Isophthalonitrile dry trapping device and trapping method

An isophthalonitrile, dry process technology, applied in separation methods, chemical instruments and methods, carboxylic acid nitrile purification/separation and other directions, can solve the problems of frequent start and stop, sticky materials on the inner wall, difficult handling, etc., to meet production requirements. Production demand, reduce sticking phenomenon, increase the effect of heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

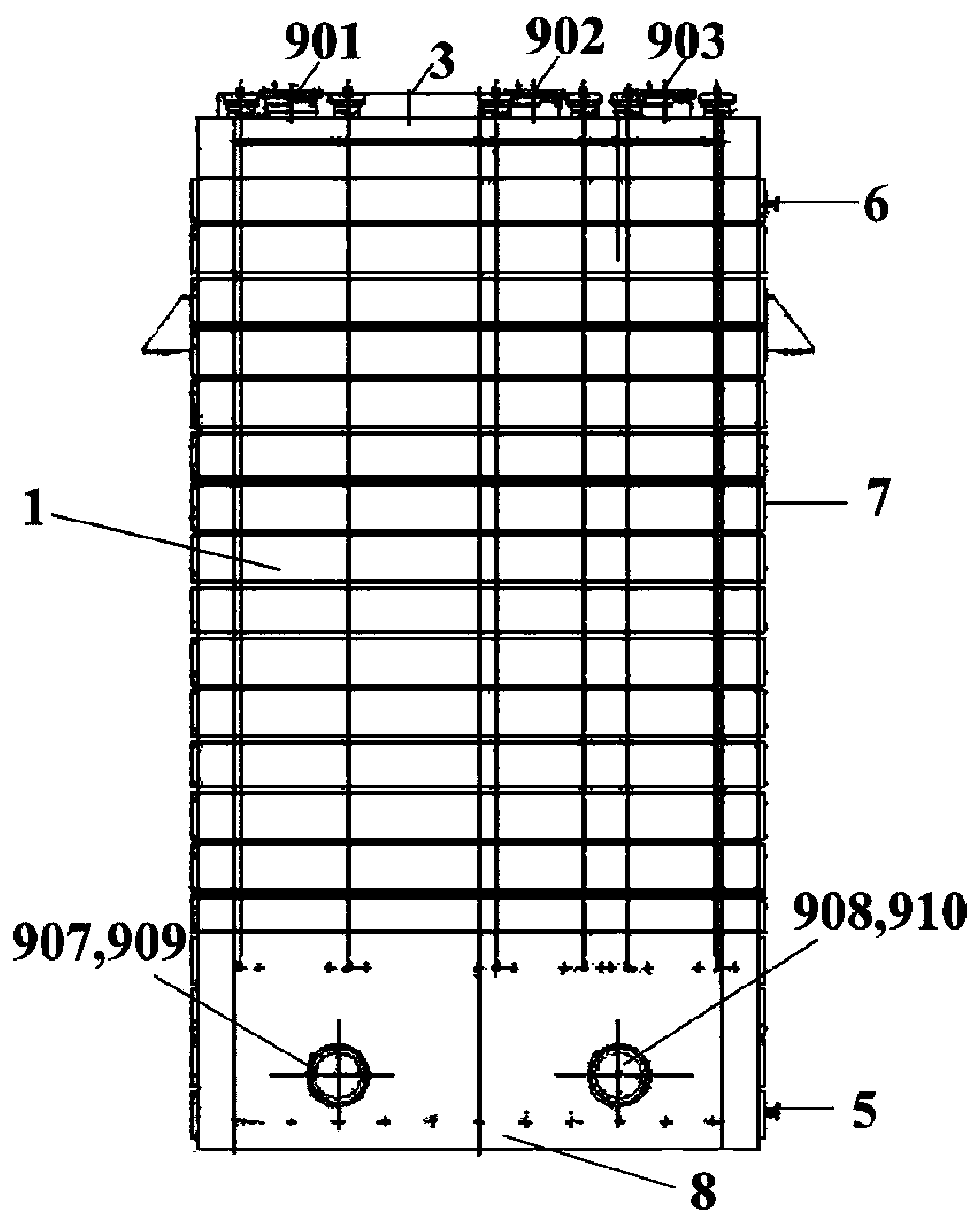

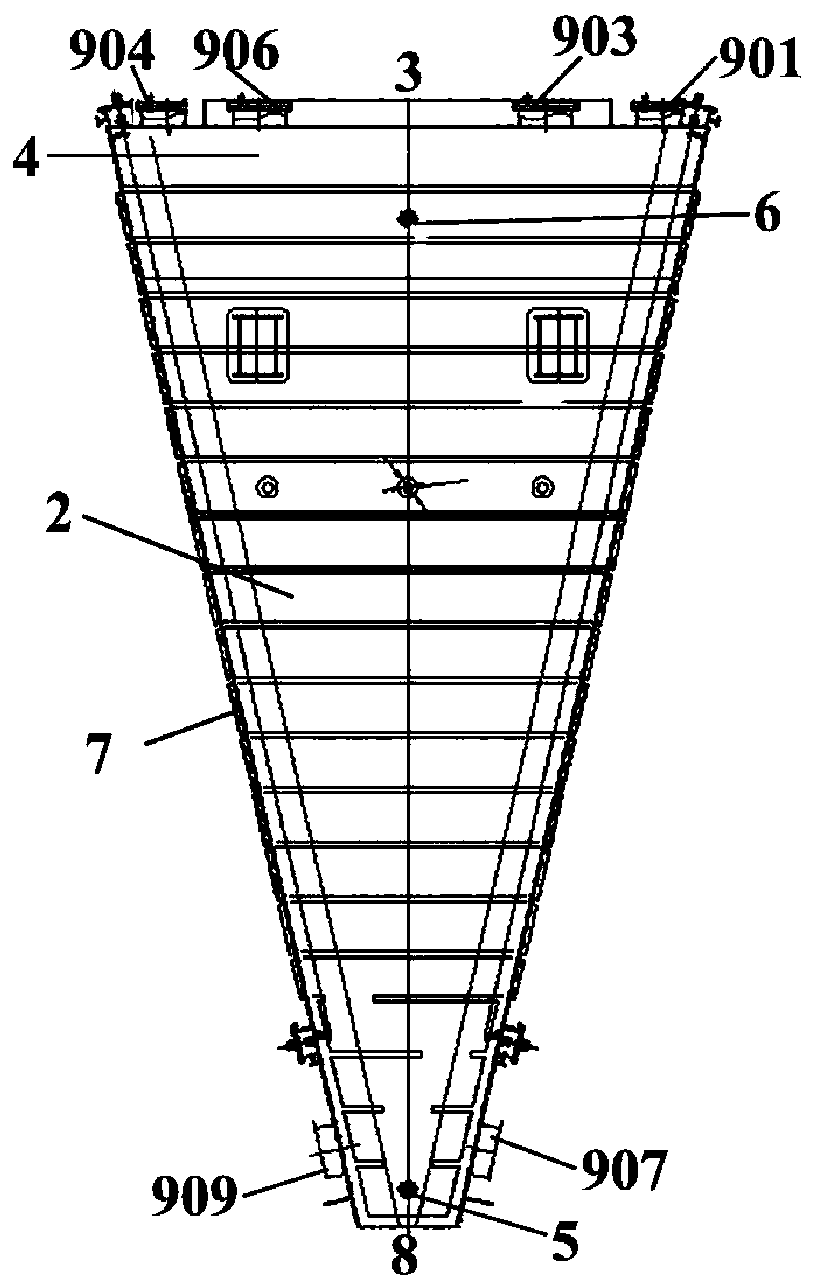

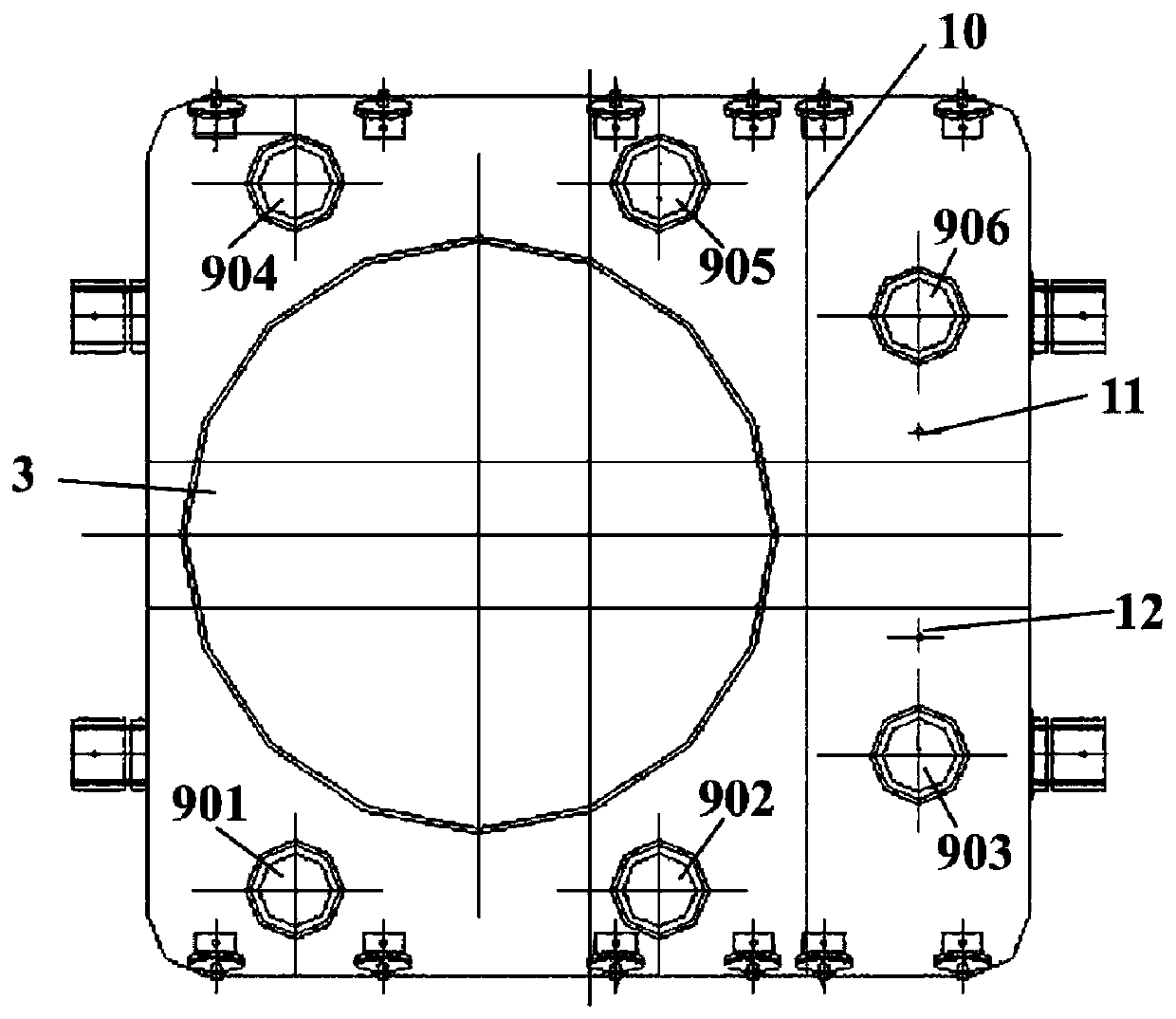

[0071] This embodiment provides a kind of isophthalonitrile dry trapping device, such as Figure 1~3 As shown, the device includes a catcher main body, and the four sides of the catcher main body are composed of two sets of opposite faces, wherein the first set of opposite faces are symmetrically arranged inverted isosceles trapezoidal faces 2, and the second set of opposite faces The face of is rectangular face 1. The inclination angle of the inverted isosceles trapezoidal surface 2 in the main body of the trap is 78°.

[0072] The top of the trap main body is provided with an isophthalonitrile synthesis gas inlet 3 and distributed cleaning manholes 901-906, and on both sides of the isophthalonitrile synthesis gas inlet 3 on the top of the trap main body are provided Temperature measuring port 10 and pressure measuring port 12. An exhaust gas outlet 4 is arranged at the upper position of the isosceles trapezoidal surface 2 of the trap; a steam condensate outlet 5 is arrange...

Embodiment 2

[0082] This embodiment provides a dry isophthalonitrile trapping device, which is the same as that in Embodiment 1 except that the inclination angle of the inverted isosceles trapezoid is 60°. Specifically, the heat exchange area of the trapping device is 200m 2 , volume is 240m 3 , The height of the whole device is 11000mm.

[0083] The isophthalonitrile dry capture device provided in this example captures the same method as in Example 1.

Embodiment 3

[0085] This embodiment provides a dry-process capture device for isophthalonitrile, which is the same as that in Embodiment 1 except that the inclination angle of the inverted isosceles trapezoidal surface is 85°. Specifically, the heat exchange area of the capture device is 240m 2 , volume is 280m 3 , The height of the whole device is 11000mm.

[0086] The isophthalonitrile dry capture device provided in this example captures the same method as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com