Method for removing heavy metals in sludge

A technology for heavy metals and sludge, applied in sludge treatment, biological sludge treatment, chemical instruments and methods, etc., can solve the problem of low removal efficiency of heavy metals, and achieve the goal of facilitating the migration of heavy metals, strong reproductive capacity, and reducing the amount of precipitation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A method for removing heavy metals in sludge, such as figure 1 shown, including the following steps:

[0050] 1. Sludge acidification pretreatment: crush the industrial sludge with a heavy metal Cd content of 544.61mg / kg, add deionized water according to the mass ratio of deionized water to sludge dry matter 3:1, stir evenly, and then add to the sludge Add a certain amount of dilute nitric acid to adjust the pH of the sludge to 6, and balance for 8 hours.

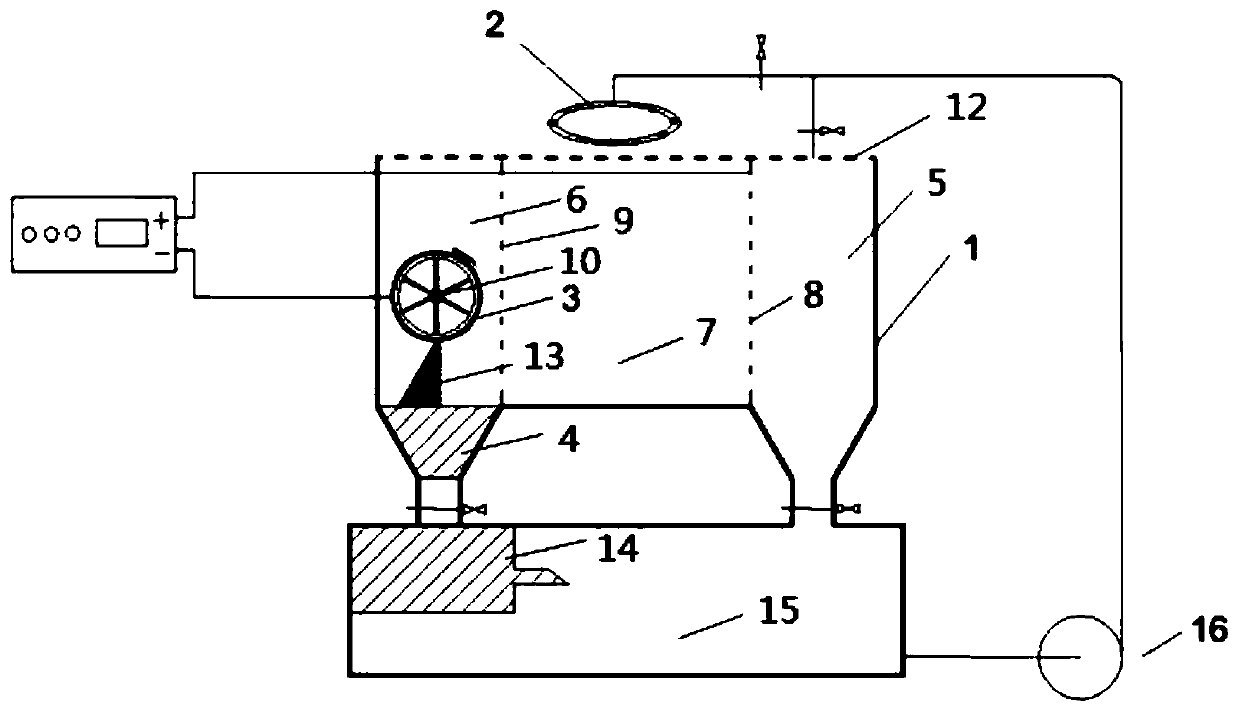

[0051] 2. Electric-leaching repair: Assemble the electrolysis device, such as figure 2 As shown, the electrolysis device includes an anode chamber 5, a cathode chamber 6 and a sludge chamber 7; the anode chamber 5 and the sludge chamber 7 are separated by an anode plate 8, and the surface of the anode plate 8 has a hole structure; the cathode The chamber 6 and the sludge chamber 7 are separated by a partition 9, and the surface of the partition 9 has a hole structure; the cathode 3 is located in the cathode chambe...

Embodiment 2

[0057] 1. Sludge acidification pretreatment: crush the industrial sludge with a heavy metal Cu content of 3504.63mg / kg, add deionized water according to the mass ratio of deionized water to sludge dry matter 3:1, stir evenly, and then add to the sludge Add a certain amount of dilute nitric acid to adjust the pH of the sludge to about 5, and balance for 8 hours.

[0058] 2. Electric-leaching repair: use the electric washing device in Example 1 to treat for 6 hours and then cut off the power, use the Tessier five-step extraction method to measure the form of heavy metals in the treated sludge, and the measured Cu residue state is changed from the initial 782.41mg / kg decreased to 250.03mg / kg, while the carbonate binding state increased from 530.56mg / kg to 1031.22mg / kg.

[0059] 3. Bioremediation: Mix the sludge obtained in step 2 with ordinary soil at a mass ratio of 2:3, apply an appropriate amount of water, and plant an appropriate amount of bermudagrass seedlings. After the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com