Continuous casting crystallizer function protection material special for ESP high-carbon steel

A technology of continuous casting mold and protective material, applied in the field of metallurgical auxiliary materials, can solve the problems of inapplicable ESP high carbon steel, uneven inflow of slag film, slag inclusion, etc. Effect of layer thickness and crystallization rate increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be described in detail below in conjunction with specific embodiments.

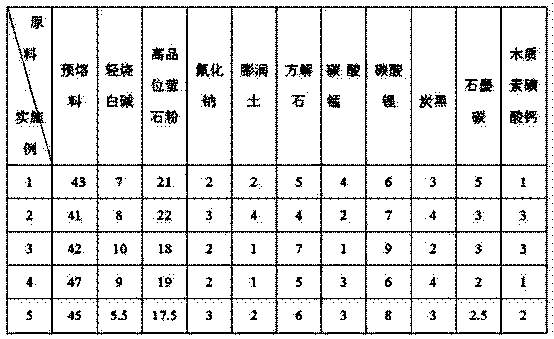

[0023] The present invention is described in detail through the following 5 embodiments. The ESP high-carbon steel special continuous casting crystallizer functional protection material provided by the present invention is displayed in tabular form, and the ESP high-carbon steel special continuous casting mold functional protection provided by 7 embodiments The raw materials and their weight percentages of the materials are shown in Table 1.

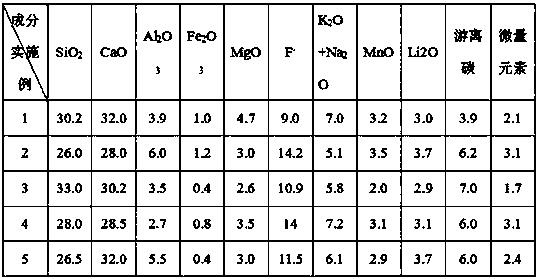

[0024] Table 2 shows the chemical components and weight percentages of the functional protection materials for continuous casting molds for ESP high carbon steel provided in Examples 1-5.

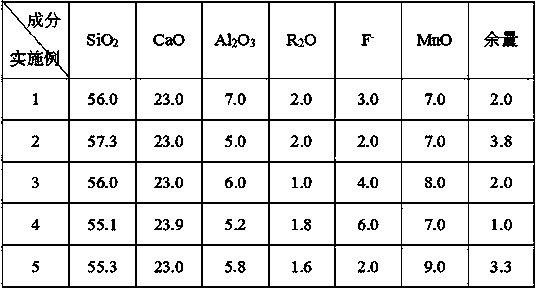

[0025] The chemical composition and weight percentage of the premelt of the special continuous casting mold functional protection material for ESP high carbon steel provided in Examples 1-5 are shown in Table 3.

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com