A high-density nano-twinned high-performance nickel-aluminum-bronze alloy plate and its preparation method

A technology of alloy plate and nickel-aluminum-bronze, which is applied in the direction of metal rolling to achieve the effects of small grain size, rich application scenarios, and improved comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of as-cast nickel-aluminum bronze is the step of preparing high-density nano-twinned high-performance nickel-aluminum bronze alloy plate as raw material as follows:

[0034] Step 1, high-temperature solution treatment: the as-cast nickel-aluminum-bronze alloy with an initial thickness of 30mm is placed in a heat treatment furnace at 930°C for 1 hour, and the heating medium is air. Obtain a homogeneous first semi-finished sheet, the resulting structure is Cu 3 Al-based β-phase solid solution and a small amount of fine k-precipitated phase;

[0035] Step 2, strong deformation symmetrical continuous hot rolling: the first semi-finished plate obtained after step 1 solution treatment is warmed in the air for 15 seconds, and then sent to a rolling mill for strong deformation symmetrical continuous hot rolling. The total reduction of symmetrical rolling is 24mm, which is divided into three passes, and the reductions of each pass are 15mm, 6mm and 3mm respectively. The...

Embodiment 2

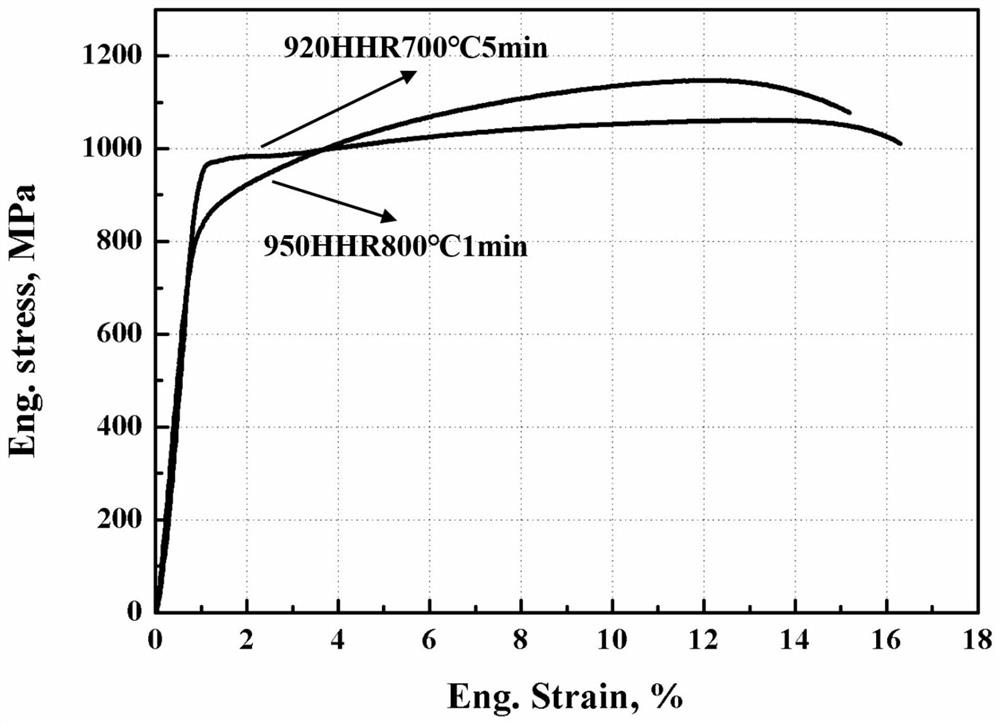

[0039] The steps of preparing a high-density nano-twinned high-performance nickel-aluminum-bronze alloy sheet for corrosion-resistant working conditions are as follows:

[0040] Step 1, high-temperature solution treatment: place the as-cast nickel-aluminum-bronze alloy with an initial thickness of 60 mm in a heat treatment furnace at 950° C. for 40 minutes, and the heating medium is air. Obtain a homogeneous first semi-finished sheet, the resulting structure is Cu 3 Al-based β-phase solid solution;

[0041] Step 2, strong deformation symmetrical continuous hot rolling: the first semi-finished plate obtained after step 1 solution treatment is warmed in the air for 20 seconds, and then sent to a rolling mill for strong deformation symmetrical continuous hot rolling. The total reduction of symmetrical rolling is 48mm, which is divided into three passes, and the reductions of each pass are 30mm, 12mm and 6mm respectively. The initial temperature of the roll is room temperature, ...

Embodiment 3

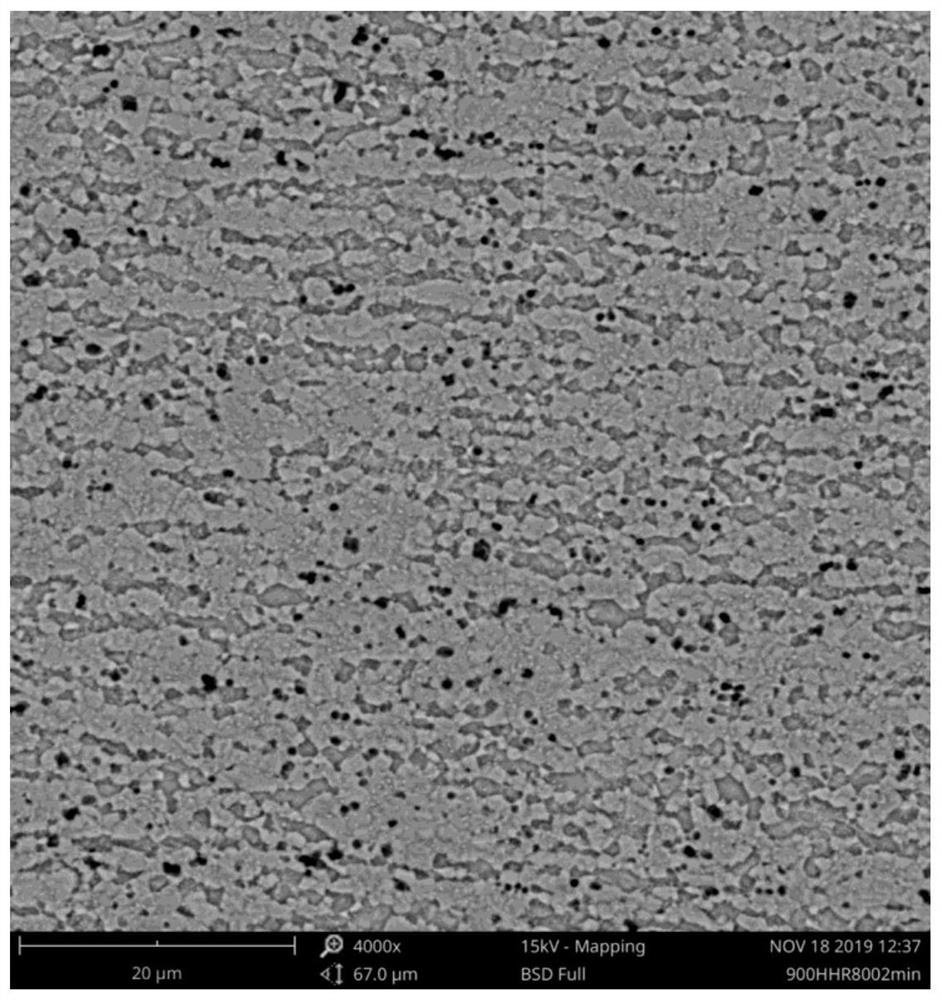

[0045] A method for preparing a high-density nano-twinned high-performance nickel-aluminum-bronze alloy plate, the steps of which are basically the same as in Example 2, except that the time for the medium-temperature short-term heat treatment in step 4 is adjusted to 2.5 minutes. The tensile strength of the obtained board exceeds 1020MPa, the yield strength exceeds 890MPa, and the elongation at break exceeds 15%. The TEM microstructure of the high-density nanotwins obtained by the plate is shown in the attached figure 2 shown in .

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com