Method for preparing attapulgite-based pH value response antibacterial material

An antibacterial material, the technology of attapulgite, which is applied in the field of preparation of attapulgite-based pH-responsive antibacterial materials, can solve the problems of strong volatility, pungent odor, and easy oxidation of aldehyde natural antibacterial agents, so as to improve utilization efficiency, Improving palatability, overcoming volatile and pungent strong-odor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

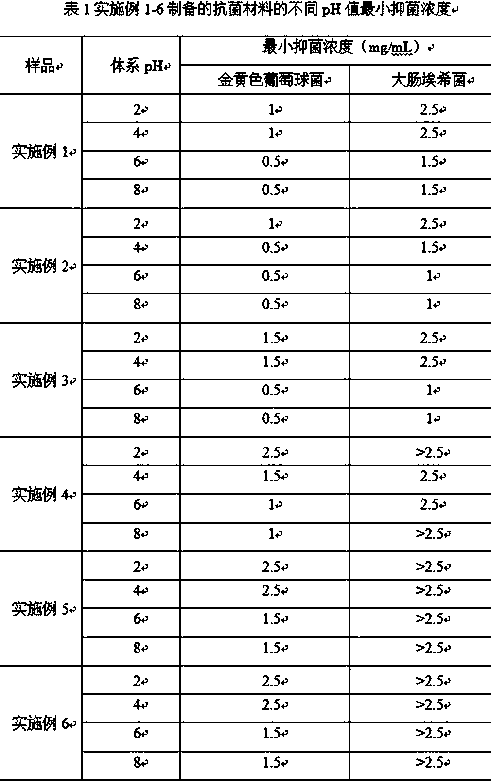

[0026] Spray 30% citral relative to the mass fraction of attapulgite on the surface of attapulgite under stirring, keep stirring for 30 minutes, then place it in a ball mill for 30 minutes (ball-to-material ratio 1:10); then place it in a stirring tank, Spray chitosan-citric acid aqueous solution (the concentration of chitosan in the system is 5%, and the concentration of citric acid is 2.5%) relative to the mass of attapulgite with 7.5% chitosan. After spraying, keep stirring for 30 minutes, and finally dry the material Dry, sieve, and pack to obtain the antibacterial material. The antibacterial properties of antibacterial materials are shown in Table 1.

Embodiment 2

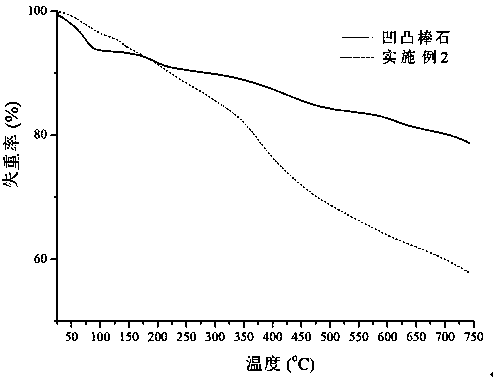

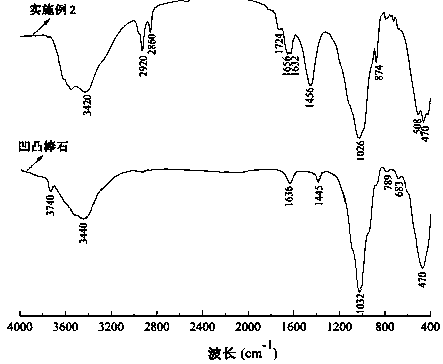

[0028] Under stirring, spray cinnamaldehyde 25% relative to the mass fraction of attapulgite on the surface of attapulgite, keep stirring for 30 minutes, put it in a ball mill for 40 minutes (ball-to-material ratio 1:10), and then put it in a stirring tank. Spray chitosan-citric acid aqueous solution with 10% chitosan relative to attapulgite mass fraction (chitosan concentration in the system is 7.5%, citric acid concentration is 1%), keep stirring for 45min after spraying, and finally dry the material , sieving, and packaging to obtain the antibacterial material. The antibacterial properties of antibacterial materials are shown in Table 1.

Embodiment 3

[0030] Spray 40% lauryl aldehyde relative to the mass fraction of attapulgite on the surface of attapulgite under stirring, keep stirring for 30 minutes, then put it in a ball mill and grind it for 50 minutes (ball-to-material ratio 1:10), and then put the material in a mixing tank , spray chitosan-citric acid aqueous solution (chitosan concentration 10% and citric acid concentration 2.5% in the system) relative to attapulgite mass of 15% chitosan, keep stirring for 60min after spraying, and finally dry the material , sieving, and packaging to obtain the antibacterial material. The antibacterial properties of antibacterial materials are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com