A kind of magnesium alloy material for oil and gas development and its preparation method and application

A technology of oil and gas exploitation and magnesium alloy, which is applied in the field of magnesium alloy materials and its preparation for oil and gas exploitation. It can solve the problems that the type and quantity of the second phase cannot be accurately predicted, prolong the supply cycle, and affect the progress of the project, so as to achieve uniform and accurate degradation. Controllable, improve efficiency and safety, ensure safety and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

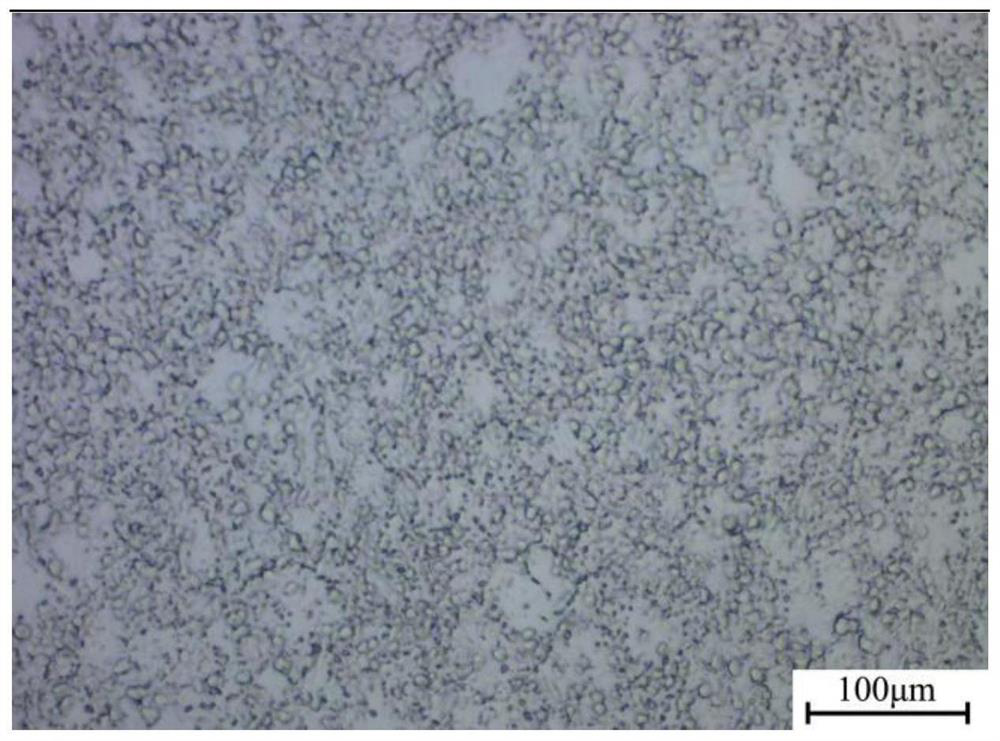

Embodiment 1

[0047] A variety of as-cast Mg-MM-1%Sn alloys were prepared, and the prepared components are shown in Table 1. The preparation method is: using pure magnesium ingot, cerium-rich mixed rare earth, pure Sn powder, pure Ti powder, pure Cu powder, pure Ni powder, pure Fe powder as raw materials, pure Sn powder, pure Ti powder, pure Cu powder, pure Ni powder , pure Fe powder purity is greater than 99.99%, particle size is less than 10um, carries out material preparation respectively by the weight percent of the composition of the magnesium alloy of Table 1;

[0048] The magnesium ingot is completely melted under the protection of protective gas, and the temperature is controlled at 760°C; the cerium-rich mixed rare earth, cerium-rich mixed rare earth, pure Sn powder, pure Ti powder, pure Cu powder, pure Ni powder, pure Fe powder are mixed at 200 After 2 hours of heat preservation in the preheating furnace at ℃, the cerium-rich mixed rare earth is first added to the magnesium melt f...

Embodiment 2

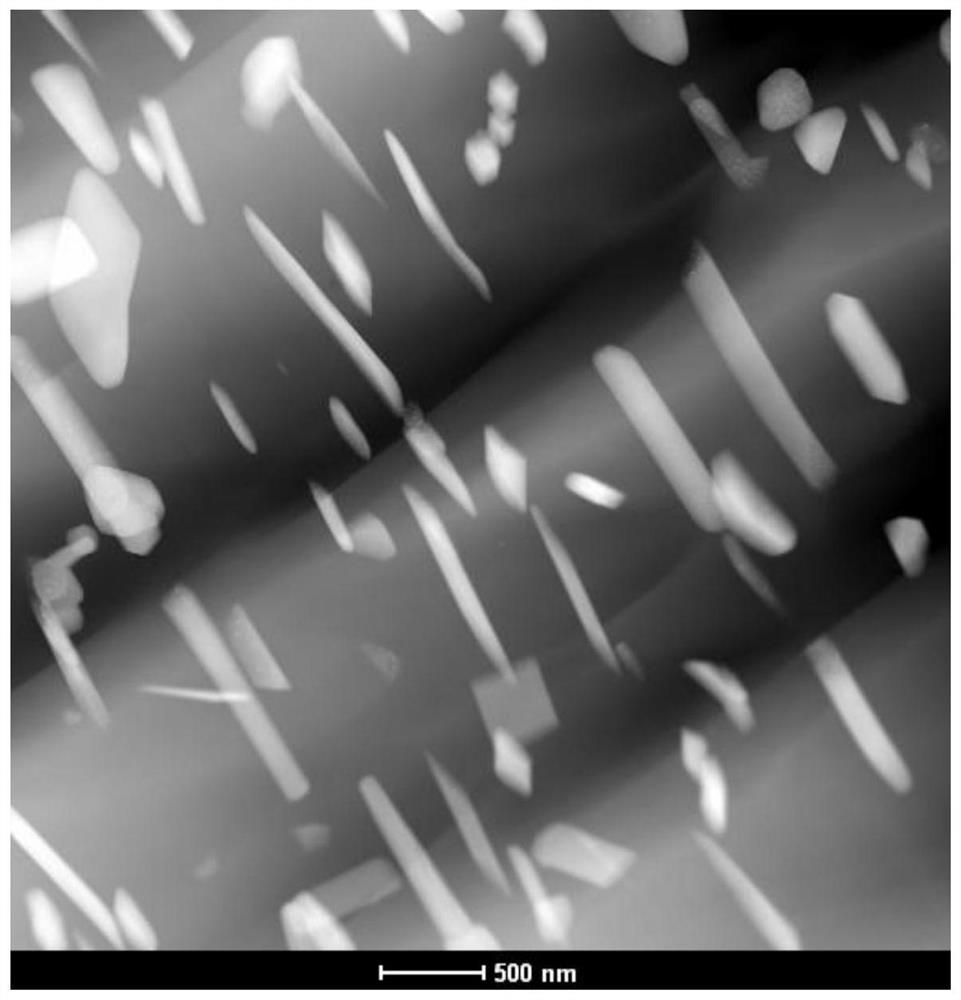

[0059] According to the composition and method of the present invention, three kinds of ingots have been prepared, which are respectively: cerium-rich mixed rare earth (Ce: 45wt.%; La: 35wt.%; Nd: 10wt.%; Pr: 10wt.%): 5wt .%, Sn: 2wt.%, 0.5wt.% Ti, the balance Mg; cerium-rich mixed rare earth (Ce: 45wt.%; La: 35wt.%; Nd: 10wt.%; Pr: 10wt.%): 5wt .%, Sn: 1wt.%, 0.5wt.% Ti, the balance Mg; cerium-rich mixed rare earth (Ce: 45wt.%; La: 35wt.%; Nd: 10wt.%; Pr: 10wt.%): 5wt .%, 0.5wt.% Ti, balance Mg;

[0060] Pure magnesium ingot, cerium-rich mixed rare earth, pure Sn powder, pure Ti powder, pure Cu powder, pure Ni powder, pure Fe powder as raw materials, pure Sn powder, pure Ti powder, pure Cu powder, pure Ni powder, pure Fe powder The purity is greater than 99.99%, and the particle size is less than 10um, and the materials are prepared according to the weight percentage of the above-mentioned magnesium alloy composition;

[0061] The magnesium ingot is completely melted under ...

Embodiment 3

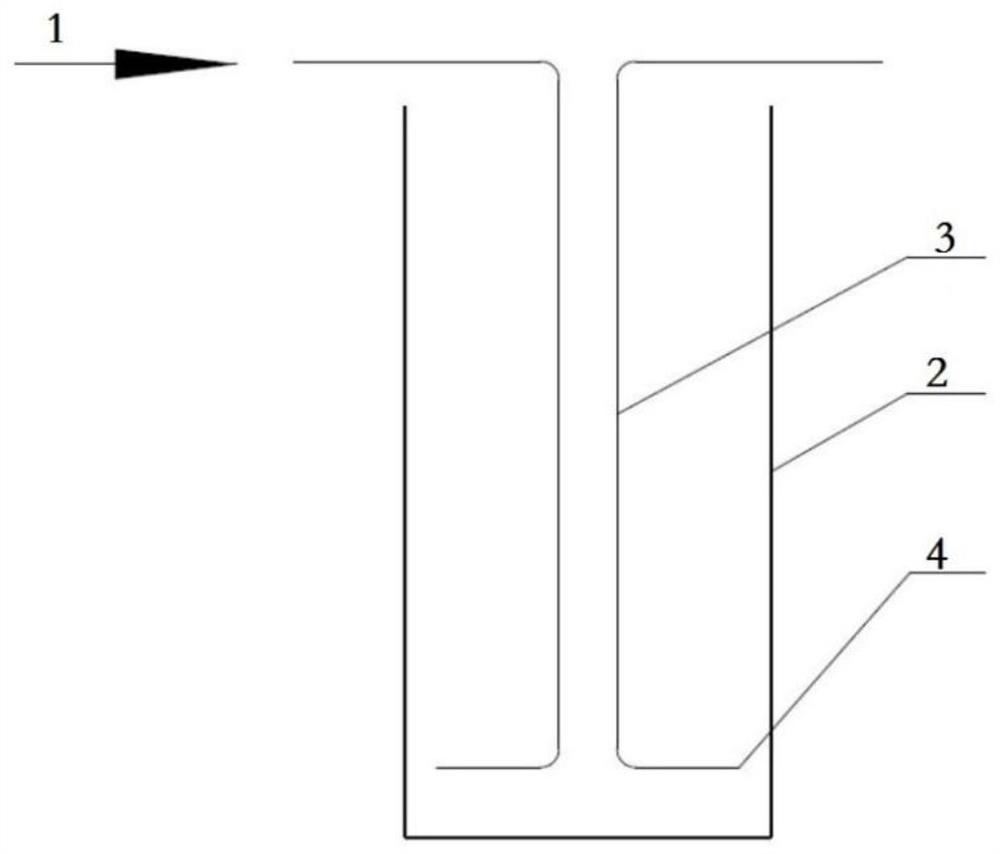

[0067] An oil field needs soluble bridge plugs, and the oil and gas well environment is: temperature 120°C, pressure 70Mpa, Cl - The ion content is 3%, the oil-water ratio is 80%, and the time difference between before and after the bridge plug is put into the well is about 36h. The strength of the bridge plug is required to be greater than 250MPa. Under this environment, the bridge plugs that are run first and then run into the well will degrade synchronously 12 hours after the last bridge plug is put into the well.

[0068] According to the oil field conditions and actual application requirements, ingots with alloy components of three components were prepared, respectively:

[0069] 1) Proportional Ce: 50wt.%; La: 30wt.%; Nd: 15wt.%; Pr: 5wt.%; mix the metal powder evenly to obtain cerium-rich mixed rare earth;

[0070] Using pure magnesium ingot, cerium-rich mixed rare earth, pure Sn powder, and pure Ni powder as raw materials, cerium-rich mixed rare earth: 4.5wt.%, Sn: 0.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com