System used for vibration reduction and capable of changing structural rigidity

A technology of structural stiffness and magnetorheology, applied in the functional characteristics of spring/shock absorber, design features of shock absorber, spring/shock absorber, etc., can solve the problem of increasing design cost, component manufacturing cost, mold cost, installation and transportation cost and maintenance costs, the weak ability of the mechanical structure to resist vibration, and the non-universal working environment, etc., to achieve the effects of low cost, wide application range, and increased rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

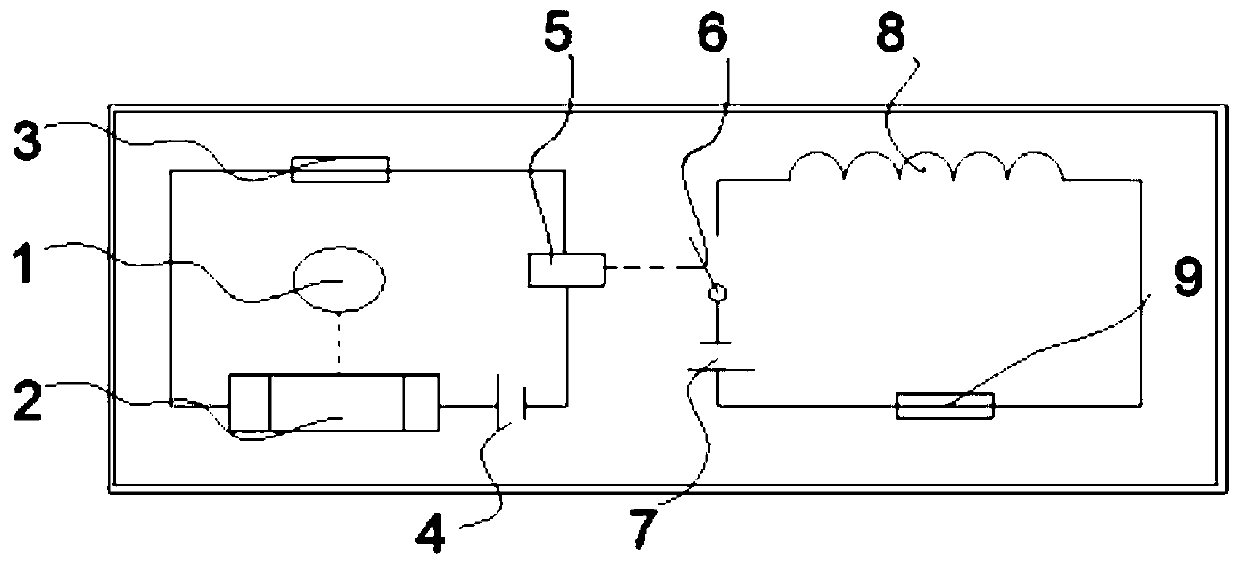

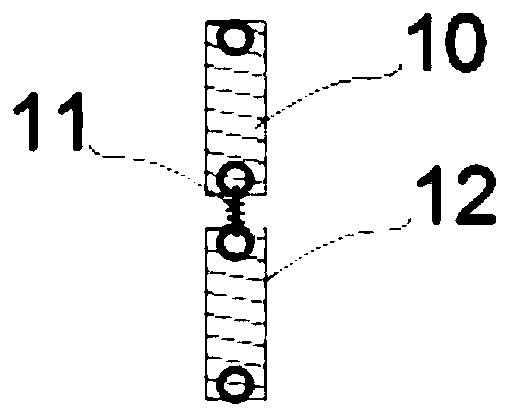

[0055] In this example, see Figure 1-Figure 4 . A system for damping vibration and capable of changing structural stiffness, including a control part, a current transmission part, and a magnetic flux sheet body;

[0056] The control part includes a sensor 1, a control unit 2, a relay 5, a control circuit power supply 4, and a control circuit fuse 3; the control unit 2, a control circuit power supply 4, a relay 5, and a control circuit fuse 3 are connected in series to form a control circuit; the sensor 1 The vibration test end is installed on the structural part to be detected, and the sensor 1 is a vibration sensor, which can perceive vibration signals;

[0057] The current transmission part includes a current transmission circuit power supply 7, a current transmission circuit fuse 9, and an electromagnetic rod 8, and forms a series current transmission series circuit. The corresponding switch 6 of the relay is arranged in the current transmission circuit, and can communica...

Embodiment 2

[0065] This embodiment is basically the same as Embodiment 1, especially in that:

[0066] In this example, if Figure 7 As shown, the system for reducing vibration and changing the structural rigidity of Embodiment 1 is installed on the tower of the wind power generator, the sensor 1 is installed on the tower structure body, and glued to the tower structure body by glue-free nails Surface; the control part is installed at the position 19 of the electric control board on the tower structure body; the current transmission part is installed at the device installation position 18 of the tower structure body, and energizes the electromagnetic rod 8.

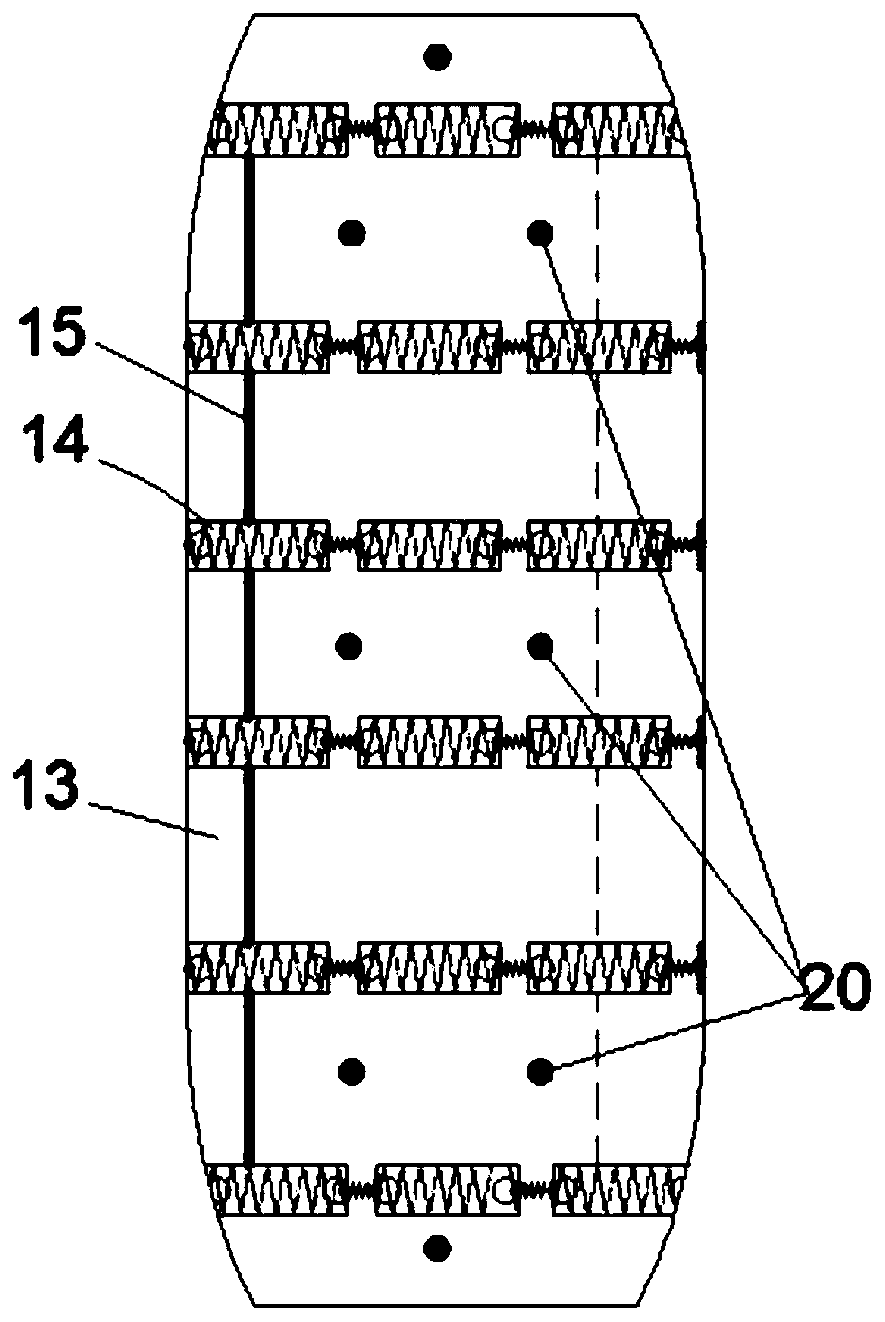

[0067] In this example, if Figure 5 with Image 6As shown, a mounting frame 16 is respectively provided near the two ends of the magnetorheological sheet 13, the magnetorheological sheet 13 is placed in the mounting frame 16, and the magnetorheological sheet 13 is pressed tightly. There are threaded holes 17 on the mounting frame ...

Embodiment 3

[0073] This embodiment is basically the same as the previous embodiment, and the special features are:

[0074] In this embodiment, the control unit 2 adopts an intelligent control algorithm to variably regulate the magnetic field applied to the corresponding magneto-rheological sheet 13 , so as to increase the stiffness of the structure as a whole or locally as required. The control process in the programmable control of the intelligent control algorithm is as follows:

[0075] First define the sliding mode function as s=B T Px, x is the velocity and displacement vectors of the lateral vibration and tangential vibration of the tower detected by the sensor; since the velocity and displacement are integral relations, that is, the time domain integral of velocity is the displacement, the other can be obtained from one quantity A quantity; where P is a 4th-order symmetric positive definite square matrix, the internal value of the P matrix is designed using the linear inequalit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com