Green antibacterial and bactericidal mask

A mask, green technology, applied in the direction of antibacterial drugs, local antibacterial agents, cosmetics, etc., can solve the problem of lack of antibacterial and sterilizing functions of the mask, and achieve the effect of improving practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

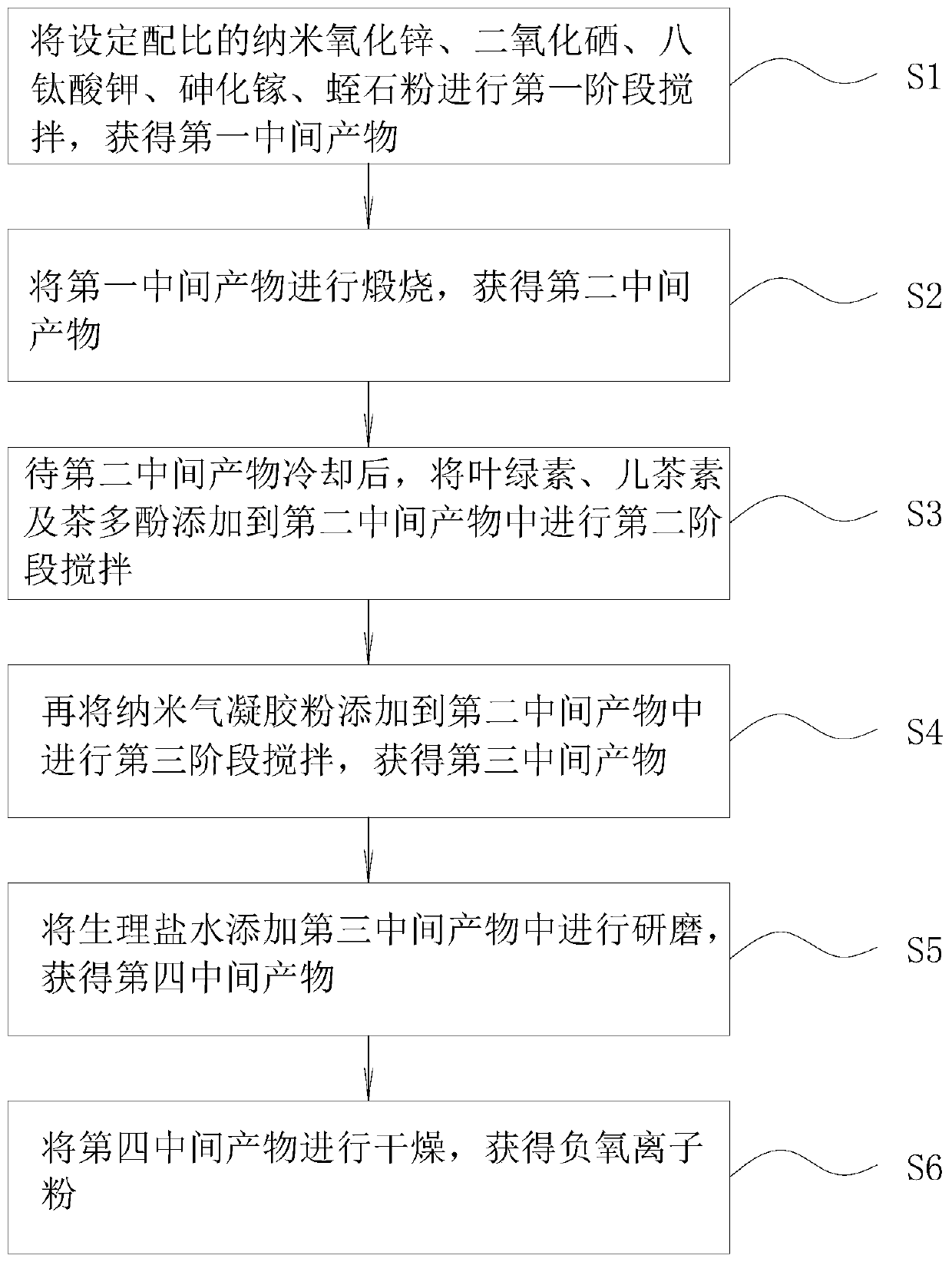

[0060] S1: Put 28 parts of nano zinc oxide powder, 1 part of selenium dioxide, 4 parts of potassium octatitanate, 0.6 parts of gallium arsenide, and 1.5 parts of vermiculite powder in a stainless steel mixing tank for the first stage of stirring to obtain the first intermediate product ; The time control of the first stage stirring is 30 minutes;

[0061] S2: placing the first intermediate product in a high-temperature furnace for calcination to obtain a second intermediate product; the calcination time is controlled to 8 hours;

[0062] S3: After the second intermediate product is cooled, put the second intermediate product in a stainless steel stirring tank, then add 19 parts of chlorophyll, 20 parts of catechin, and 10 parts of tea polyphenols into the stainless steel stirring tank for the second stage of stirring ; The time of the second stage stirring is controlled at 35 minutes;

[0063] S4: Add 8 parts of nano-airgel powder to the stainless steel stirring tank for the ...

Embodiment 2

[0067] S1: Put 30 parts of nano zinc oxide powder, 1 part of selenium dioxide, 5 parts of potassium octatitanate, 1 part of gallium arsenide, and 3 parts of vermiculite powder in a stainless steel stirring tank for the first stage of stirring to obtain the first intermediate product ; The time control of the first stage stirring is 30 minutes;

[0068] S2: placing the first intermediate product in a high-temperature furnace for calcination to obtain a second intermediate product; the calcination time is controlled to 8 hours;

[0069] S3: After the second intermediate product is cooled, put the second intermediate product in a stainless steel stirring tank, then add 20 parts of chlorophyll, 20 parts of catechin, and 10 parts of tea polyphenols into the stainless steel stirring tank for the second stage of stirring ; The time of the second stage stirring is controlled at 30 minutes;

[0070] S4: Add 10 parts of nano-airgel powder to a stainless steel stirring tank for the thir...

Embodiment 3

[0074] S1: Put 35 parts of nano zinc oxide powder, 1.3 parts of selenium dioxide, 5.5 parts of potassium octatitanate, 1.5 parts of gallium arsenide, and 3.5 parts of vermiculite powder in a stainless steel stirring tank for the first stage of stirring to obtain the first intermediate product ; The time control of the first stage stirring is 40 minutes;

[0075] S2: placing the first intermediate product in a high-temperature furnace for calcination to obtain a second intermediate product; the calcination time is controlled to 9 hours;

[0076] S3: After the second intermediate product is cooled, put the second intermediate product in a stainless steel stirring tank, then add 21 parts of chlorophyll, 22 parts of catechin, and 11 parts of tea polyphenols into the stainless steel stirring tank for the second stage of stirring ; The time of the second stage stirring is controlled at 35 minutes;

[0077] S4: Add 13 parts of nano-airgel powder to the stainless steel stirring tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com