A method for preparing nitrogen-doped carbon and nitrogen-containing heterocycle by using plasma

A technology of plasma and nitrogen heterocycle, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of low selectivity of nitrogen-containing products, lower biomass utilization rate, and affect high-value utilization, etc., to achieve Achieve high-value utilization, improve utilization, reduce energy consumption and thermal corrosion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

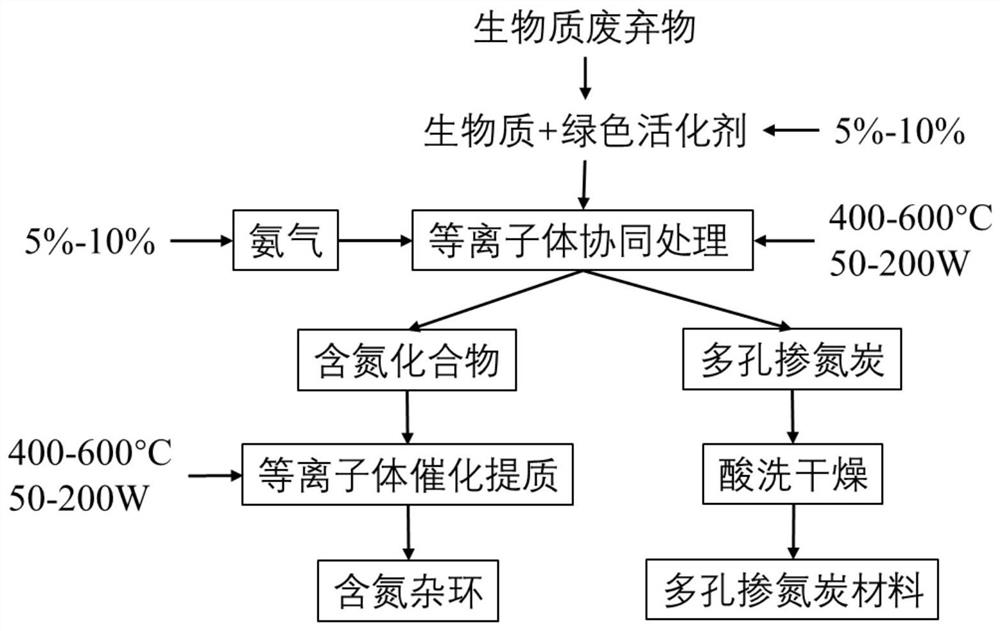

[0042] The embodiment of the present invention describes a method for preparing nitrogen-doped carbon and nitrogen-containing heterocycles by using plasma, and the method specifically includes the following steps:

[0043] S1: Combine the crushed and dried bamboo with a small amount of green activator CH 3 COOK for full mechanical mixing, drying temperature is 105°C, drying time is 24h, CH 3 COOK quality accounts for 5% of bamboo quality, obtains reaction raw material,

[0044] S2: Put the mixture (2g) of step S1 into the first stage of dielectric barrier discharge plasma reactor, the reaction temperature is 400°C, the plasma power is 50W, and a certain proportion of ammonia gas is introduced, and the total gas flow rate is 500mL / min, the proportion of ammonia to the total gas (ammonia and argon) is 5%, the plasma promotes the decomposition of ammonia and biomass, strengthens the synergy between ammonia and green activators, promotes the full activation of biomass and nitrog...

Embodiment 2

[0050] S1: Combine the crushed and dried bamboo with a small amount of green activator CH 3 COOK for full mechanical mixing, drying temperature is 105°C, drying time is 24h, CH 3 COOK quality accounts for 8% of bamboo quality, obtains reaction raw material,

[0051] S2: Put the mixture (2g) of step S1 into the first stage of the dielectric barrier discharge plasma reactor, the reaction temperature is 500°C, the plasma power is 100W, and a certain proportion of ammonia gas is introduced, and the total gas flow rate is 500mL / min, the proportion of ammonia to the total gas (ammonia and argon) is 8%, the plasma promotes the decomposition of ammonia and biomass, strengthens the synergy between ammonia and green activators, promotes the full activation of biomass and nitrogen doping, and the reaction time for 30min,

[0052] S3: Pass the pyrolysis volatiles obtained in step S2 into the second stage of the dielectric barrier discharge plasma reactor. Under the action of ZSM-5 cata...

Embodiment 3

[0057] S1: Combine the crushed and dried bamboo with a small amount of green activator CH 3 COOK for full mechanical mixing, drying temperature is 105°C, drying time is 24h, CH 3 COOK quality accounts for 10% of bamboo quality, obtains reaction raw material,

[0058] S2: Put the mixture (2g) of step S1 into the first stage of dielectric barrier discharge plasma reactor, the reaction temperature is 600°C, the plasma power is 200W, and a certain proportion of ammonia gas is introduced, and the total gas flow rate is 500mL / min, the proportion of ammonia to the total gas (ammonia and argon) is 10%, the plasma promotes the decomposition of ammonia and biomass, strengthens the synergy between ammonia and green activators, promotes the full activation of biomass and nitrogen doping, and the reaction time for 60min,

[0059] S3: Pass the pyrolysis volatiles obtained in step S2 into the second stage of the dielectric barrier discharge plasma reactor. Under the action of ZSM-5 cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com