Carburetant for steelmaking and preparation method thereof

The technology of recarburizer and adhesive is applied in the field of recarburizer for steelmaking and its preparation, which can solve the problems of poor compatibility of recarburizer, burning loss, and poor carburization effect, and achieves improved stability of recarburization. performance, reduce production costs, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

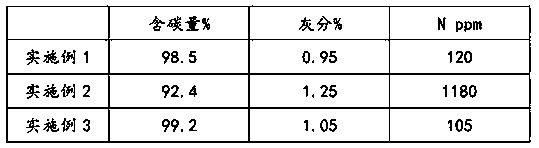

Examples

Embodiment 1

[0019] A recarburizer for steelmaking, comprising the following components in parts by weight: 300 parts of a carbon-containing mixture, 5 parts of silicon nitride, 3 parts of a dispersant, and 2 parts of a binder; the carbon-containing mixture is made of petroleum Coke powder, waste straw powder, and nano-carbon are mixed according to the molar ratio of 50:23:5. Under nitrogen environment, the temperature is raised to 1500°C at a rate of 3°C / min. Ball mill to 200 mesh sieve to obtain carbon-containing mixture.

[0020] The adhesive is formed by mixing an organic adhesive and an inorganic adhesive, and the mass ratio of the organic adhesive to the inorganic adhesive is 2:1. When the organic binder is modified starch, the modified starch is formed by mixing starch, chitosan and iron powder according to a molar ratio of 5:1:3, and the preparation method of the modified starch is as follows: After dissolving in water, add chitosan and stir evenly, then add iron powder, continue ...

Embodiment 2

[0024] A recarburizer for steelmaking, comprising the following components in parts by weight: 4500 parts of carbon-containing mixture, 10 parts of silicon nitride, 6 parts of dispersant, and 6 parts of binder; the carbon-containing mixture is made of petroleum Coke powder, waste straw powder, and nano-carbon are mixed according to the molar ratio of 75:30:8. Under nitrogen environment, the temperature is raised to 1685°C at a rate of 8°C / min. , ball milled to a 260 mesh sieve to obtain a carbon-containing mixture.

[0025] In the above raw materials, the adhesive is mixed with an organic adhesive and an inorganic adhesive, and the mass ratio of the organic adhesive to the inorganic adhesive is 2:1; the organic adhesive is modified Mix one or more of starch, nitrile rubber or sodium hydroxymethyl cellulose.

[0026] It is further improved that the modified starch is formed by mixing starch, chitosan and iron powder according to a molar ratio of 5:1:3, and the preparation meth...

Embodiment 3

[0029] A recarburizer for steelmaking, comprising the following components in parts by weight: 500 parts of a carbon-containing mixture, 12 parts of silicon nitride, 10 parts of a dispersant, and 8 parts of a binder; the carbon-containing mixture is made of petroleum Coke powder, waste straw powder, and nano-carbon were mixed according to the molar ratio of 80:32:10. Under nitrogen environment, the temperature was raised to 1785°C at 7°C / min, kept for 1h, and then refrigerated at 4°C for 2h. Mesh sieve to obtain carbon-containing mixture.

[0030] The adhesive is formed by mixing an organic adhesive and an inorganic adhesive, and the mass ratio of the organic adhesive to the inorganic adhesive is 2:1. The modified starch is formed by mixing starch, chitosan and iron powder according to the molar ratio of 5-6:1:3. The preparation method of the modified starch is: after dissolving the starch in water, add chitosan and stir Evenly, add iron powder, continue to stir, and heat unt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com