Naked-eye 3D display screen material and preparation method thereof

A display and 3D technology, applied in the field of naked-eye 3D display, can solve the problems of high processing cost, expensive equipment, complicated process, etc., and achieve the effect of good uniformity of light intensity distribution, easy operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

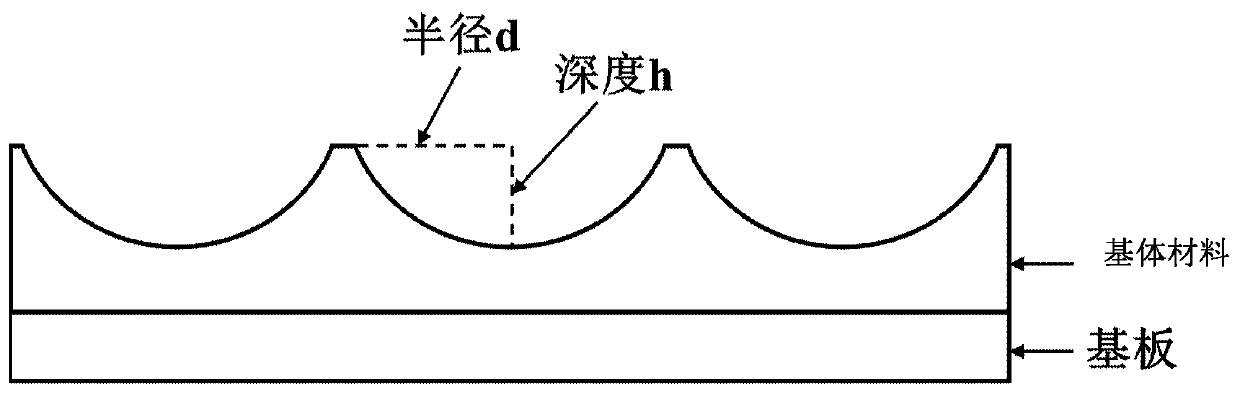

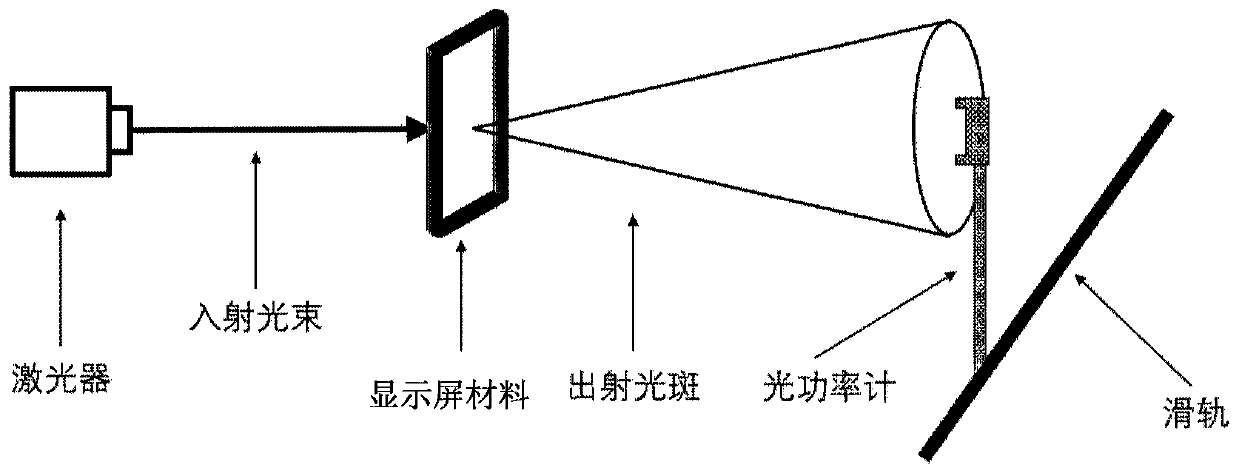

[0022] Specifically, according to some embodiments of the present invention, a method for preparing a naked-eye 3D display material is provided, including the following steps:

[0023] (1) Provide a polymer solution in which a matrix material is dissolved in a volatile solvent, wherein the matrix material is an optically transparent material, and the volatile solvent is immiscible with water.

[0024] Preferably, the naked-eye 3D display material adopts an optically transparent homopolymer or copolymer as a matrix material, such as polystyrene-butadiene-styrene block copolymer (SBS), polycarbonate (PC), polyethylene Imine (PEI), polymethyl methacrylate (PMMA), etc. More preferably, it is SBS, which has the advantages of good film-forming performance, uniform microstructure size of the obtained display screen material, and wide adjustable range. As a further preference, the volatile solvent is one or more of carbon disulfide, methylene chloride, chloroform and toluene.

[002...

Embodiment 1

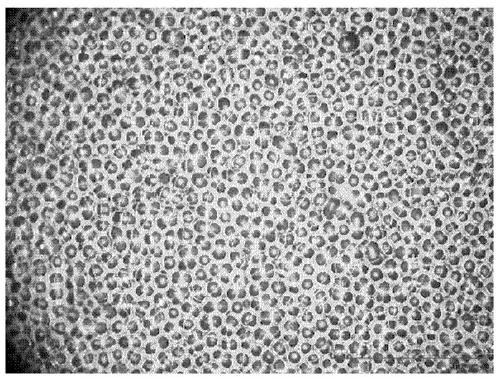

[0043]First select silica glass as the substrate, then weigh a certain amount of polystyrene-butadiene-styrene block copolymer (SBS) and dissolve it in carbon disulfide, configure it into a 0.1g / mL SBS carbon disulfide solution, and then 0.2mL / cm in a closed container at 25°C and 80% relative humidity 2 The aforementioned solution is cast on the surface of the substrate, and the solvent volatilization promotes the nucleation and growth of water droplets on the solution surface, and the naked-eye 3D display material is obtained after the solvent and water droplets are completely volatilized. The size range of the radius d of the spherical pit on the screen surface is 25μm±2μm, and the size range of the depth h is 25μm±2μm. After testing, the light scattering angle of the screen is about 40°, the light transmittance is about 75%, and the light intensity evenly distributed. Such as image 3 Shown is the optical topography of the naked-eye 3D display, and it can be seen that it ...

Embodiment 2

[0045] First select silica glass as the substrate, then weigh a certain amount of polycarbonate (PC) and dissolve it in dichloromethane to form a PC dichloromethane solution of 0.14g / mL, and then place it at 20°C and 90% relative humidity In an airtight container at 0.3mL / cm 2 The aforementioned solution is cast on the surface of the substrate, and the solvent volatilization promotes the nucleation and growth of water droplets on the solution surface, and the naked-eye 3D display material is obtained after the solvent and water droplets are completely volatilized. The size range of the radius d of the spherical pit on the screen surface is 50μm±5μm, the size range of the depth h is 1μm±0.1μm, the light scattering angle of the screen is about 1°, the light transmittance is about 99%, and the light intensity distribution is relatively uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com