A kind of bacterial cellulose/graphene/ferric oxide composite film and preparation method thereof

A bacterial cellulose membrane and bacterial cellulose technology are applied in the field of bacterial cellulose/graphene/iron tetroxide composite membrane and its preparation, which can solve the problem that bacterial cellulose and graphene oxide are difficult to mix evenly, and the concentration of lyotropic liquid crystals It is not easy to control, the conductive polymer is easy to fall off, etc., to achieve the effect of adjustability, mechanical strength, and stable electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

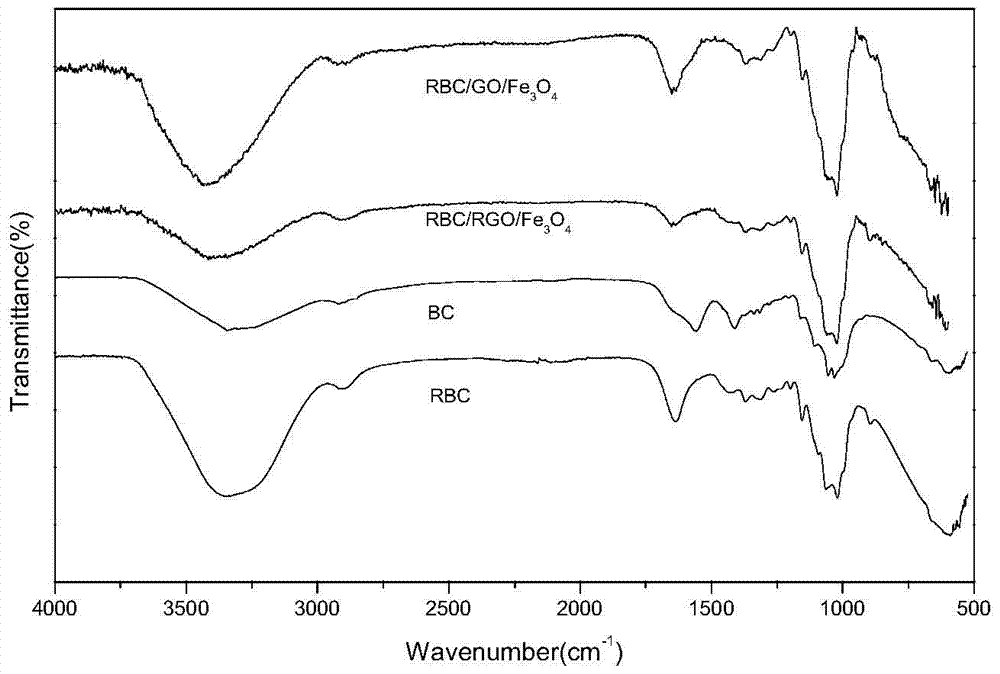

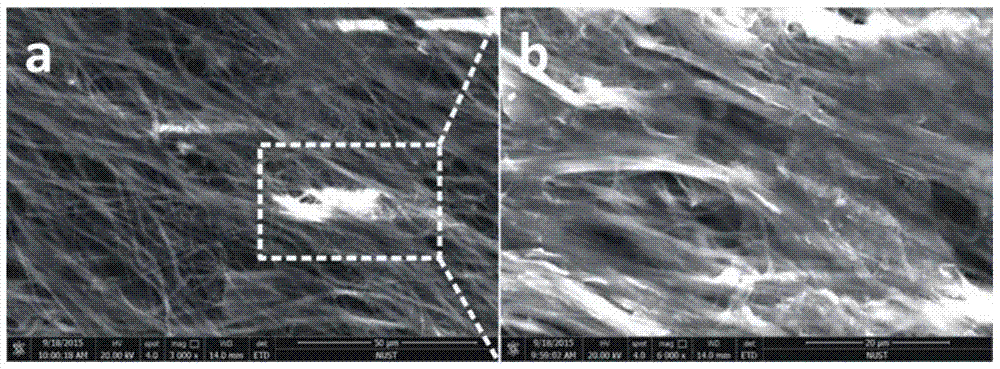

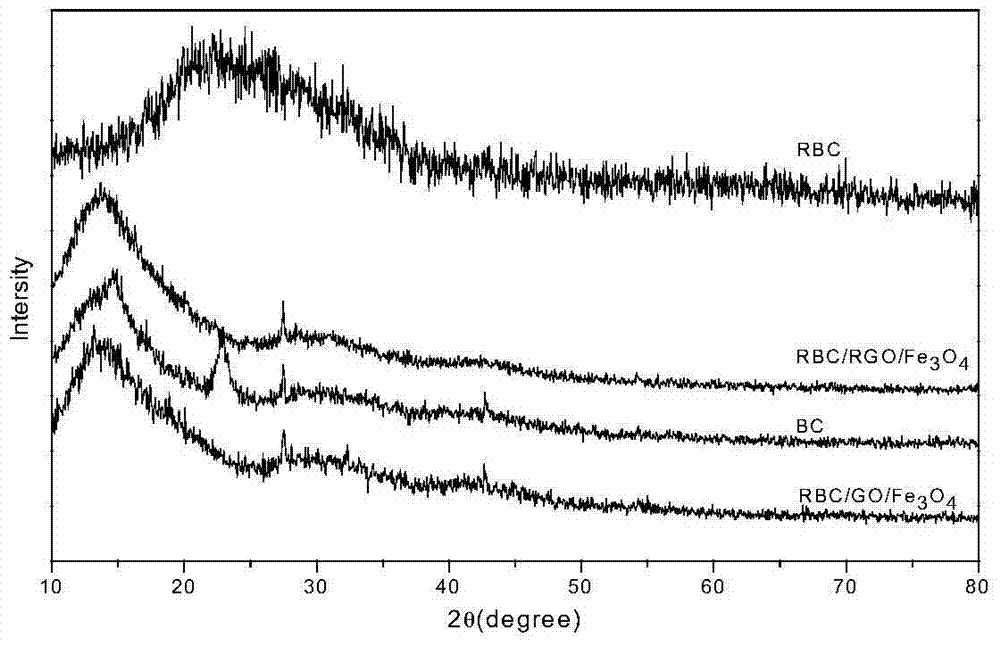

[0030] The pure bacterial cellulose film was vacuum-dried at room temperature for 12h to prepare bacterial cellulose airgel, and the airgel was ground into powder, and then the bacterial cellulose powder was dispersed in LiCl with an amount of 4% (w / v) In the DMAc / LiCl mixed solvent, a clear bacterial cellulose solution with a mass concentration of 2% was obtained through freezing, thawing and heating. The freezing temperature is -10°C, the thawing temperature is room temperature, and the heating temperature is 80°C. Weigh 10% graphene oxide with a mass of bacterial cellulose powder and iron ferric oxide nanoparticles with a mass of 40% bacterial cellulose powder, and uniformly disperse them in N,N-dimethylformaldehyde with the same volume as the bacterial cellulose solution In base acetamide, then mixed with a clarified bacterial cellulose solution, after ultrasonic degassing for 15min, a clarified bacterial cellulose / graphene oxide / ferric oxide mixed solution was obtained, a...

Embodiment 2

[0033]The pure cellulose film was vacuum-dried at room temperature for 12h to prepare bacterial cellulose airgel, and the airgel was ground into powder, and then the bacterial cellulose powder was uniformly dispersed in LiCl with an amount of 8% (w / v ) in the DMAc / LiCl mixed solvent, through freezing, thawing and heating to obtain a clear bacterial cellulose solution with a mass concentration of 2%. The freezing temperature is -5°C, the thawing temperature is room temperature, and the heating temperature is 80°C. Weigh 20% graphene oxide with a mass of bacterial cellulose powder and iron ferric oxide nanoparticles with a mass of 40% bacterial cellulose powder, and uniformly disperse them in N,N-dimethylformaldehyde with the same volume as the bacterial cellulose solution In base acetamide, then mixed with clarified bacterial cellulose solution, ultrasonically degassed for 15 minutes to obtain a clarified bacterial cellulose / graphene oxide mixed solution, and then used an elect...

Embodiment 3

[0036] The pure cellulose film was vacuum-dried at room temperature for 12h to prepare bacterial cellulose airgel, and the airgel was ground into powder, and then the bacterial cellulose powder was uniformly dispersed in LiCl with an amount of 8% (w / v ) in the DMAc / LiCl mixed solvent, through freezing, thawing and heating to obtain a clear bacterial cellulose solution with a mass concentration of 2%. The freezing temperature is -5°C, the thawing temperature is room temperature, and the heating temperature is 80°C. Weigh 30% graphene oxide with a mass of bacterial cellulose powder and iron ferric oxide nanoparticles with a mass of 50% of bacterial cellulose powder, and uniformly disperse them in N,N-dimethylformamide with the same volume as bacterial cellulose solution. In base acetamide, then mixed with clarified bacterial cellulose solution, ultrasonically degassed for 15 minutes to obtain a clarified bacterial cellulose / graphene oxide mixed solution, and then used an electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com