A kind of efficient 5g ceramic dielectric filter conductive silver paste and preparation method thereof

A technology of ceramic medium and conductive silver paste, which is used in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc. It can solve the problems of unsatisfactory dispersion of conductive silver paste and improve metallization efficiency , Improve the effect of dispersion and rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also discloses a method for preparing the above-mentioned high-efficiency 5G ceramic dielectric filter conductive silver paste. The solvent and the dispersant are divided into parts for standby use, and the specific number of parts is distributed according to needs, which specifically includes the following steps:

[0050]1) According to the preset mass percentage, mix the organic binder into the solvent I, and stir the rotor at 20-40 rpm at 30-60°C for 5-15 minutes, and form glue after stirring evenly. The glue is divided into spare parts; preferably, the rotor can be rotated at 25-35 rpm at 40-50°C and stirred for 10 minutes;

[0051] 2) Put the solvent II, glue I, silver powder, and dispersant I into the power mixing mixer according to the preset mass percentage, and stir while feeding, and the stirring bar rotates at 20-50 rpm. Speed 25-35 rpm;

[0052] 3) Continue to stir the mixture obtained in step 2) for 15-30 minutes, the speed of the s...

Embodiment 1

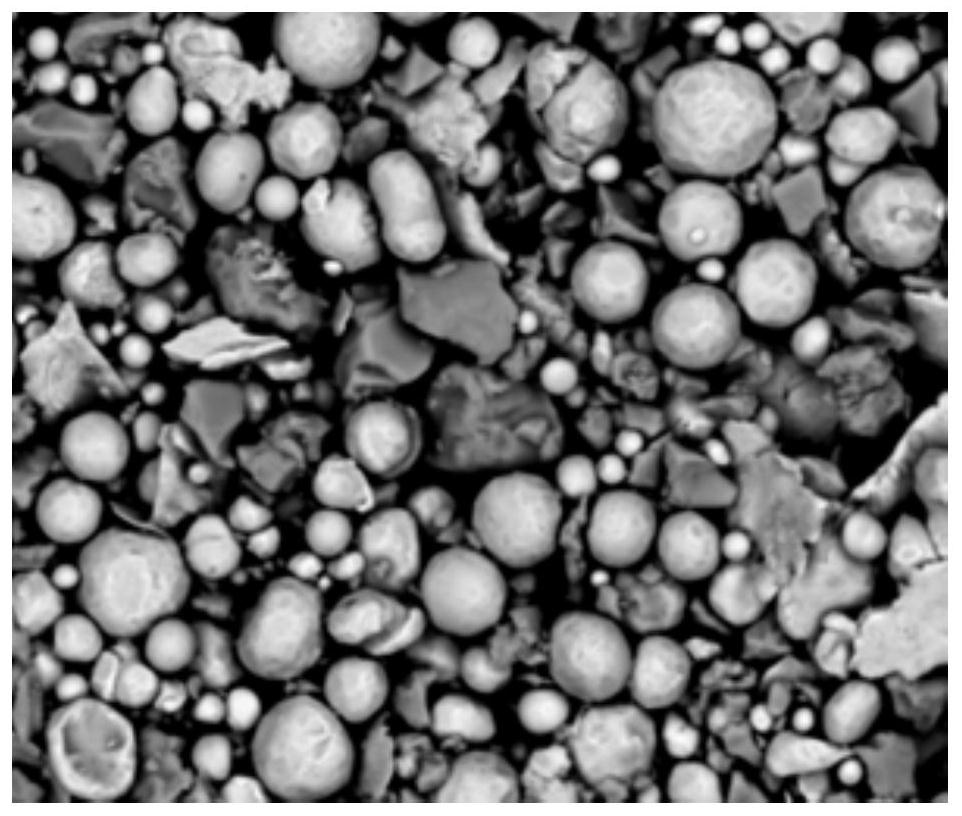

[0061] A high-efficiency 5G ceramic dielectric filter conductive silver paste, including the following components by mass percentage: 89% spherical silver powder, 1.5% glass powder, 1.5% ethyl cellulose, 0.1% magnesium oxide additive and 7.5% benzyl alcohol, Polymethacrylamide 0.30%, hydrogenated castor oil 0.1%. Among them, the particle size of the spherical silver powder is 0.3 μm, and the glass powder is Bi 2 o 3 -BO-SiO 2- Ag 2 O system glass powder, glass powder particle size 0.2μm, magnesium oxide particle size 0.1μm.

[0062] Prepared as follows:

[0063] Divide the benzyl alcohol solvent into 5 parts, and the polymethacrylic amine dispersant into 3 parts for later use. The specific parts are distributed according to the needs, and the corresponding fractions are marked with Roman numerals. The specific steps are as follows:

[0064] 1) According to the preset mass percentage, mix ethyl cellulose with benzyl alcohol solvent Ⅰ, and stir the rotor at 30 rpm at 50°C f...

Embodiment 2

[0075] The difference from Example 1 is that the high-efficiency 5G ceramic dielectric filter conductive silver paste includes the following components by mass percentage: spherical silver powder 90%, glass powder 1.8%, ethyl cellulose 1.0%, magnesium oxide Additive 0.1% and benzyl alcohol 6.7%, polymethacrylic acid amine 0.30%, hydrogenated castor oil 0.1%. Among them, the particle size of the spherical silver powder is 0.3 μm, and the glass powder is Bi 2 o 3 -BO-SiO 2- Ag 2 O system glass powder, glass powder particle size 0.2μm, magnesium oxide particle size 0.1μm. The fineness of the conductive silver paste for the filter is 2 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com