Polymer anti-crack mortar

An anti-cracking mortar and polymer technology, applied in the field of construction mortar, can solve the problems of poor dispersion, easy agglomeration, and affecting durability, so as to improve crack resistance, comprehensive performance, compressive strength and flexural strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

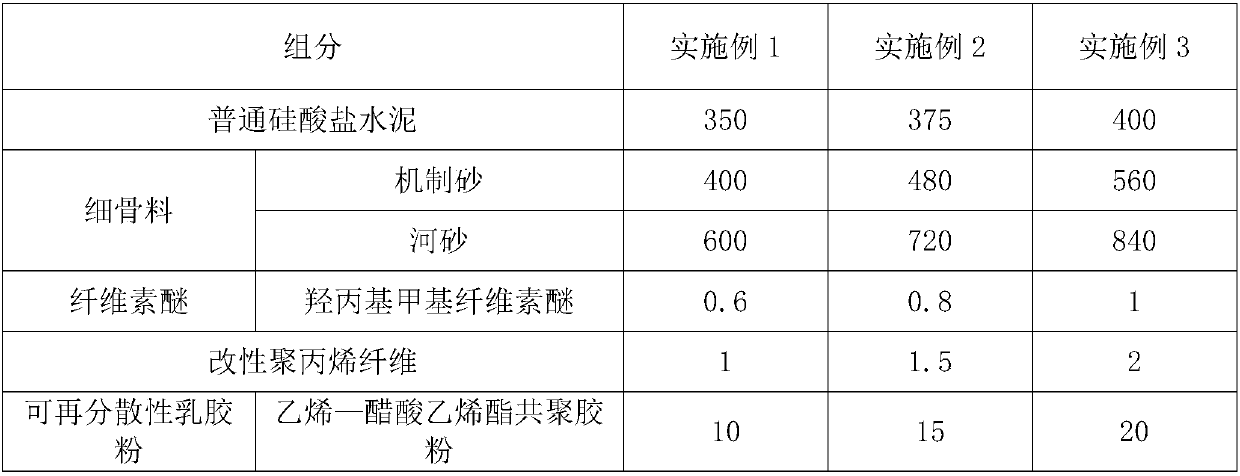

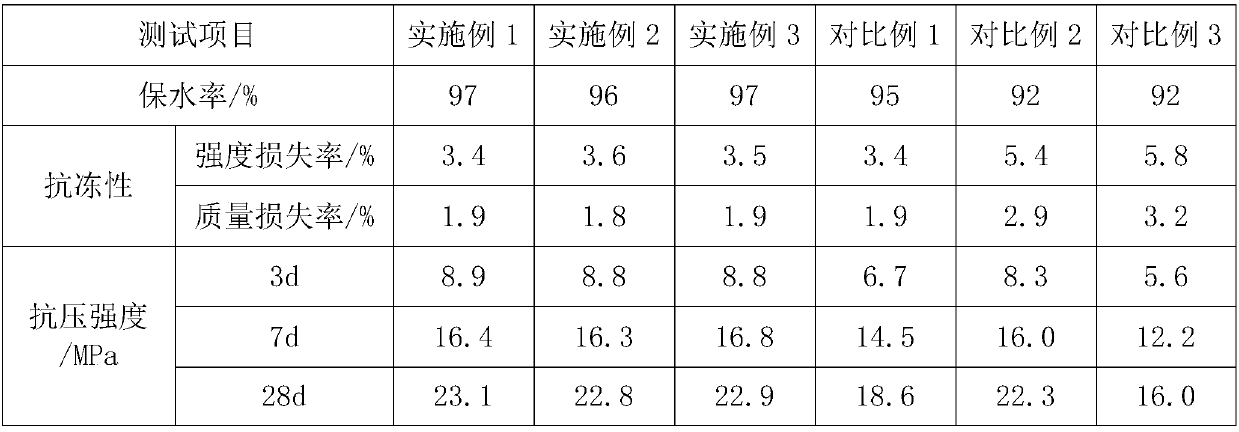

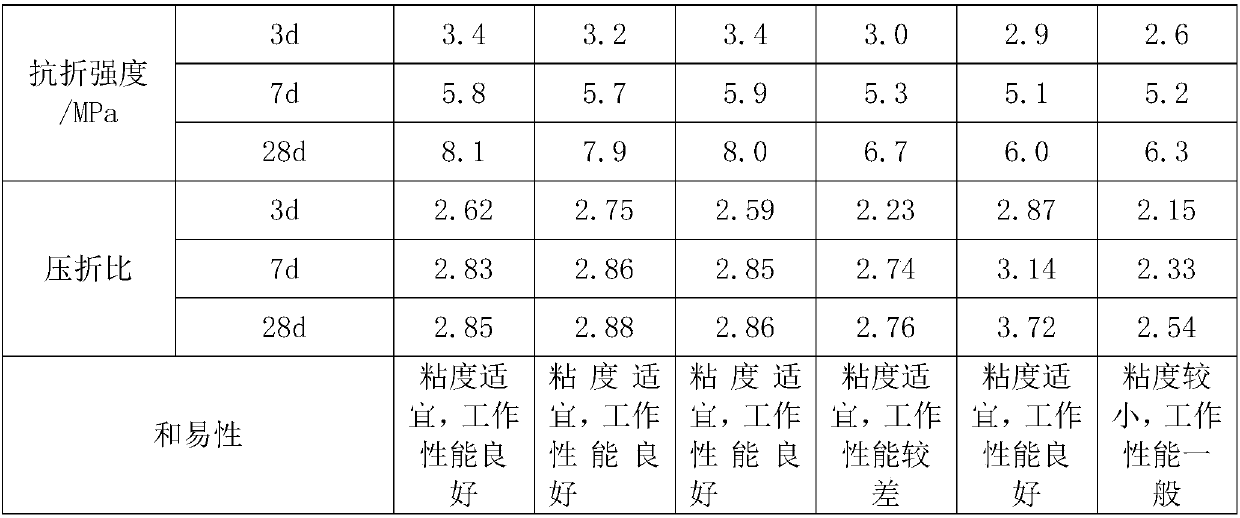

Method used

Image

Examples

preparation example 1

[0038] ①Pretreatment: Immerse 2kg of polypropylene fibers with a length of 3mm in 5kg and 1wt% sodium hypochlorite solution for 30s at a temperature of 60°C; then immerse the polypropylene fibers in 20kg of N with a weight ratio of 1:3, Soak in the mixture of N-dimethylacrylamide and acetone for 10 minutes;

[0039] ②Chemical modification: Add 0.6kg of aminopropyltrimethoxysilane and 0.4kg of diacetone acrylamide to 30kg, 70wt% ethanol solution, heat up to 40°C, stir for 10min, and then add poly For acrylic fibers, stir for 1 hour at a temperature of 40°C, then stop heating, let it cool to room temperature and continue soaking for 16 hours;

[0040]③Washing and drying: Take out the polypropylene fiber treated in step ②, wash it with 10wt% ethanol solution for 5min, the flow rate of the ethanol solution is 20mL / min, and place the washed polypropylene fiber at a temperature of 90°C , After drying for 4 hours, the modified polypropylene fiber was obtained.

preparation example 2

[0042] ①Pretreatment: Immerse 2kg of polypropylene fibers with a length of 6mm in 6kg of 1.5wt% sodium hypochlorite solution for 35s at a temperature of 65°C; then immerse the polypropylene fibers in 24kg of N with a weight ratio of 1:3 , soaked in a mixture of N-dimethylacrylamide and acetone for 15 minutes;

[0043] ②Chemical modification: Add 0.7kg of aminopropyltrimethoxysilane and 0.5kg of diacetone acrylamide to 35kg of 80wt% ethanol solution, heat up to 45°C, stir for 15min, then add poly Propylene fiber, at a temperature of 45°C, stir for 1.5h, then stop heating, let it cool to room temperature and continue soaking for 17h;

[0044] ③Washing and drying: Take out the polypropylene fiber treated in step ②, rinse it with 30wt% ethanol solution for 7.5min, the flow rate of the ethanol solution is 25mL / min, and place the washed polypropylene fiber at a temperature of 95°C After drying for 5 hours, modified polypropylene fibers were obtained.

preparation example 3

[0046] ①Pretreatment: Immerse 2kg of polypropylene fibers with a length of 9mm in 7kg and 2wt% sodium hypochlorite solution for 40s at a temperature of 70°C; then immerse the polypropylene fibers in 28kg of N with a weight ratio of 1:3, Soak in a mixture of N-dimethylacrylamide and acetone for 20 minutes;

[0047] ②Chemical modification: Add 0.8 kg of aminopropyltrimethoxysilane and 0.6 kg of diacetone acrylamide to 40 kg of 90 wt % ethanol solution, heat up to 50 ° C, stir for 20 min, and then add poly Propylene fibers, at a temperature of 50 ° C, stirred for 2 hours, then stopped heating, allowed to cool to room temperature and continued to soak for 18 hours;

[0048] ③Washing and drying: Take out the polypropylene fiber treated in step ②, wash it with 50wt% ethanol solution for 10min, the flow rate of the ethanol solution is 30mL / min, and place the washed polypropylene fiber at a temperature of 100°C , After drying for 6 hours, the modified polypropylene fiber was obtained...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com