Preparation method of anti-alumina-electrolysis prebaked anode

A prebaked anode and anti-alumina technology, which is applied in the field of aluminum electrolysis, can solve the problems that affect the production parameters of aluminum electrolytic cells, the stability of production operation, poor anti-air reaction performance and anti-carbon dioxide reaction performance, and fast anode consumption, etc., to achieve Effects of reducing air permeability, improving anti-oxidation ability, and reducing the amount of carbon residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

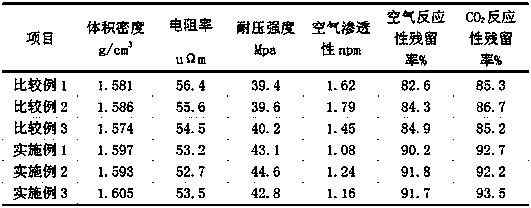

Examples

Embodiment 1

[0021] Example 1, the preparation method of a prebaked anode for anti-alumina electrolysis described in this specific embodiment is characterized in that it includes the following steps: Step S1: after the petroleum coke is calcined at high temperature, the calcined coke obtained is Crushing, sieving and grading to obtain calcined coke aggregates and powders of various particle sizes; step S2: adding the calcined coke aggregates and powders obtained in step S1 into the kneading pot according to the designed ratio, kneading, preheating, and then adding additives, The binder coal tar pitch is continuously heated and kneaded evenly to obtain an anode paste; step S3: the anode paste obtained in step S2 is placed into a vibration molding machine for vibration molding to make an anti-oxidation prebaked anode green body; step S4: S3 After cooling down, the anti-oxidation prebaked anode green body is placed in a roasting furnace for roasting according to the designed heating curve; Ste...

Embodiment 2

[0029] Example 2, the preparation method of a prebaked anode for anti-alumina electrolysis described in this specific embodiment is characterized in that it includes the following steps: Step S1: after the petroleum coke is calcined at high temperature, the calcined coke obtained is Crushing, sieving and grading to obtain calcined coke aggregates and powders of various particle sizes; step S2: adding the calcined coke aggregates and powders obtained in step S1 into the kneading pot according to the designed ratio, kneading, preheating, and then adding additives, The binder coal tar pitch is continuously heated and kneaded evenly to obtain an anode paste; step S3: the anode paste obtained in step S2 is placed into a vibration molding machine for vibration molding to make an anti-oxidation prebaked anode green body; step S4: S3 After cooling down, the anti-oxidation prebaked anode green body is placed in a roasting furnace for roasting according to the designed heating curve; Ste...

Embodiment 3

[0037] Example 3, the preparation method of a prebaked anode for anti-alumina electrolysis described in this specific embodiment is characterized in that it includes the following steps: Step S1: after the petroleum coke is calcined at high temperature, the calcined coke obtained is Crushing, sieving and grading to obtain calcined coke aggregates and powders of various particle sizes; step S2: adding the calcined coke aggregates and powders obtained in step S1 into the kneading pot according to the designed ratio, kneading, preheating, and then adding additives, The binder coal tar pitch is continuously heated and kneaded evenly to obtain an anode paste; step S3: the anode paste obtained in step S2 is placed into a vibration molding machine for vibration molding to make an anti-oxidation prebaked anode green body; step S4: S3 After cooling down, the anti-oxidation prebaked anode green body is placed in a roasting furnace for roasting according to the designed heating curve; Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com