Recovery method of fiber reinforced composite material

A technology for reinforcing composite materials and composite materials, applied in the field of recycling fiber-reinforced composite materials, can solve the problems of harsh reaction conditions, low resin degradation rate, complex process, etc., and achieve the effects of simple operation, low reaction temperature and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

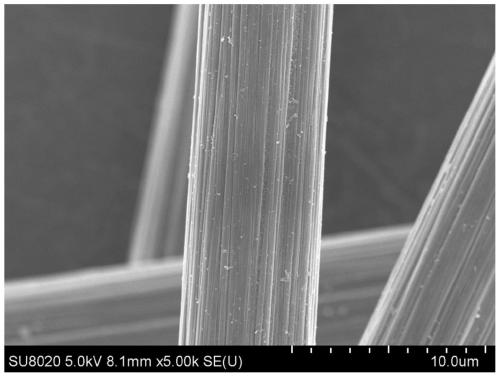

[0045] This embodiment provides a method for recycling fiber-reinforced composite materials, said method comprising the steps of:

[0046] (1) Mix and heat the fiber-reinforced composite material and acid, and then separate solid and liquid to obtain modified fibers and filtrate; wherein, the fiber-reinforced composite material includes carbon fiber-reinforced composite material; the acid is sulfuric acid; the acid The mass concentration is 98wt%; the mass ratio of the fiber reinforced composite material to the acid is 1:27.17; the heating method includes microwave heating; the power of the microwave heating is 20W; the heating time is 20min; The heating temperature is 100°C; the matrix resin of the fiber-reinforced composite material includes a thermosetting resin;

[0047] (2) Carbonize the filtrate obtained in step (1) to obtain a carbon material; wherein, the carbonization is to add biomass (rice husk) to the filtrate, and then perform the first temperature rise and the se...

Embodiment 2

[0050] This embodiment provides a method for recycling fiber-reinforced composite materials, said method comprising the steps of:

[0051] (1) Mix and heat the fiber-reinforced composite material and acid, and then separate solid and liquid to obtain modified fibers and filtrate; wherein, the fiber-reinforced composite material includes glass fiber-reinforced composite material; the acid is alkylated waste sulfuric acid The mass concentration of the acid is 88.2wt%; the mass ratio of the fiber reinforced composite material to the acid is 1:24.27; the heating method includes microwave heating; the power of the microwave heating is 100W; The time is 10 minutes; the heating temperature is 200°C; the matrix resin of the fiber-reinforced composite material includes a thermosetting resin;

[0052] (2) Carbonize the filtrate obtained in step (1) to obtain a carbon material; wherein, the carbonization is to add biomass (rice husk) to the filtrate, and then perform the first temperatur...

Embodiment 3

[0055] This embodiment provides a method for recycling fiber-reinforced composite materials, said method comprising the steps of:

[0056] (1) mixing and heating the fiber-reinforced composite material and acid, followed by solid-liquid separation to obtain modified fibers and filtrate; wherein, the fiber-reinforced composite material is included in the basalt fiber-reinforced composite material; the acid is sulfuric acid; the The mass concentration of the acid is 65wt%; the mass ratio of the fiber reinforced composite material to the acid is 1:14.39; the heating method includes microwave heating; the power of the microwave heating is 800W; the heating time is 300min; The heating temperature is 50°C; the matrix resin of the fiber-reinforced composite material includes a thermoplastic resin;

[0057] (2) Carry out carbonization treatment to the filtrate that step (1) obtains, obtain carbon material; Wherein, described carbonization treatment is to add catalyzer in filtrate, car...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com