Implantable bandage for promoting bone injury repair and preparation method thereof

A bone injury repair and bandage technology, applied in the field of biomedical implant materials, can solve problems such as the adverse effects of bone injury, endanger the healing efficiency of bone injury, and the lack of periosteum-derived stem cells, so as to avoid soft tissue ingrowth and isolation, and solve bone injury Delayed healing repair, improved biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

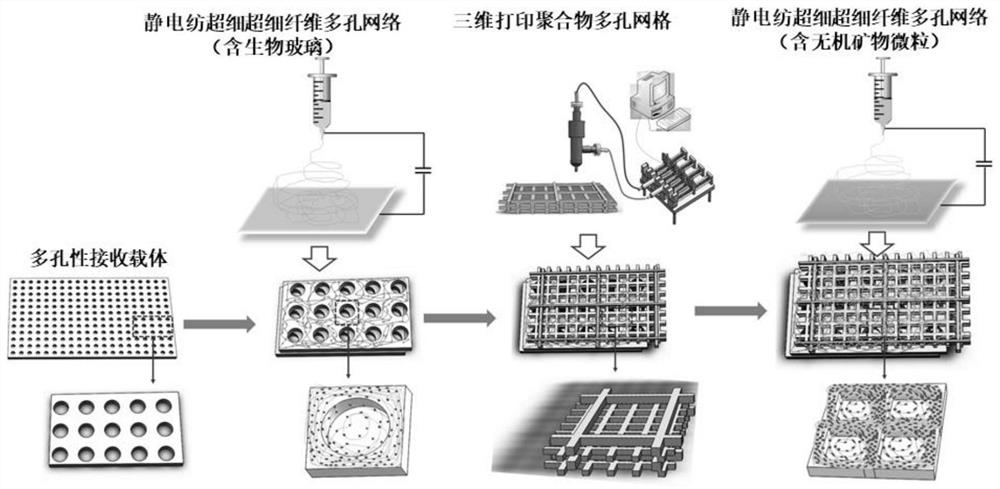

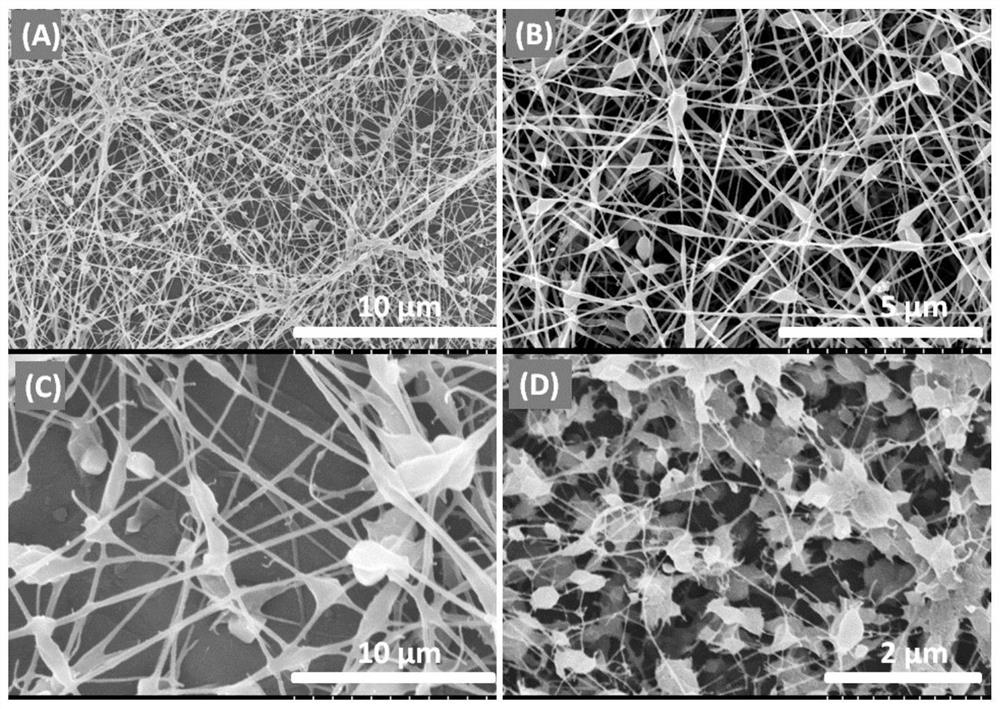

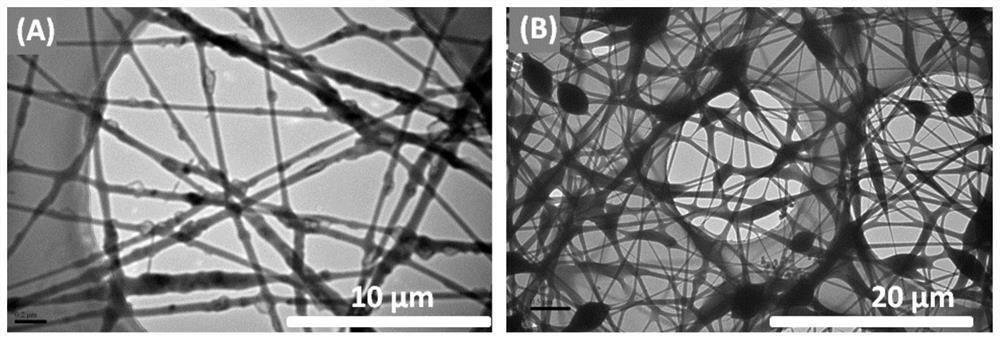

[0094] Example 1: 0.04-8 μm, the particle size of the inorganic mineral particles is 0.02-40 μm.

[0095] 1) Mesoporous bioglass nanopowder with a particle size of 0.15-0.85 μm (chemical composition 28CaO-42SiO 2 -12B 2 o 3 -4P 2 o 5 -6MgO-1CuO-2ZnO-4Na 2 O-1K 2 O) join in the hyaluronic acid-gelatin composite aqueous solution that the mass ratio is 1:9 and stir evenly, the mass ratio of bioglass and organic matter is 1:20, be mixed with the organic-inorganic compound that bioglass concentration is 50mg / ml The solution is then transferred to the electrospinning liquid reservoir, the spinning distance is set to be 15cm, the spinning voltage is 16kV, and the electrospinning is carried out at a speed of 0.4 ml / hour, and then collected on a porous copper foil carrier with a thickness of 200 Micron level microfiber porous film;

[0096] 2) The organic matter used to prepare the poly L-lactide-caprolactone porous grid is directly placed in the material container of the three-...

Embodiment 2

[0100] 1) Mesoporous biological glass particles with a particle size of 0.50-1.20 μm (chemical composition 24CaO-48SiO 2 -12B 2 o 3 -2P 2 o 5 -6MgO-4ZnO-4Na 2 O) join in the sodium alginate-gelatin composite solution that the mass ratio is 2:5 and stir evenly, the mass ratio of superfine particle and organic matter is 1:15, is mixed with the organic-inorganic that superfine particle concentration is 20mg / ml The complex solution is then transferred to the electrospinning liquid reservoir, the spinning distance is set to 18cm, the spinning voltage is 18kV, and the electrospinning is carried out at a speed of 0.3 ml / hour, and then collected on an aluminum foil carrier with a thickness of 150 Micron level microfiber porous film;

[0101] 2) The organic matter used to prepare the polycaprolactone porous grid is directly placed in the material container of the three-dimensional printer, and the polymer is softened by heating and extruded out of the printing nozzle. The ultrafin...

Embodiment 3

[0105] 1) Mesoporous biological glass powder (24CaO-56SiO 2 -8B 2 o 3 -4MgO-2ZnO-6Na 2 O) join in the sodium alginate-gelatin-polyvinyl phosphate compound organic matter solution that the mass ratio is 2:8:1 and stir evenly, the mass ratio of superfine particle and organic matter is 1:15, is mixed with superfine particle concentration: The organic-inorganic composite solution of 20mg / ml is then transferred to the liquid reservoir of electrospinning, the spinning distance is set to be 16cm, the spinning voltage is 20kV, and the electrospinning is carried out at a speed of 0.4 ml / hour, and then Collect the superfine fiber porous film with a thickness of 280 microns on the aluminum foil drum carrier;

[0106] 2) The organic matter used to prepare the porous sodium carboxymethyl cellulose grid is directly placed in the material container of the three-dimensional printer, and the polymer is softened by heating and extruded out of the printing nozzle, so that the ultrafine fibers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com