Application of graphene fiber in mid-infrared photoelectric detection

A technology of graphene fiber and infrared light, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as low density and applicability of microscopic detection devices, and achieve good flexibility, wide application prospects, and simple and convenient operation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A flexible mid-infrared detector based on graphene fibers, comprising the following processes:

[0019] (1) Using the dispersion of graphene oxide as the raw material (Golene Technology), using wet spinning technology to prepare solid cylindrical fibers with a diameter of 20 microns, heat reduction at 2000°C for 10 minutes, the measured carbon-oxygen ratio is 10.1.

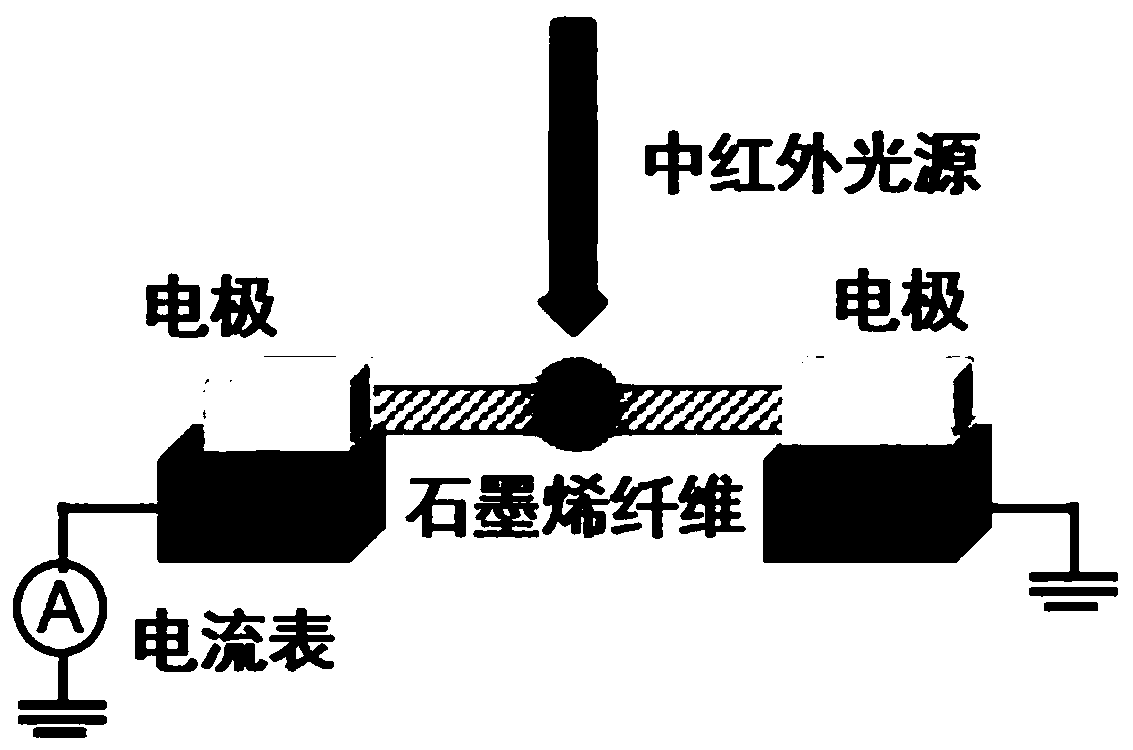

[0020] (2) Graphene fibers with a length of 1 cm were fixed between copper electrodes and assembled as figure 1 In the detector, a dark current of 20mA is input to the graphene fiber through two electrodes.

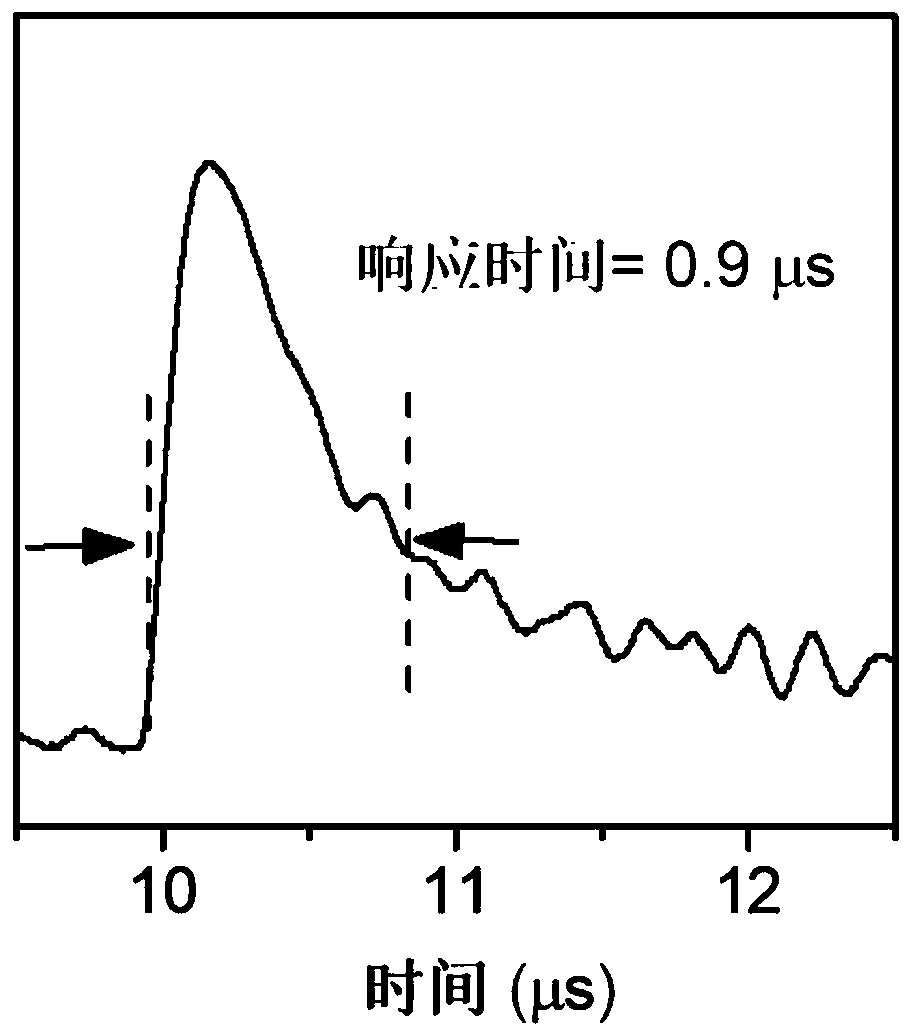

[0021] (3) Under the working pressure environment of 10mbar and the working temperature environment of 400K, the wavelength is 3 microns and the power is 5mW / cm 2 The mid-infrared light illuminates the graphene fiber, and the current signal is collected through two electrodes. The current of the device produces a fast response, with a rising edge of 100 nanoseconds, a falling edge of 2 microseconds,...

Embodiment 2

[0023] A flexible mid-infrared detector based on graphene fibers, comprising the following processes:

[0024] (1) Using the dispersion of graphene oxide as the raw material (Golene Technology), using wet spinning technology to prepare solid cylindrical graphene fibers with a diameter of 32 microns, heat reduction at 2000°C for 10 minutes, and measure carbon and oxygen The ratio is 11.

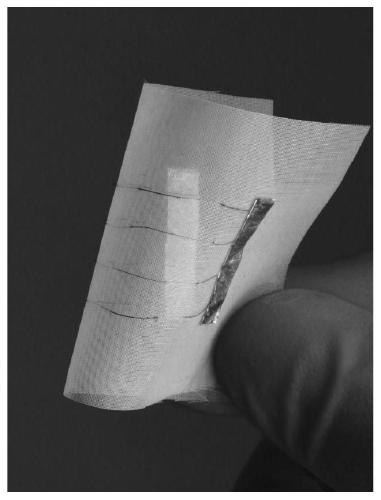

[0025] (2) Prepare the graphene fiber as above image 3 said weaving.

[0026] (3) Set between copper electrodes on both sides of the woven fabric, the distance between the two electrodes is 3cm, and a dark current of 13mA is input.

[0027] (4) The working pressure environment is 1013mbar; the working temperature environment is 30K environment, the wavelength is 5.5 microns, and the power is 7mW / cm 2 The mid-infrared light illuminates the graphene fiber, and the current signal is collected through two electrodes. The device's current response is fast, with a rising edge of 130 nanoseconds...

Embodiment 3

[0030] A flexible mid-infrared detector based on graphene fibers, comprising the following processes:

[0031] (1) Using the dispersion of graphene oxide as the raw material (Golene Technology), using wet spinning technology to prepare solid cylindrical fibers with a diameter of 45 microns, heat reduction at 2000°C for 20 minutes, the measured carbon-oxygen ratio is 10.4.

[0032] (2) A graphene fiber with a length of 10 cm was fixed between copper electrodes, and a dark current of 3 mA was input.

[0033] (3) In the working air pressure environment of 1013mbar; working temperature environment of 400K environment, the use of power is 9mW / cm 2 , the graphene fiber is irradiated with mid-infrared light with a wavelength of 3 microns, and the current signal is collected through two electrodes. The device's current response is fast, with a rising edge of 140 nanoseconds, a falling edge of 4.5 microseconds, and a response time of 1.3 microseconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com