Method for preparing fish oil and resveratrol co-embedded microcapsule powder

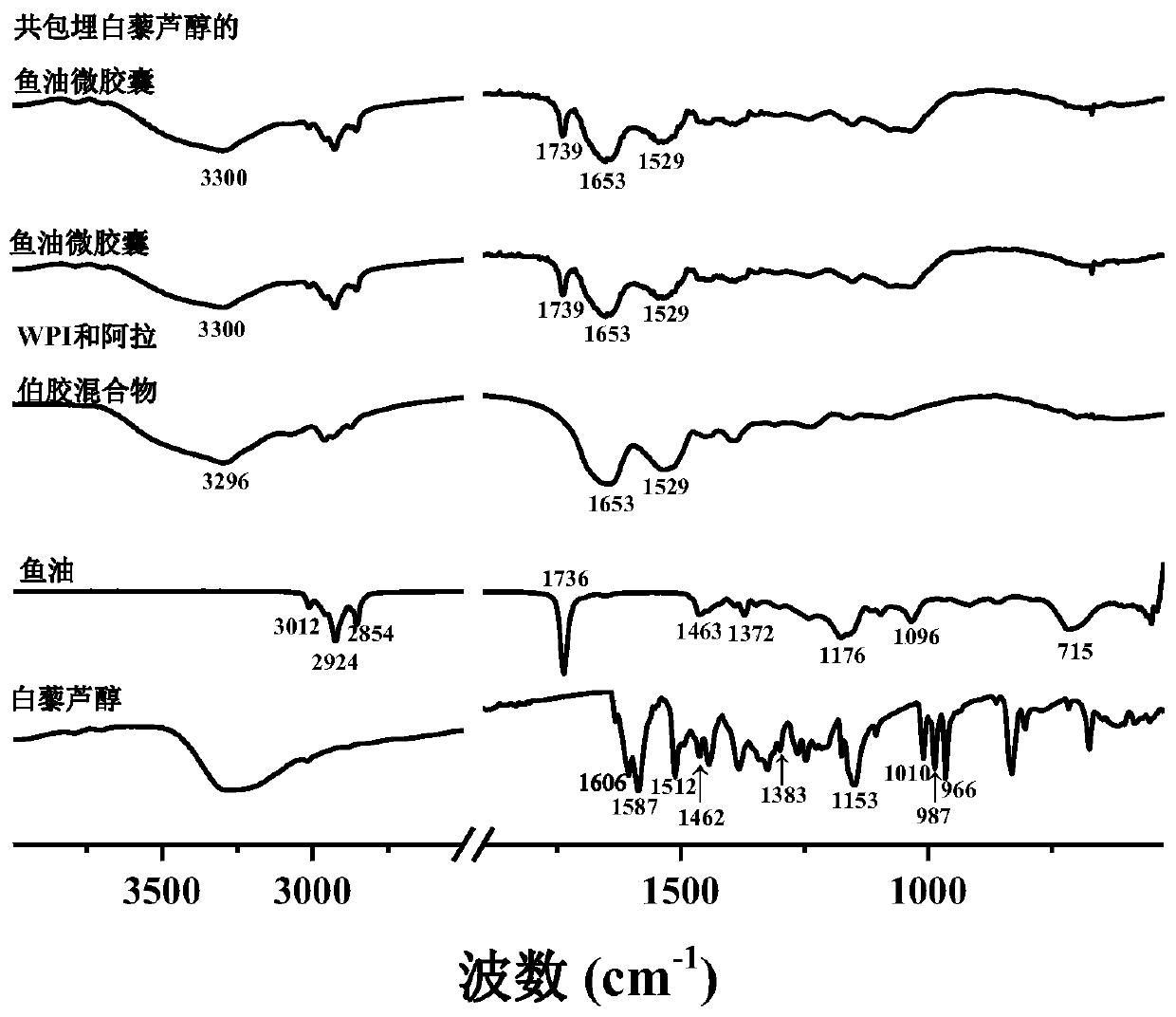

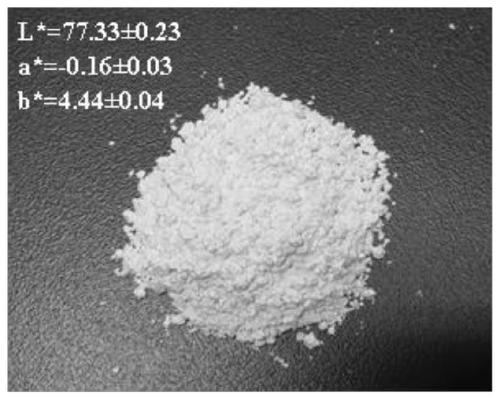

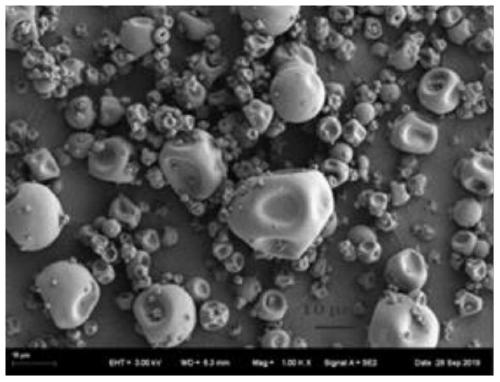

A technology of resveratrol and microcapsules, which is applied in the field of food processing to achieve the effect of complete particles, low water activity and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Example 1: Preparation of fish oil and resveratrol co-embedded microcapsules

[0050] (1) Enzyme cross-linking of whey protein isolate: 1.67 g of transglutaminase was added to 56 mL of 25% whey protein isolate solution at pH 7 for cross-linking; wherein, the enzyme activity was 8 U / g protein, and the cross-linking temperature was 50°C, and the crosslinking time was 90 minutes.

[0051] (2) Preparation of emulsion: Add 3.52 mL of 0.0505 g / mL resveratrol ethanol solution to the cross-linked whey protein isolate aqueous solution, stir for 30 minutes, and prepare whey protein isolate-resveratrol nanoparticles ; Then, add 9.34g of fish oil, high-speed shearing at 16000rpm for 2 minutes, and homogenize 3 times at 10°C and 50MPa; finally, add a pH7 aqueous solution of gum arabic. The composition of the final emulsion is: by mass percentage, 15% whey protein isolate, 5% gum arabic, 10% fish oil, 0.19% resveratrol.

[0052] (3) Prepare whey protein isolate-resveratrol-gum arab...

Embodiment 2

[0062] Embodiment 2: the selection of wall material consumption

[0063] 1. Prepare WPI-stabilized fish oil and resveratrol emulsion with reference to step (2) of Example 1. The difference is that WPI is not enzymatically cross-linked and has different concentrations, such as 0.5%, 1%, 2%, 5%, 6% %, 10%, 12% and 15%, the specific methods are as follows:

[0064] Add 3.52mL 0.0505g / mL resveratrol ethanol solution to whey protein isolate aqueous solution, stir for 30 minutes, prepare whey protein isolate-resveratrol nanoparticles; then, add 9.34g fish oil, under 16000rpm condition Shear at high speed for 2 minutes, and homogenize 3 times under the conditions of 10°C and 50MPa. The composition of the final emulsion is: by mass percentage, 0.5%, 1%, 2%, 5%, 6%, 10%, 12% or 15% whey protein isolate and 10% fish oil.

[0065] Table 2 shows the content of resveratrol at the interface of fish oil emulsions stabilized with different concentrations of WPI. It can be seen from Table 2 ...

Embodiment 3

[0075] Embodiment 3: the selection of enzyme dosage

[0076] 1. Prepare co-embedded microcapsule powder with reference to the preparation method of Example 1. The difference is that the enzyme activity of transglutaminase is different, and no resveratrol is added. The specific method is as follows:

[0077] (1) Enzyme cross-linking of whey protein isolate: Add 1.04, 1.25, 1.67 g of transglutaminase to 56 mL of 25% whey protein isolate solution at pH 7 for cross-linking, and the corresponding enzyme activity is 5, 6, 8 U / g protein, the crosslinking temperature was 50°C, and the crosslinking time was 90 minutes.

[0078] (2) Preparation of emulsion: add 9.34g fish oil to the cross-linked whey protein isolate aqueous solution, shear at high speed for 2 minutes at 16000rpm, homogenize 3 times at 10°C and 50MPa; finally, add Gum Arabic pH 7 aqueous solution. The composition of the final emulsion is: by mass percentage, 15% whey protein isolate, 5% gum arabic, and 10% fish oil. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com