Device and method for measuring content of magnetic foreign matters in aluminum oxide

A measuring device, alumina technology, applied in the direction of using material absorption and weighing, etc., can solve the problems of poor adsorption efficiency, safety hazards, expensive equipment, etc., to achieve the effect of promoting full contact, improving adsorption effect, and eliminating adsorption blind spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

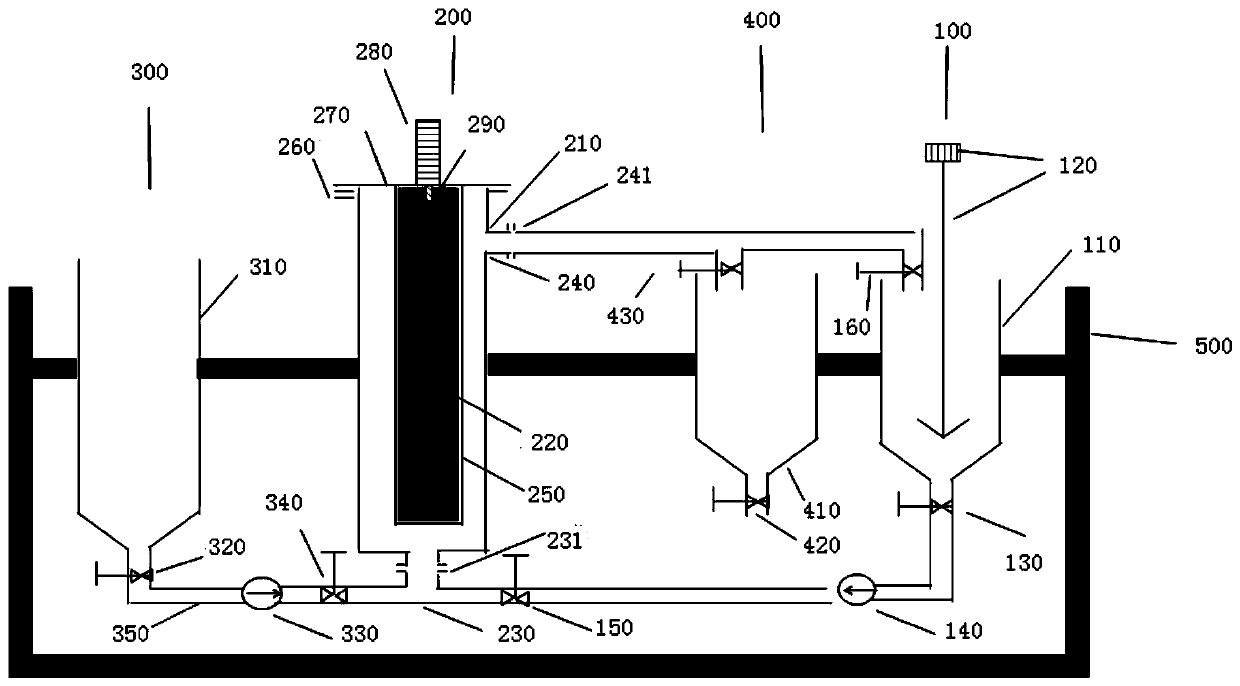

[0042] (1) Slurry: When the ball valves of the equipment are closed, place 5kg of pure water in a 10L conical barrel 110, turn on the electric stirring device 120, add 5Kg of aluminum oxide for lithium battery diaphragm during the stirring process, and stir for 10 minutes.

[0043] (2) Enrichment of magnetic substances: After the slurrying equipment is stirred for 10 minutes, the ball valve 130, the material pump 140, the ball valve 150, and the ball valve 160 are opened, and the slurry circulates between the slurrying equipment 100 and the magnetic substance adsorption equipment 200. After 30min, close material pump 140 and ball valve 130, ball valve 150, ball valve 160.

[0044] (3) Pure water washing: pure water is placed in a conical bucket 310 with a volume of 10 L, and the ball valve 320, ball valve 340, water pump 330, and ball valve 430 are opened in turn, and then the pure water in the conical bucket 310 passes through the water pump 330, the magnetic substance The ad...

specific Embodiment approach 2

[0047] (1) Slurrying: With each ball valve of the equipment closed, place 5kg of pure water in a 10L conical barrel 110, turn on the electric stirring device 120, add 5Kg of ordinary alumina during the stirring process, and stir for 10 minutes.

[0048] (2) Enrichment of magnetic substances: After the slurrying equipment is stirred for 10 minutes, the ball valve 130, the material pump 140, the ball valve 150, and the ball valve 160 are opened, and the slurry circulates between the slurrying equipment 100 and the magnetic substance adsorption equipment 200. After 30min, close material pump 140 and ball valve 130, ball valve 150, ball valve 160.

[0049] (3) Pure water washing: pure water is placed in a conical bucket 310 with a volume of 10 L, and the ball valve 320, ball valve 340, water pump 330, and ball valve 430 are opened in turn, and then the pure water in the conical bucket 310 passes through the water pump 330, the magnetic substance The adsorption device 200 enters th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetism | aaaaa | aaaaa |

| magnetism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com