Steel slag concrete with steel slag replacing broken stone and preparation method thereof

A technology of steel slag concrete and ordinary concrete, which is applied in the field of concrete preparation, can solve the problems of difficulty in meeting use requirements, water absorption, large shrinkage rate, etc., and achieves the effects of reducing expansion and shrinkage, simple process and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

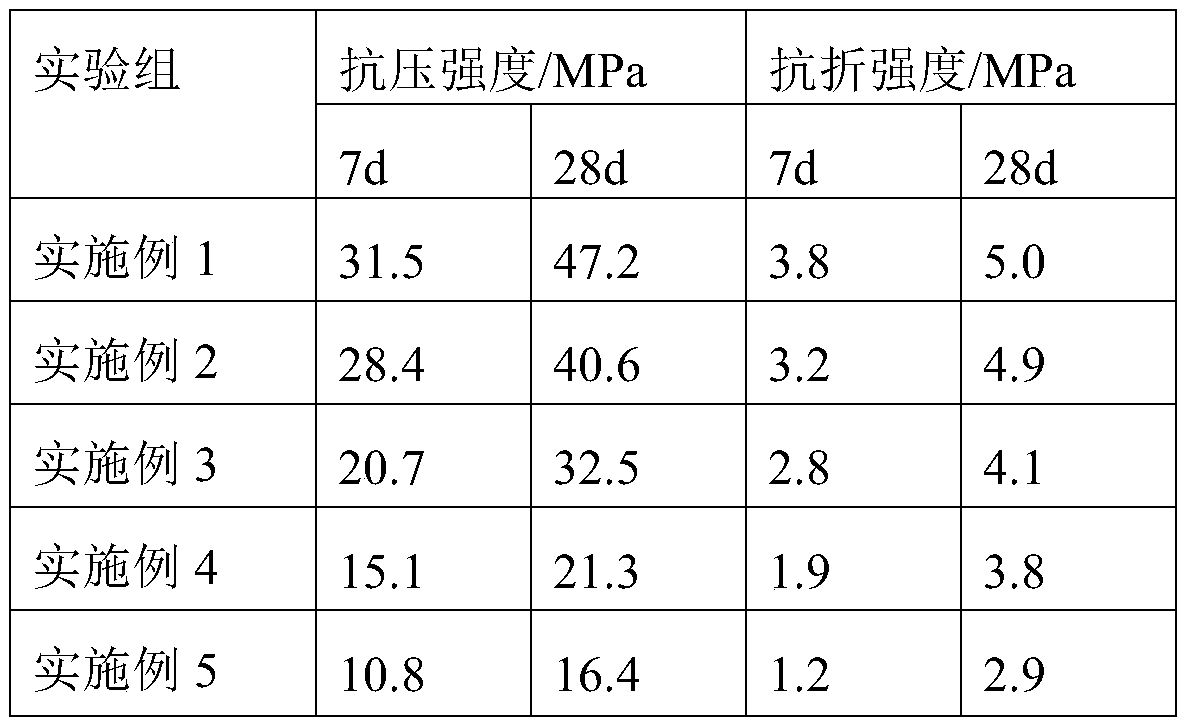

Examples

Embodiment 1

[0015] A kind of steel slag concrete in which steel slag replaces gravel, the steel slag concrete label is C30, and its preparation method is as follows:

[0016] S101, pulverizing the steel slag after hot stewing to obtain coarse aggregate; taking 30kg of steel slag with a particle size of 5-15mm and 120kg of steel slag with a particle size of 5-25mm;

[0017] S102. Take 50kg of medium sand that meets the requirements of ordinary concrete preparation;

[0018] S103, take 24kg of 42.5 cement, 3kg of grade II fly ash, 8kg of S95 grade mineral powder, and 0.7kg of polycarboxylate superplasticizer;

[0019] S104, uniformly mixing steel slag, cement, fly ash, mineral powder, sand, and polycarboxylate water reducer to obtain steel slag concrete;

[0020] S105, curing the steel slag concrete.

Embodiment 2

[0022] A kind of steel slag concrete in which steel slag replaces gravel, the steel slag concrete label is C25, and its preparation method is as follows:

[0023] S101, pulverizing the steel slag after hot stewing to obtain coarse aggregate; taking 30kg of steel slag with a particle size of 5-15mm and 120kg of steel slag with a particle size of 5-25mm;

[0024] S102. Take 53kg of medium sand that meets the requirements of ordinary concrete preparation;

[0025] S103, take 21kg of 42.5 cement, 3kg of grade II fly ash, 8kg of S95 grade mineral powder, and 0.7kg of polycarboxylate superplasticizer;

[0026] S104, uniformly mixing steel slag, cement, fly ash, mineral powder, sand, and polycarboxylate water reducer to obtain steel slag concrete;

[0027] S105, curing the steel slag concrete.

Embodiment 3

[0029] A kind of steel slag concrete in which steel slag replaces gravel, the steel slag concrete label is C20, and its preparation method is as follows:

[0030] S101, pulverizing the steel slag after hot stewing to obtain coarse aggregate; taking 30kg of steel slag with a particle size of 5-15mm and 120kg of steel slag with a particle size of 5-25mm;

[0031] S102, take 56kg of medium sand that meets the requirements of ordinary concrete preparation;

[0032] S103, take 18kg of 42·5 cement, 3kg of grade II fly ash, 8kg of S95 grade mineral powder, and 0.7kg of polycarboxylate superplasticizer;

[0033] S104, uniformly mixing steel slag, cement, fly ash, mineral powder, sand, and polycarboxylate water reducer to obtain steel slag concrete;

[0034] S105, curing the steel slag concrete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com