Real-time stress monitoring system and safety coefficient detection method for coupling bolt

A technology of stress monitoring and axial stress, which is applied in general control systems, control/regulation systems, force/torque/power measuring instruments, etc., can solve problems such as abnormal vibration of units, reduction of equipment life, fatigue damage of fasteners, etc. Achieve the effect of low environmental requirements, improve work efficiency and reduce workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

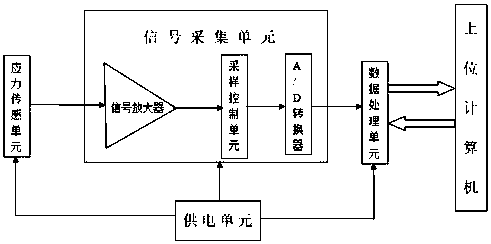

[0075] The invention discloses a real-time stress monitoring system for shaft coupling bolts. As a basic embodiment of the invention, it includes a hydroelectric generator set, a power supply unit, a stress sensing unit, a signal sampling unit, a data processing unit and a host computer; The hydroelectric generating set includes the coupling bolt body and the turbine cover; the power supply unit is arranged inside or outside the turbine cover, and is respectively connected to the stress sensing unit, signal sampling unit and data processing unit through wires; the stress sensing unit includes Several stress sensors, the stress sensor is set on the coupling bolt body, connected to the signal sampling unit through wires; the signal sampling unit is set on the inside or outside of the turbine cover, including signal amplifier, sampling control unit and A / D converter ; The signal input end of the sampling control unit is connected with the stress sensing unit through the signal amp...

Embodiment 2

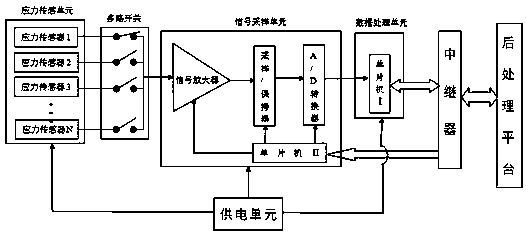

[0078]The invention discloses a real-time stress monitoring system for shaft coupling bolts. As a preferred embodiment of the invention, that is, in Example 1, a wireless data connection is adopted between the data processing unit and the upper computer; the data processing unit and the upper computer A repeater is arranged between them; the sampling control unit includes a single-chip microcomputer II and a sample / hold device; a multi-way switch is arranged between the stress sensing unit and the signal amplifier.

[0079] The performance of the signal sampling unit depends on the sampling accuracy and sampling speed. Under the condition of ensuring that the signal sampling unit has sampling accuracy, there is as high a sampling speed as possible to meet the requirements of real-time processing and control. Therefore, this technical solution adopts a program-controlled data sampling system, that is, a single-chip microcomputer is added to the data sampling control unit Ⅱ. Rea...

Embodiment 3

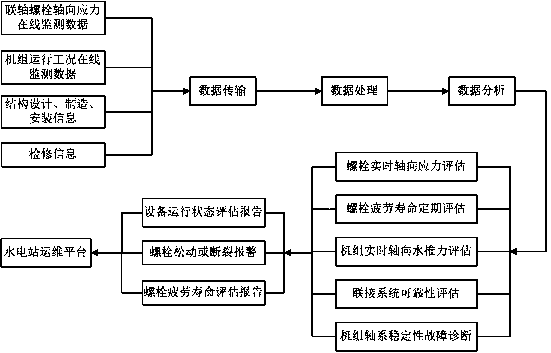

[0081] The invention discloses a method for detecting the safety factor of coupling bolts, as a basic embodiment of the invention, including preliminary preparation, data collection, data processing, data call and display;

[0082] Preliminary preparation refers to the logic control program written into the data processing unit through the upper computer, including the real-time axial stress evaluation program of bolts, the fatigue life evaluation program of coupling bolts, the real-time axial water thrust evaluation program of the unit, and the reliability evaluation program of the connection system , Shafting stability fault diagnosis program, and set the bolt real-time axial stress amplitude alarm threshold and bolt fatigue damage alarm threshold;

[0083] Real-time axial stress evaluation of bolts: When the bolts are well pre-tightened, based on the online monitoring stress of the bolts and the real-time working condition data of the unit, the real-time stress state of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com