A twin-shaft three-motor marine ammonia-electric hybrid power system

A technology of hybrid power system and three motors, which is applied in the field of ship power system, can solve the problems of endurance restriction, fuel waste, long charging time, etc., and achieve the effects of wide power coverage, poor dynamic response improvement and power generation efficiency optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

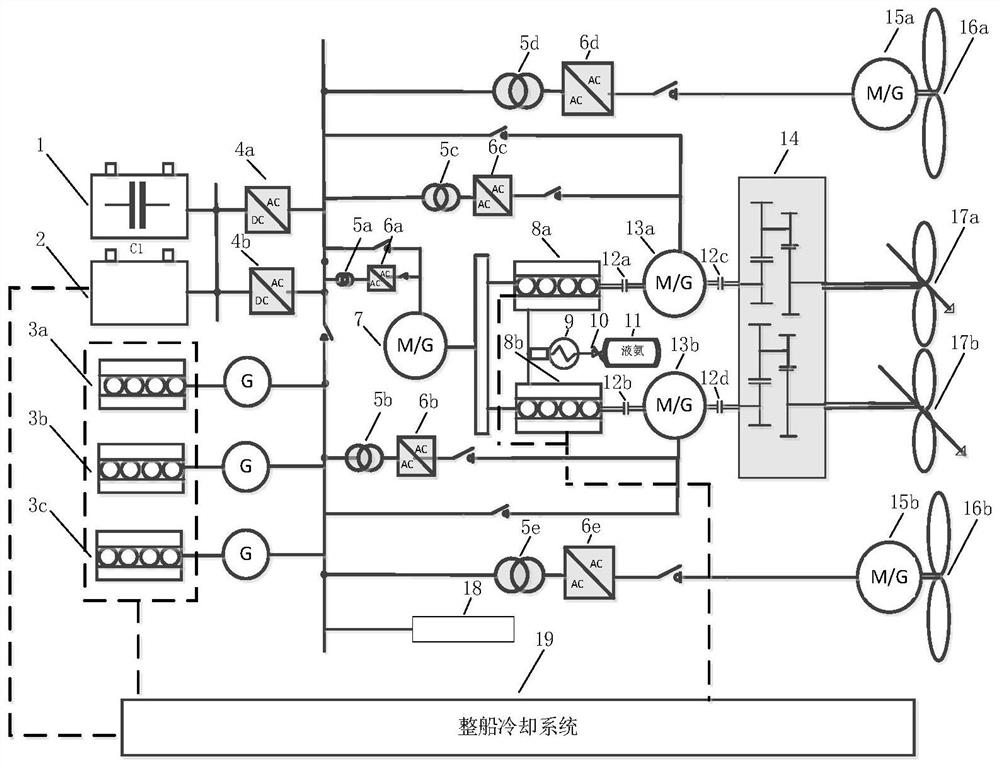

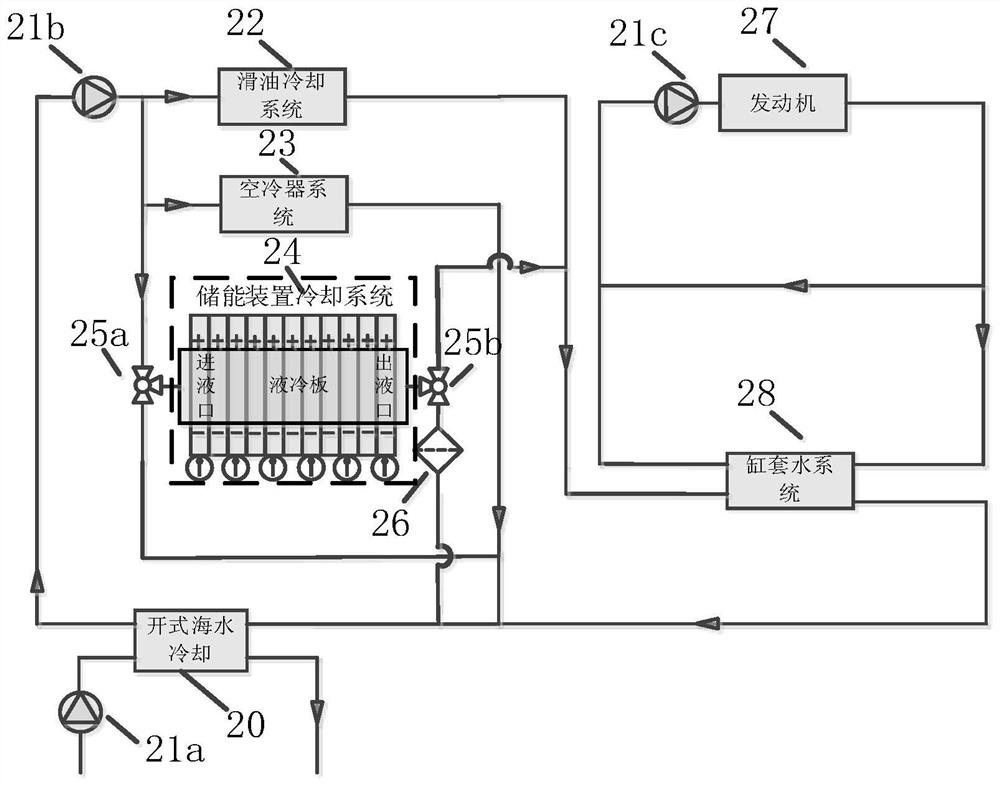

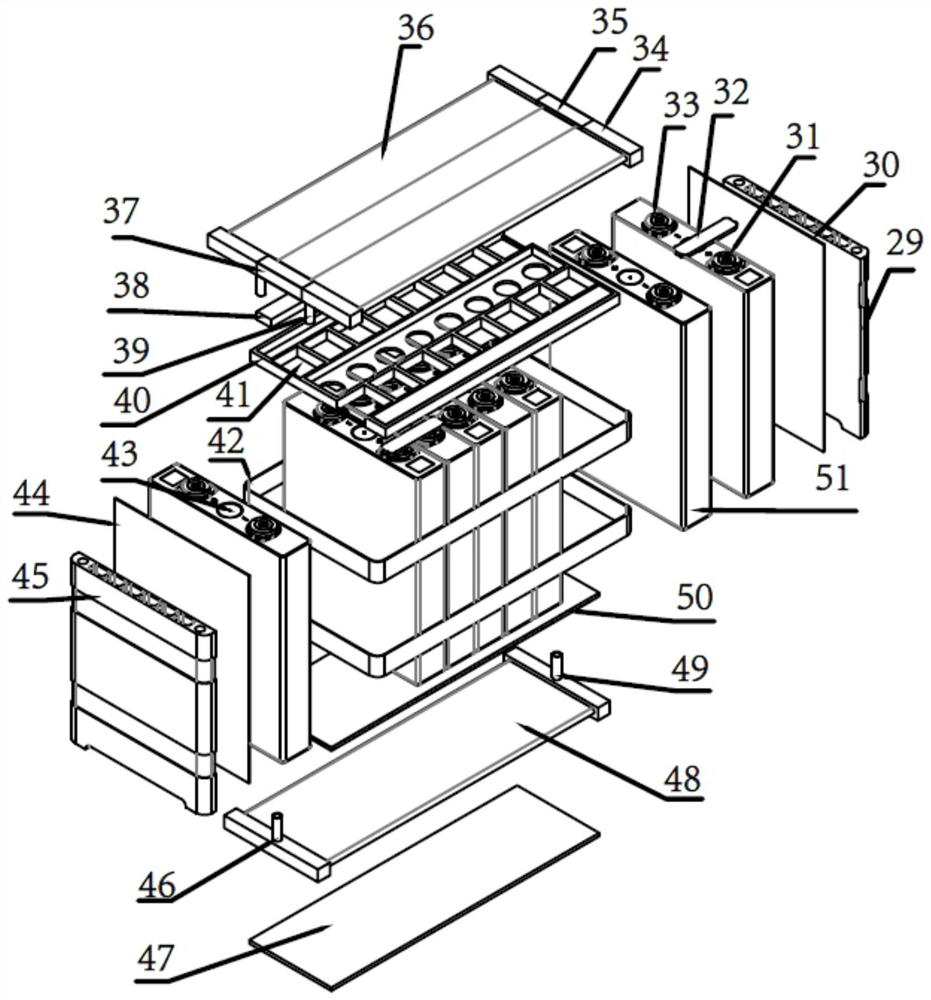

[0030] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0031] combine Figure 1-3 , see figure 1 , a dual-axis three-motor ship ammonia-electric hybrid power system of the present invention includes: supercapacitor 1, storage battery 2, diesel generator set 3a, 3b, 3c, power transformation device 4a, 4b, voltage transformation device 5a, 5b, 5c, 5d, 5e, frequency conversion device 6a, 6b, 6c, 6d, 6e, first reversible motor 7, ammonia fuel engine 8a, 8b, vaporization heat exchange device 9, stop valve 10, liquid ammonia tank 11, clutch 12a, 12b, 12c , 12d, the second reversible motor 13a, the third reversible motor 13b, gear box 14, the fourth reversible motor 15a, the fifth reversible motor 15b, fixed pitch propellers 16a, 16b, variable pitch propellers 17a, 17b, ship load 18 19. Cooling system for the whole ship.

[0032] The connection relationship is as follows: the first reversible motor 7 is connected to the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com