Preparation method of mixed grinding of steel slag-slag-gypsum composite cementitious material

A technology of composite cementitious material and mixed powder, which is applied in cement production and other directions, can solve the problems such as not involving the comprehensive treatment of cementitious materials, and the comprehensive utilization rate of steel slag is less than 40%, so as to achieve comprehensive utilization value, fineness and specific surface area. Stable and simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

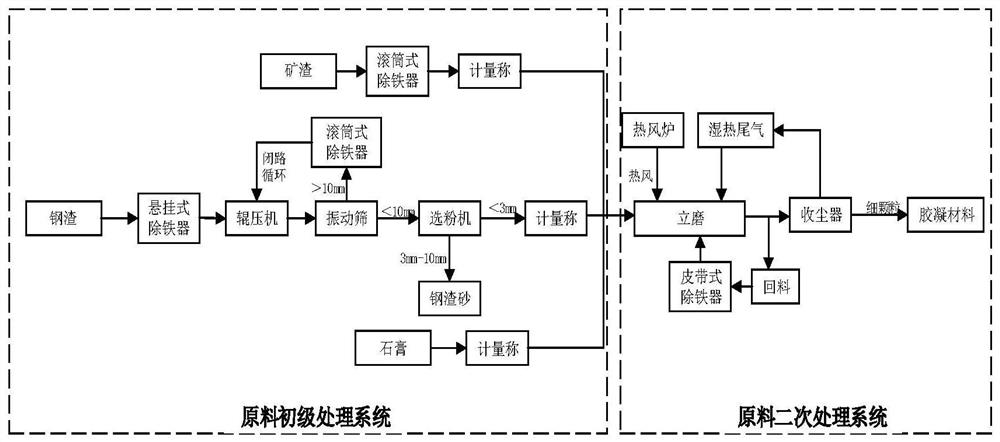

[0037] This embodiment provides a method for mixing and grinding steel slag-slag-gypsum composite cementitious material, comprising the following steps:

[0038] (1) Preparation of steel slag particles

[0039]Primary crushing and pre-removal of steel slag raw materials: The raw material of converter steel slag is fed, and pre-removed by hanging iron remover. The steel slag after pre-removed iron enters the roller press for primary crushing, and then enters the vibrating screen for screening. After sieving, coarse particles I and fine particles I are produced. The particle size of coarse particles I is 15mm, and the particle size of fine particles I is 10mm. Fine particles I form steel slag sand and steel slag grains after powder selection by powder classifier, the granularity of steel slag sand is 5mm, and the granularity of steel slag grains is 2.7mm.

[0040] (2) Pretreatment of slag

[0041] The blast furnace water-quenched slag raw material is fed, and iron is removed i...

Embodiment 2

[0046] This embodiment provides a method for mixing and grinding steel slag-slag-gypsum composite cementitious material, comprising the following steps:

[0047] (1) Preparation of steel slag particles

[0048] Primary crushing and pre-removal of steel slag raw materials: Feed the raw material of steel slag from electric furnace, and pre-remove iron with a hanging iron remover. After sieving, coarse particles I and fine particles I are produced, the particle size of coarse particles I is 10mm, and the particle size of fine particles I is 5mm; coarse particles I return to the roller press after iron removal by the drum type iron remover to continue crushing, forming a closed loop Fine particles I form steel slag sand and steel slag grains after powder selection by powder classifier, the granularity of steel slag sand is 3mm, and the granularity of steel slag grains is 2mm.

[0049] (2) Pretreatment of slag

[0050] The blast furnace water-quenched slag raw material is fed, an...

experiment example

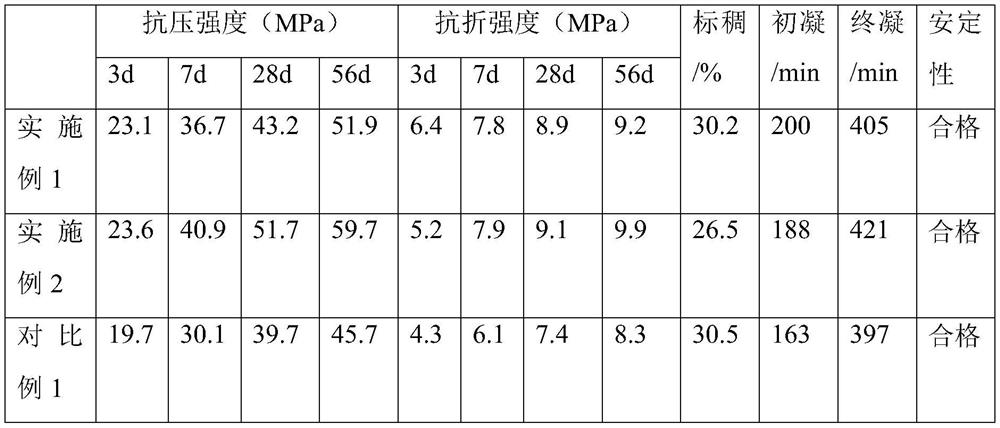

[0057] (1) Comparing the gelled material prepared by Comparative Example 2 and Comparative Example 1, the 28d activity of the gelled material of Comparative Example 1 can only reach 93% of that of Example 2, and the activity is low; the grinding process of Comparative Example 1 The energy consumption is 10% higher than that of Example 2, but the production capacity is only 85% of that of Example 2.

[0058] (2) The cementitious materials prepared in Example 1-2 and Comparative Example 1 are respectively prepared into mortar test pieces according to the water-to-binder ratio of 0.32, and the amount of water reducer is based on the fluidity of the mortar at 180-220mm. The material stability test is carried out according to GB / T 1346-2011 "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Method". The stability test adopts two methods of test cake method and Rayleigh method, and the stability is in line with the national standard. The parameter comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com