Method for preparing graphene electromagnetic shielding material

An electromagnetic shielding material, graphene technology, applied in the direction of graphene, magnetic/electric field shielding, chemical instruments and methods, etc., can solve the problems of limited electromagnetic shielding performance, high density of membrane airgel, and limited release of gas, etc., to achieve Excellent shielding effect, low density, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

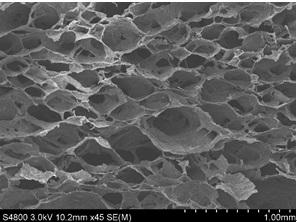

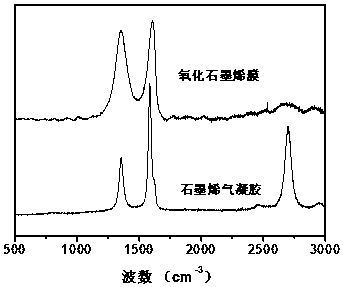

Embodiment 1

[0024] A suspension of graphene oxide with a size distribution between 20-30um, a carbon-to-oxygen ratio of 2.5, and a concentration of 5mg / ml (purchased from Hangzhou Gaoxi Technology Co., Ltd.) was prepared by scraping to form a film with a thickness of about 20um. The graphene oxide membrane material was cut into a disc, and then placed in 85% hydrazine hydrate solution. After one hour, a graphene airgel with a height of about 8.1mm was obtained, and the hair was replaced with ethanol. Foam solution, and then dried at 60°C to remove ethanol, after 1 hour of high temperature treatment at 1600°C, a density of 3 mg / cm 3 The graphene-based airgel, I D / I G It is 0.2, and its electromagnetic shielding effectiveness is 110dB at 5mm.

Embodiment 2

[0026] A suspension of graphene oxide with a size distribution between 80-100um, a carbon-to-oxygen ratio of 2.35, and a concentration of 10mg / ml (purchased from Hangzhou Gaoxi Technology Co., Ltd.) was prepared by scraping to form a film with a thickness of about 50um. The graphene oxide membrane material is cut into a disc, and the graphene oxide membrane material is placed in 100mg / ml ammonium bicarbonate aqueous solution. After a period of time, a graphene airgel with a height of about 12.6mm is obtained. Materials, replace the blowing agent solution with isopropanol, and then dry at 60°C to remove isopropanol. After 1 hour of high temperature treatment at 1600°C, a density of 5 mg / cm is obtained. 3 Graphene-based aerogels, I D / I G It is 0.15, and its electromagnetic shielding effectiveness is 70dB at 5mm.

Embodiment 3

[0028] A suspension of graphene oxide with a size distribution between 100-200um, a carbon-to-oxygen ratio of 2.14, and a concentration of 10mg / ml (purchased from Hangzhou Gaoxi Technology Co., Ltd.) was prepared by suction filtration to obtain a 30um thick graphene oxide suspension. Graphene membrane material, cut it into a disc, place the graphene oxide membrane material in 100mg / ml ammonium bicarbonate aqueous solution, and after a period of time, a graphene airgel material with a height of about 8.5mm is obtained. Replace the blowing agent solution with isopropanol, and then dry at 60°C to remove isopropanol. After 1 hour of high-temperature treatment at 1000°C, a density of 5.3 mg / cm was obtained. 3 Graphene-based aerogels, I D / I G It is 0.1, and its electromagnetic shielding effectiveness is 102dB at 5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com