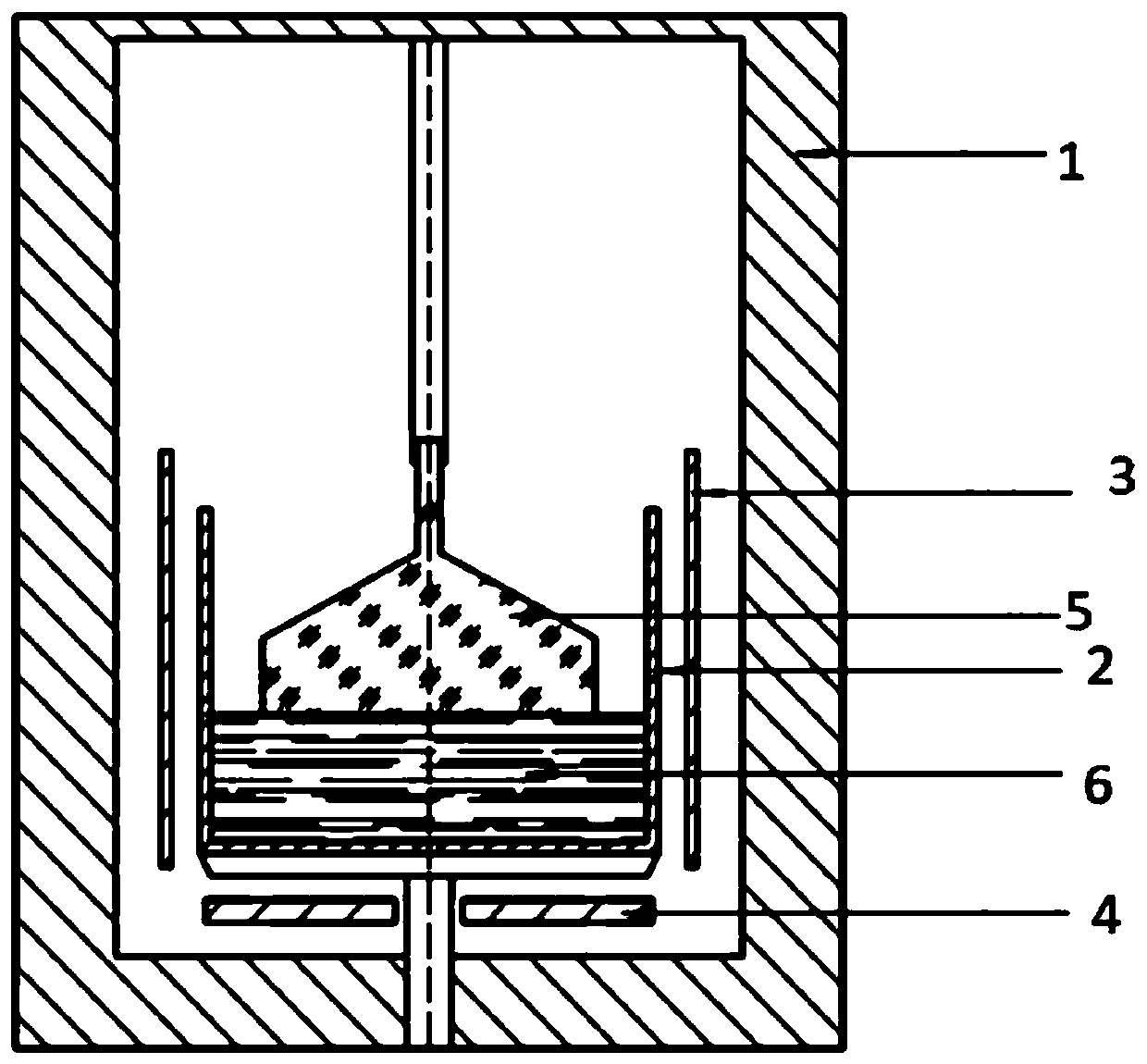

[0034] A method for growing a calcium fluoride single crystal, using calcium fluoride as a raw material, and using a crucible pulling method to grow a calcium fluoride single crystal, wherein the device used in the crucible pulling method is provided with a side heater on the side of the crucible, There is a bottom heater at the bottom. The raw material calcium fluoride is ultraviolet grade, and the purity is 99.99%.

[0035] The growth method includes the following steps:

[0036] S1 Load the raw materials into the graphite crucible, and evacuate until the vacuum degree reaches (or higher than) 10 -2 Pa;

[0037] The S2 side heater and the bottom heater are both heated at 50°C / h at the same time, and the temperature of the side heater and the bottom heater are both raised to 150°C, and the temperature is kept constant for 48 hours (the process of heating and constant temperature also plays a role in removing the heat in the device. the action of water vapor), until the int...

Embodiment 2

[0046] Example 2 is basically the same as Example 1 above, except that in step S4 of the calcium fluoride single crystal growth method, the side heater is heated to 1400°C and then kept at a constant temperature, the bottom heater is heated to 1250°C and kept at a constant temperature, the side heater and After the temperature of the bottom heater is stabilized, the temperature is kept at a constant temperature for more than 5 hours, until the raw material is melted and the melt temperature in the crucible reaches equilibrium, and the seed crystals are fused; the heating rates of the side heater and the bottom heater are 50°C / h and 30°C / h respectively; The orientation of the seed crystal is .

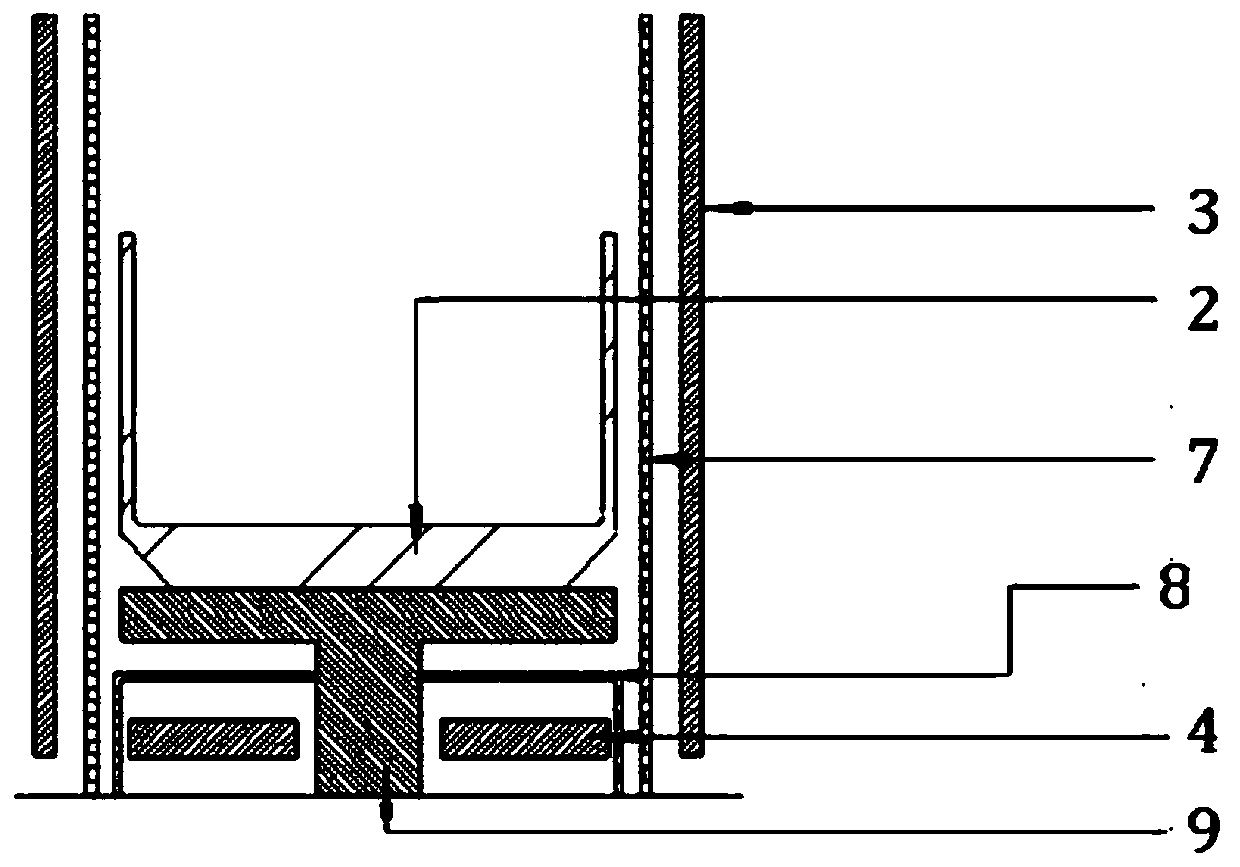

[0047] The device used for the growth of calcium fluoride single crystal is basically the same as that in Example 1, the difference is that a circle of side soaking rings 7 (such as figure 2 shown).

Embodiment 3

[0049] Example 3 is basically the same as Example 1 above, except that in step S4 of the calcium fluoride single crystal growth method, the side heater is heated to 1390°C and then kept at a constant temperature, the bottom heater is heated to 1230°C and kept at a constant temperature, the side heater and After the temperature of the bottom heater is stabilized, the temperature is kept at a constant temperature for more than 5 hours, until the raw material is melted and the melt temperature in the crucible reaches equilibrium, and the seed crystals are fused; the heating rates of the side heater and the bottom heater are 50°C / h and 30°C / h respectively; The orientation of the seed crystal is ;

[0050] The device used for the growth of calcium fluoride single crystal is basically the same as that in Example 1, the difference is that a side heating ring 7 is arranged between the side heater 3 and the crucible 2, and a bottom heating ring is arranged between the bottom heater 4 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com