A manufacturing process for target crystal grain miniaturization

A target and grain technology, applied in metal material coating process, manufacturing tools, metal rolling, etc., can solve the problems of insufficient concentration of size distribution, large target grain size, high production cost, etc., and achieve the concentration of size distribution , Small target grain size, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

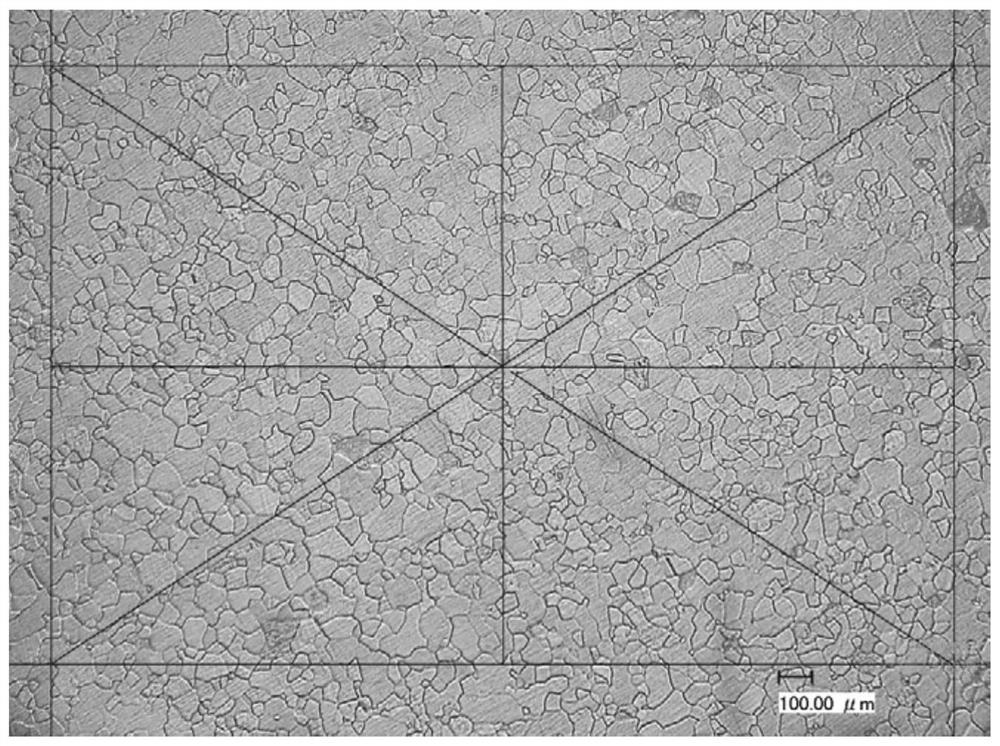

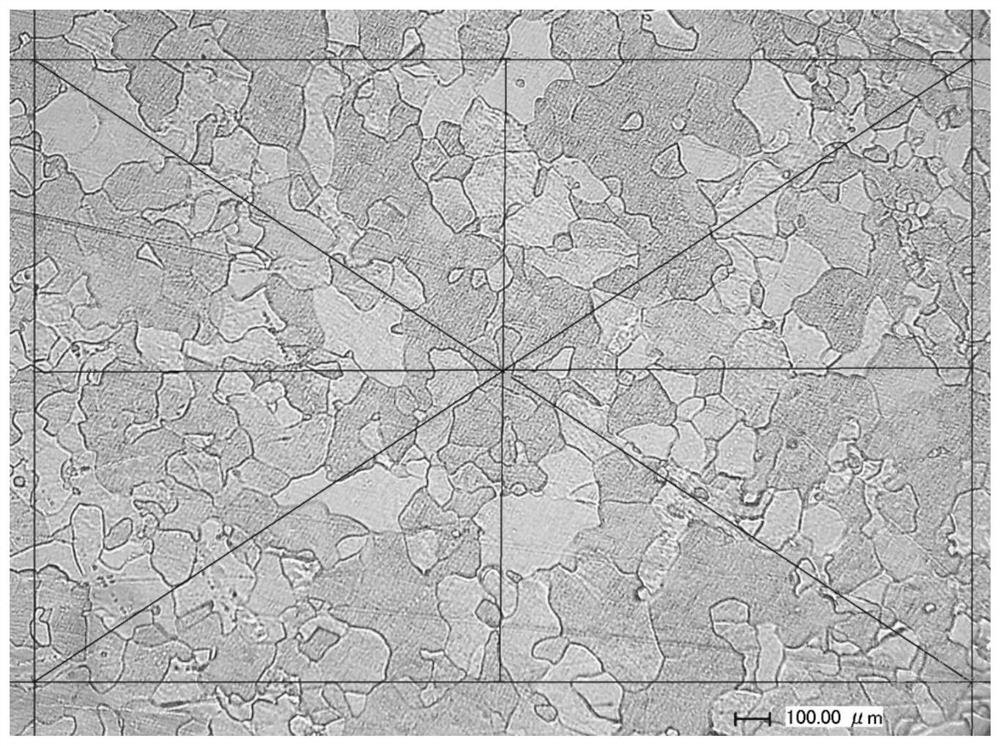

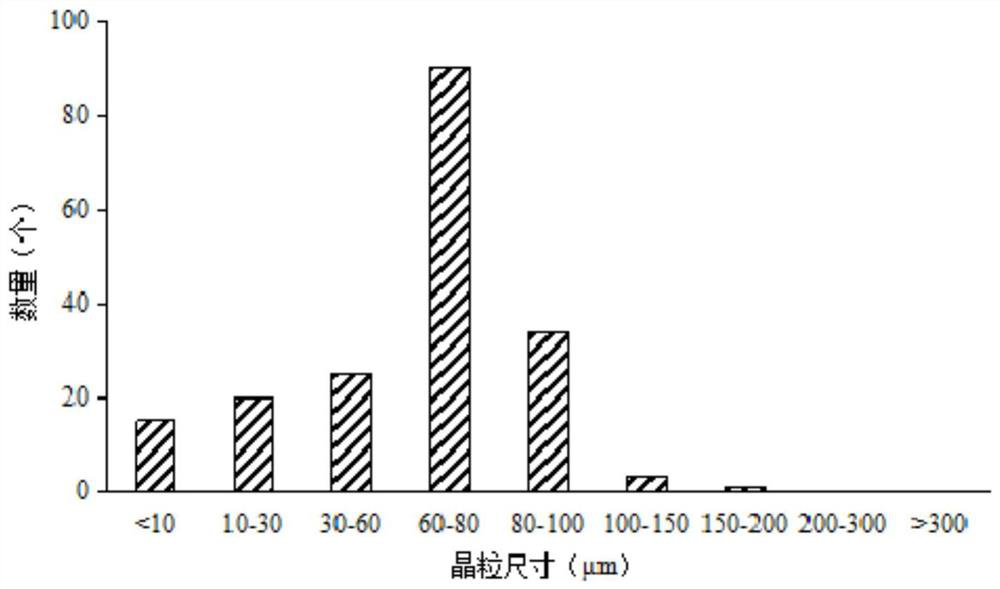

Image

Examples

Embodiment 1

[0036] A manufacturing process for target crystal grain miniaturization, comprising the following steps:

[0037] (1) One-time rolling: Put the aluminum ingot into the heating furnace, set the maximum temperature of the furnace body to 250°C, use the temperature detection head in the heating furnace to observe the temperature of the aluminum ingot in real time, when the actual temperature of the aluminum ingot is 170°C, Rolling the aluminum ingot once;

[0038] Among them, in one calendering, it is divided into 13 passes, and the reduction amount of each pass is 20mm. After the calendering is completed, cut off the irregular parts of the head and tail of the calendered plate to obtain a semi-finished target material; the thickness of the semi-finished target material It is 118mm.

[0039] (2) Secondary calendering: Put the semi-finished target material into the heating furnace, set the maximum heating temperature of the furnace body to 380°C, use the temperature detection hea...

Embodiment 2

[0043] A manufacturing process similar to that of Example 1 was adopted, except that in the first rolling step of step (1), when the actual temperature of the aluminum ingot was 220° C., the aluminum ingot was rolled once. The finished target material is denoted as S2.

[0044] Calculate the step retention rate during the target material manufacturing process, and the final step retention rate = 93-95%.

Embodiment 3

[0046] A manufacturing process similar to that of Example 1 was adopted, except that in the second calendering step of step (2), when the actual temperature of the semi-finished target was 350° C., the semi-finished target was subjected to secondary calendering. The finished target material is denoted as S3.

[0047] Calculate the step retention rate during the target material manufacturing process, and the final step retention rate = 93-95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com