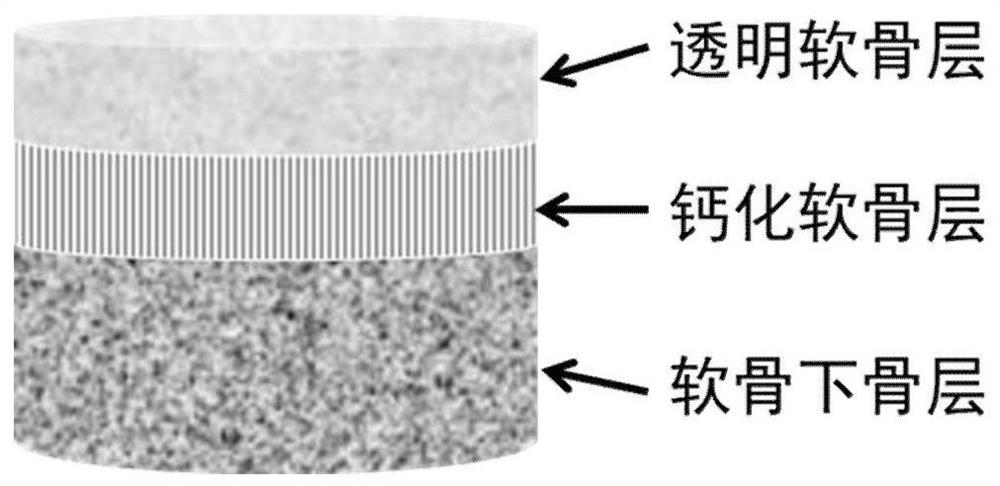

A biomimetic heterogeneous integrated bone-cartilage repair scaffold and preparation method thereof

A cartilage repair and calcified cartilage technology, applied in the direction of prosthesis, tissue regeneration, medical science, etc., can solve the problems of lack of multi-level structure and weak interface bonding force, and achieve the effect of promoting stability and enhancing the mechanical properties of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. Preparation of Subchondral Bone Layer Precursors

[0054] (1) Dissolve 1.00 g of chitosan in an acetic acid solution with a volume fraction of 2%, and stir magnetically for 30 min under a water bath at 37°C to obtain a chitosan acid solution;

[0055] (2) 8 mL each of 2 mol / L calcium nitrate solution and 1.2 mol / L dipotassium hydrogen phosphate solution were added to the mixed solution obtained in step (1) in turn, and fully stirred to make them evenly mixed to obtain a subchondral bone layer complex Precursor solution; where the Ca / P molar ratio is n(Ca 2+ ):n(PO 4 3- ) = 1.67:1;

[0056] (3) injecting the homogeneous mixture of chitosan and inorganic ions prepared in (2) into a mold, and placing it in a refrigerator at -20°C to freeze to form solid A;

[0057] 2. Preparation of precursor complexes of calcified cartilage layer and subchondral bone layer

[0058] (4) Dissolving 0.75 g of chitosan in an acetic acid solution with a volume fraction of 2%, stirring ...

Embodiment 2

[0071] 1. Preparation of Subchondral Bone Layer Precursors

[0072] (1) Dissolve 1.00 g of chitosan in an acetic acid solution with a volume fraction of 2%, and stir magnetically for 30 min under a water bath at 37°C to obtain a chitosan acid solution;

[0073] (2) 8 mL each of 2 mol / L calcium nitrate solution and 1.2 mol / L dipotassium hydrogen phosphate solution were added to the mixed solution obtained in step (1) in turn, and fully stirred to make them evenly mixed to obtain a subchondral bone layer complex Precursor solution; where the Ca / P molar ratio is n(Ca 2+ ):n(PO 4 3- ) = 1.67:1;

[0074] (3) injecting the homogeneous mixture of chitosan and inorganic ions prepared in (2) into a mold, and placing it in a refrigerator at -20°C to freeze to form solid A;

[0075] 2. Preparation of precursor complexes of calcified cartilage layer and subchondral bone layer

[0076] (4) Dissolving 0.75 g of chitosan in an acetic acid solution with a volume fraction of 2%, stirring ...

Embodiment 3

[0089] 1. Preparation of Subchondral Bone Layer Precursors

[0090] (1) Dissolve 1.25 g of chitosan in an acetic acid solution with a volume fraction of 2%, and stir magnetically for 30 min under a water bath at 37°C to obtain a chitosan acid solution;

[0091] (2) 8 mL each of 2 mol / L calcium nitrate solution and 1.2 mol / L dipotassium hydrogen phosphate solution were added to the mixed solution obtained in step (1) in turn, and fully stirred to make them evenly mixed to obtain a subchondral bone layer complex Precursor solution; where the Ca / P molar ratio is n(Ca 2+ ):n(PO 4 3- ) = 1.67:1;

[0092] (3) injecting the homogeneous mixture of chitosan and inorganic ions prepared in (2) into a mold, and placing it in a refrigerator at -20°C to freeze to form solid A;

[0093] 2. Preparation of precursor complexes of calcified cartilage layer and subchondral bone layer

[0094] (4) Dissolve 1.00 g of chitosan in an acetic acid solution with a volume fraction of 2%, and stir ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com