Continuous rectification device of isocyanate and rectification process thereof

An isocyanate and rectification technology, which is applied in the purification/separation, fractionation, and distillation separation of isocyanate derivatives, can solve the problems of easy polymerization of isocyanates at high temperature, difficult separation of impurities, and high energy consumption. Distillation efficiency, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

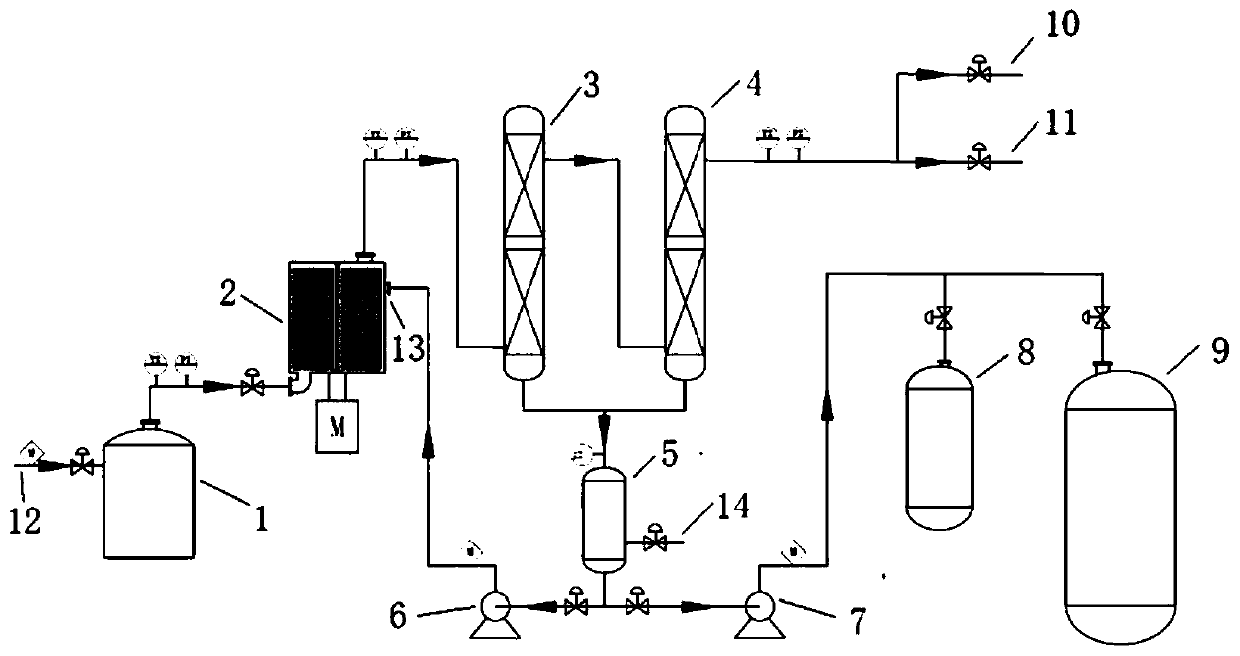

[0042] The crude product of 1,5-pentane diisocyanate containing 10% of solvent, 1% of impurity and 89% of 1,5-pentane diisocyanate was rectified.

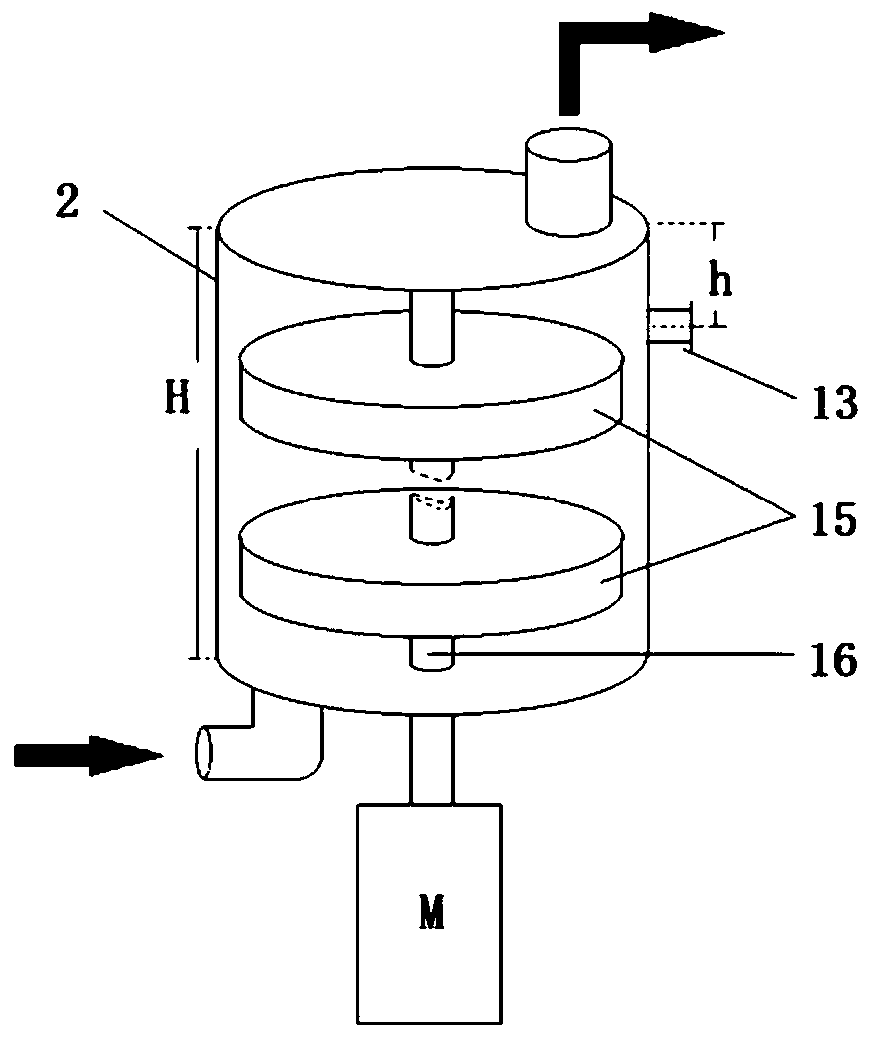

[0043] The total number n of packing layers in the supergravity separator is 3; the vertical gap h3 between adjacent packing layers is 20mm; the ratio of the outer diameter d1 of the packing layer to the inner diameter D of the separator is 0.96; the height of the packing layer h2 is related to the packing layer The ratio of the outer diameter d1 is 0.35:1; the ratio of the diameter d2 of the central axis to the outer diameter d1 of the packing layer is 0.085:1; the total height of the three packing layers htotal=n×h2+2×h3, htotal and separation The ratio of the height H of the supergravity separator is 0.9:1; the ratio of the distance h1 from the center point of the return port of the supergravity separator to the top of the supergravity separator and the height H of the supergravity separator is 0.1:1.

[0044] Pump the above-men...

Embodiment 2

[0046] Using the same rectification device as in Example 1, the crude 1,5-pentane diisocyanate containing 2% solvent, 0.8% impurities and 97.2% 1,5-pentane diisocyanate was rectified.

[0047] Pump the above-mentioned crude 1,5-pentanediisocyanate into reboiler 1, close the inlet valve of reboiler 1, open all other valves, connect the outlet of the upper end of the second condenser 4 to the vacuum system, and reduce the system pressure to - Below 0.098MPa, close the reflux pump 6 inlet valve, the discharge pump 7 inlet valve, and the product receiving tank 9 inlet valve; then turn on the supergravity separator 2 motor and adjust the speed to 1000r / min; set the reboiler 1 temperature to 115 ℃, the supergravity outlet gas phase temperature is 100 ℃; after the distillate enters the buffer tank, open the inlet valve of the reflux pump 6, turn on the reflux pump 6 and adjust the reflux ratio to 3:1; open the inlet valve of the discharge pump 7, and turn on the discharge pump 7 and ...

Embodiment 3

[0049] Rectify the crude m-xylylene diisocyanate containing 5% solvent, 1% impurity and 94% m-xylylene diisocyanate.

[0050] The total number n of packing layers in the supergravity separator is 4; the vertical gap h3 between adjacent packing layers is 15mm; the ratio of the outer diameter d1 of the packing layer to the inner diameter D of the separator is 0.97; the height of the packing layer h2 is related to the packing layer The ratio of the outer diameter d1 is 0.38:1; the ratio of the diameter d2 of the central axis to the outer diameter d1 of the packing layer is 0.09:1; the total height h total of the four packing layers = n×h2+3×h3, h total and separation The ratio of the height H of the supergravity separator to the height H of the supergravity separator is 0.15:1.

[0051] The above-mentioned m-xylylene diisocyanate crude product is pumped into the reboiler 1, the valve of the feed port of the reboiler 1 is closed, all the other valves are opened, the outlet at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| turbidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com