A kind of biodegradable bio-based 2,5-furandicarboxylic acid-based copolyester and its preparation method and application

A technology of furandicarboxylic acid-based copolyester and furandicarboxylic acid, which is applied in the manufacture of one-component copolyester rayon, one-component polyester rayon, and rayon, and can solve the problem of low degradability , slow crystallization rate, poor mechanical properties, etc., to achieve good mechanical properties, speed up crystallization speed, and improve color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

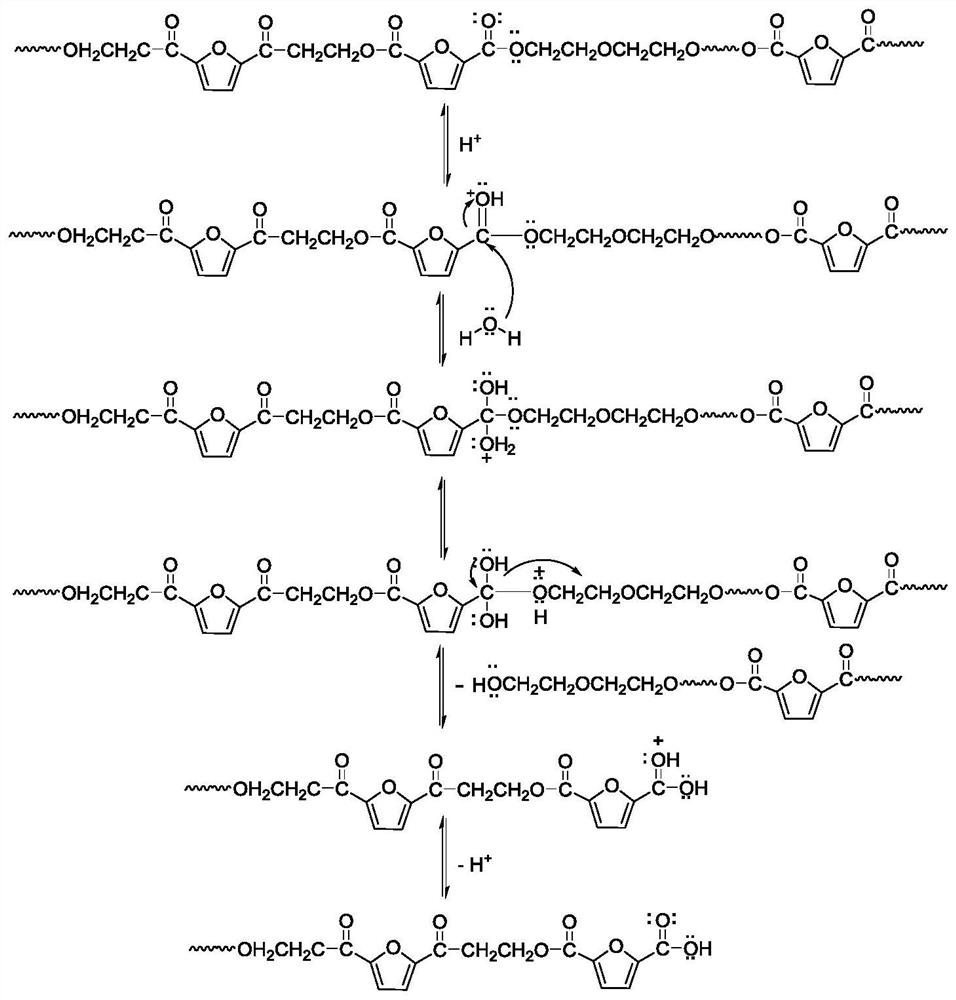

Method used

Image

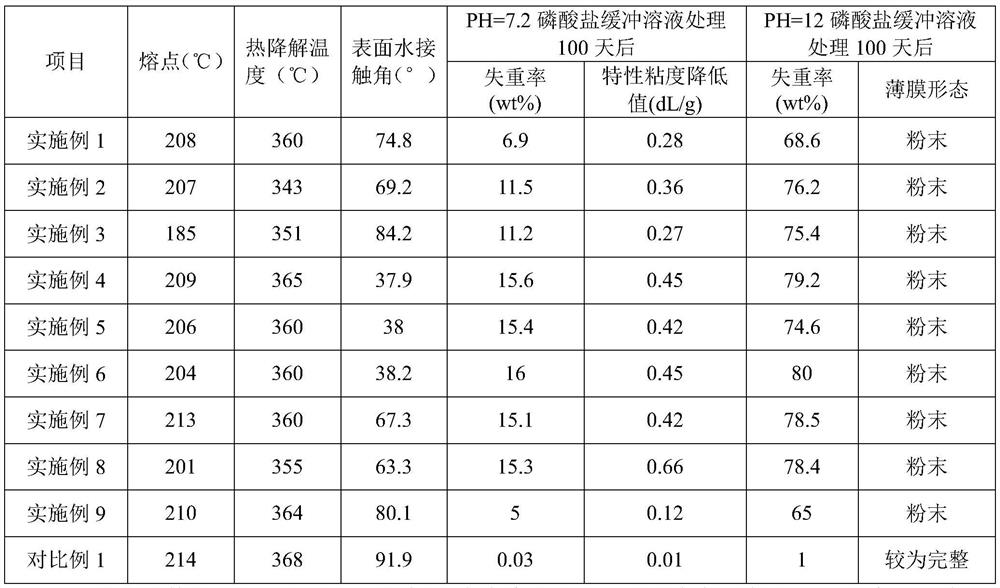

Examples

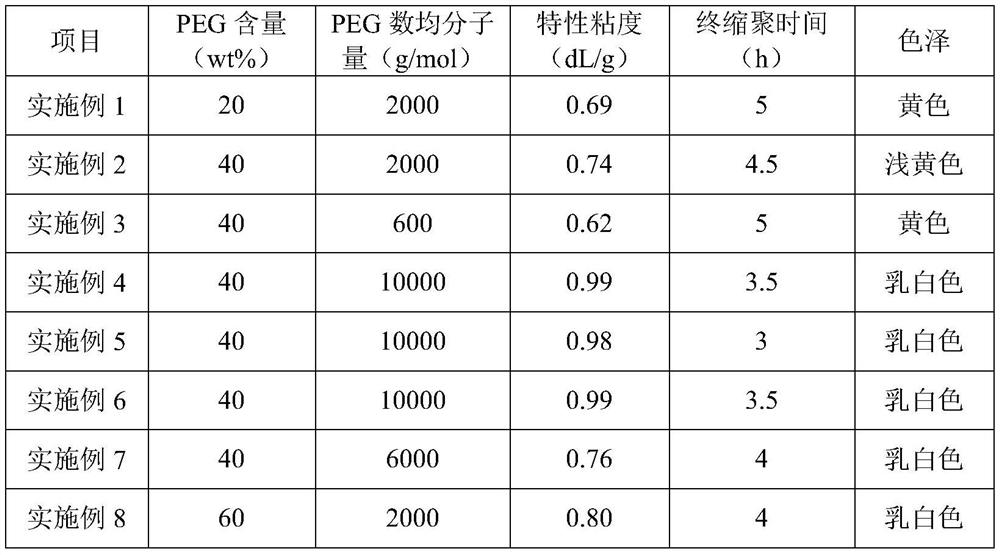

Embodiment 1

[0044] Embodiment 1: A kind of preparation method of biodegradable bio-based 2,5-furandicarboxylate copolyester comprises the following preparation steps:

[0045] 1) Esterification reaction:

[0046] Mix 2,5-furandicarboxylic acid and ethylene glycol at a molar ratio of 1:1.6, then add 0.1mol% tetrabutyl titanate, 0.0015wt% phosphoric acid and 0.003wt% Antioxidant 1010, then carry out esterification reaction at 180°C and 150kPa, until the content of distilled small molecules reaches more than 95% of the theoretical value, the reaction is terminated to obtain an esterification liquid;

[0047] 2) Precondensation reaction:

[0048] Add polyethylene glycol with a number average molecular weight of 2000g / mol and a content of 20wt% relative to 2,5-furandicarboxylic acid to the esterification solution and stir evenly, then raise the temperature to 235°C and control the pressure between 100-1000Pa Precondensation reaction obtains prepolymer;

[0049] 3) Final polycondensation rea...

Embodiment 2

[0051] Embodiment 2: A kind of preparation method of degradable bio-based 2,5-furandicarboxylic acid-based copolyester comprises the following preparation steps:

[0052] 1) Esterification reaction:

[0053] Mix 2,5-furandicarboxylic acid and ethylene glycol uniformly at a molar ratio of 1:1.4, then add a titanium-antimony composite catalyst with a content of 0.15mol% relative to 2,5-furandicarboxylic acid, 0.001wt% triphenyl phosphate and 0.005wt% antioxidant 618, the titanium-antimony composite catalyst is obtained by compounding titanium-silicon composite catalyst and ethylene glycol antimony with a mass ratio of 0.3:0.7; then carry out esterification reaction at 230°C and 50kPa until distillation When the content of the small molecules produced reaches more than 95% of the theoretical value, the reaction is terminated to obtain an esterification liquid;

[0054] 2) Precondensation reaction:

[0055] Add polyethylene glycol with a number average molecular weight of 2000g / ...

Embodiment 3

[0058] Embodiment 3: A kind of preparation method of degradable bio-based 2,5-furandicarboxylic acid-based copolyester comprises the following preparation steps:

[0059] 1) Esterification reaction:

[0060] Mix 2,5-furandicarboxylic acid and ethylene glycol at a molar ratio of 1:2, then add a titanium-antimony composite catalyst with a content of 0.25mol% relative to 2,5-furandicarboxylic acid, 0.002wt% polyphosphoric acid and 0.005 wt% antioxidant 1010, the titanium-antimony composite catalyst is obtained by compounding titanium ethylene glycol and antimony trioxide at a mass ratio of 0.6:0.4; then esterification is carried out at 190°C and 200kPa until the distilled When the content of small molecules reaches more than 95% of the theoretical value, the reaction is terminated to obtain an esterification liquid;

[0061] 2) Precondensation reaction:

[0062] Add polyethylene glycol with a number average molecular weight of 600g / mol and a content of 40wt% relative to 2,5-fur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com