A kind of mesoporous bioglass/polyglyceryl sebacate composite scaffold and its preparation method and application

A technology of polyglycerol sebacate and polyglycerol sebacate, which is applied in the fields of material science and medicine, can solve the problems of limited application, promote cell adhesion and proliferation, improve bone repair ability and new bone growth ability, Achieving the effect of complete regeneration/repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] The preparation method of composite support comprises the following steps:

[0054] (a) Coating PGS on the MBG porous scaffold;

[0055] (b) The scaffold is freeze-dried to obtain a composite scaffold.

[0056] Preferably, the mesoporous bioglass scaffold matrix is prepared by a sol-gel method combined with a PU sponge template method. In a preferred embodiment, after uniformly mixing 100 parts by weight of MBG sol and 1 to 10 parts by weight of MBG powder, the mixture is mixed at 0.4 to 0.9 g / cm 3 The mass-to-volume ratio is poured on PU sponge, aged, dried, and calcined to obtain MBG porous scaffold, that is, the mesoporous bioglass scaffold matrix. In a preferred embodiment, with TEOS (orthoethyl silicate), Ca (NO 3 )·4H 2 O. TEP (triethyl phosphate) is the raw material, and F127 is the mesoporous template agent. Add 1-15 parts by weight of the mesoporous template agent into ethanol, adjust the pH to less than 2 with hydrochloric acid, and add four 0.3-5 parts...

Embodiment 1

[0086] Preparation of MBG sols and powders

[0087] 8g polyoxyethylene / polyoxypropylene / polyoxyethylene amphiphilic block copolymer ( F127, referred to as F127) and 6ml 1M HCl were added to 100g ethanol, and after complete dissolution, 1.52g Ca(NO 3 )·4H 2 O (calcium nitrate tetrahydrate) and 0.43ml TEP (triethyl phosphate), after completely dissolved, add 10.4g TEOS (tetraethyl orthosilicate) dropwise, stir vigorously at 40°C for 24 hours, and evaporate the obtained solution to a viscosity of 60°C 5×10 4 MPa to get MBG sol.

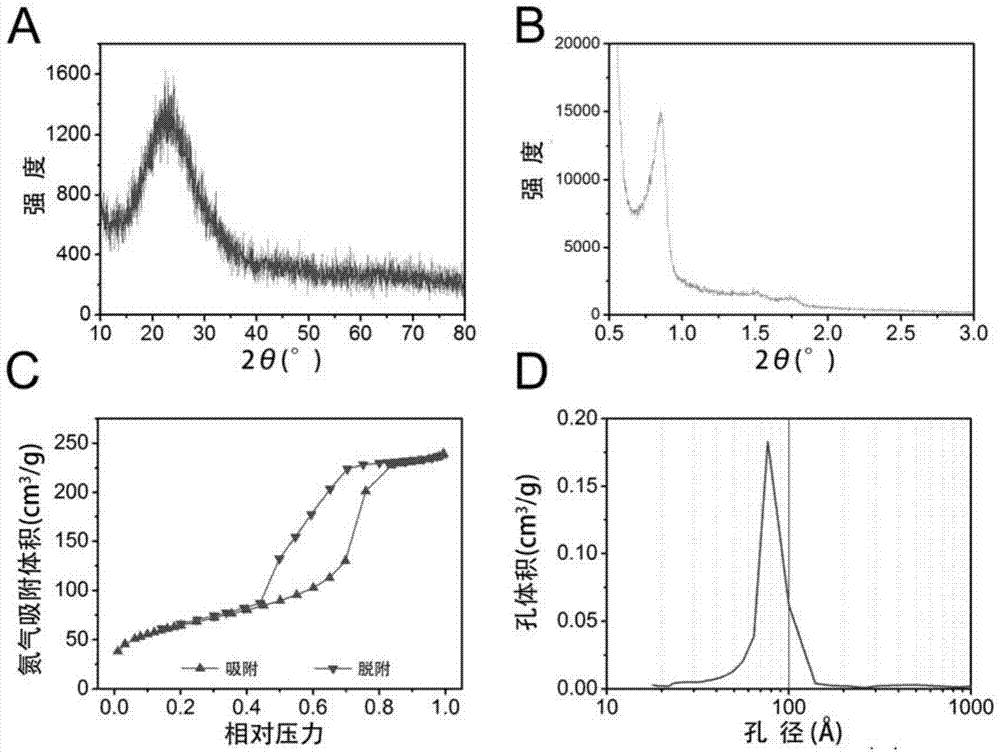

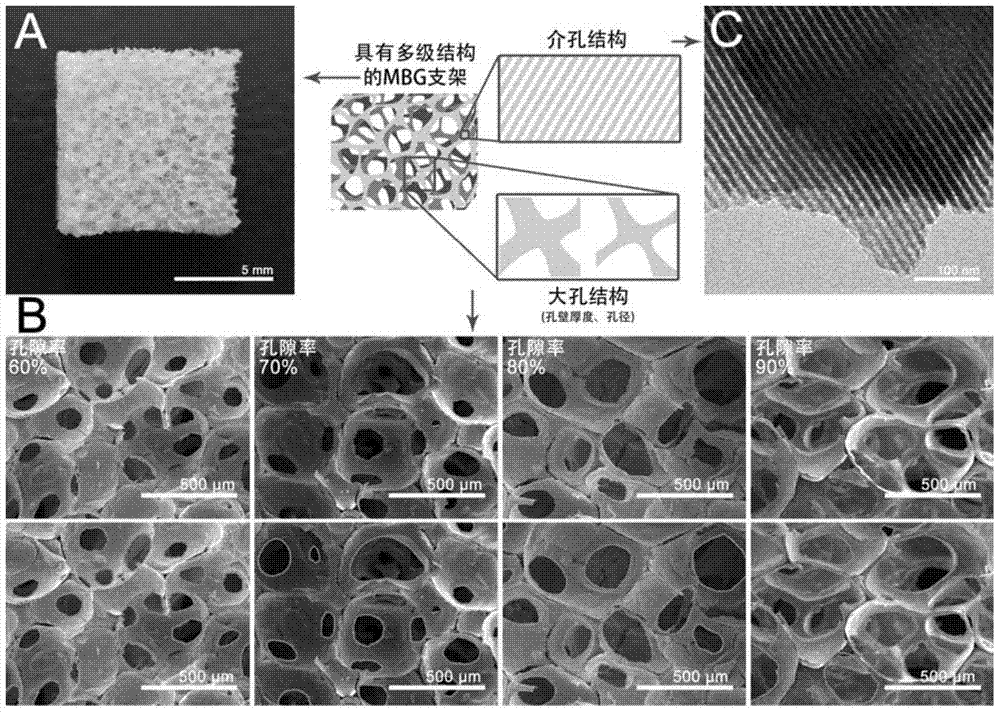

[0088] Dry the prepared sol (60°C, 72 hours), grind it into powder with a mortar, and perform high-temperature calcination according to the following heating program: 20°C~600°C (580min, 1°C / min), 600°C~600°C (360min), end. Obtained MBG powder, wide-angle XRD pattern (A) and small-angle XRD pattern (B), nitrogen adsorption-desorption curve (C) and mesopore size distribution pattern (D) are as figure 1 As shown, the transmission electron microscop...

Embodiment 2

[0090] Preparation of MBG scaffold with 60% porosity (60%MBG)

[0091] The MBG sol and MBG powder prepared in Example 1 were uniformly mixed in a ratio of 6g / 0.1g, and mixed at a rate of 0.857g / cm 3 The mass-to-volume ratio is poured on the pre-cut polyurethane PU sponge, aged at room temperature for 24 hours, dried at 60°C for 72 hours, and high-temperature calcined according to the following heating program: 20°C~600°C (580min, 1°C / min), 600°C ℃~600℃(360min), end. MBG scaffolds with a porosity of 60% are available (labeled 60% MBG).

[0092] The overall morphology of the obtained 60% MBG scaffold is as follows figure 2 As shown in A, the scanning electron microscope (SEM) photos taken by the macroporous structure are as follows: figure 2 As shown in the first column of B, the observed outline of the macropore structure in the outer layer is marked with a green line, and the measured average macropore diameter is 113.1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com