Preparation method of binaphthyl-based network type polyimide resin and film and application of binaphthyl-based network type polyimide resin and film in gas separation

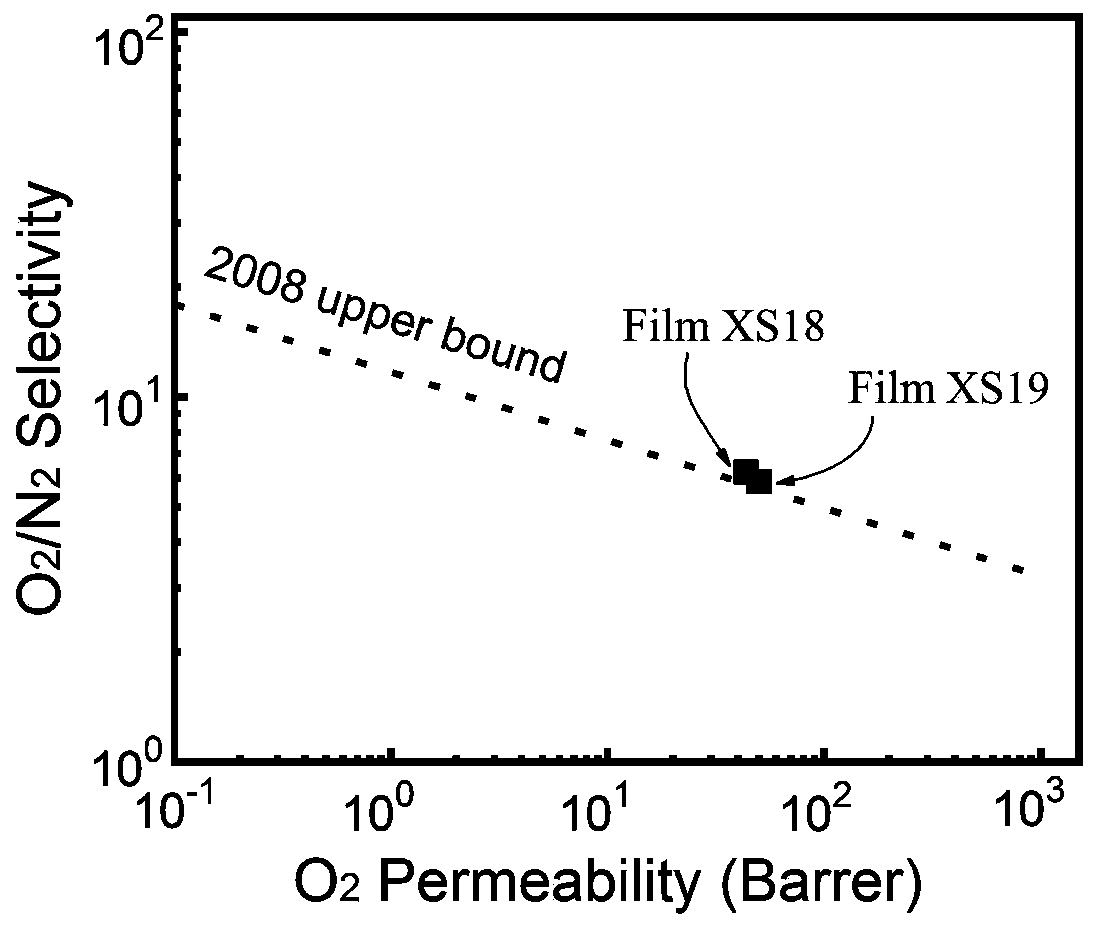

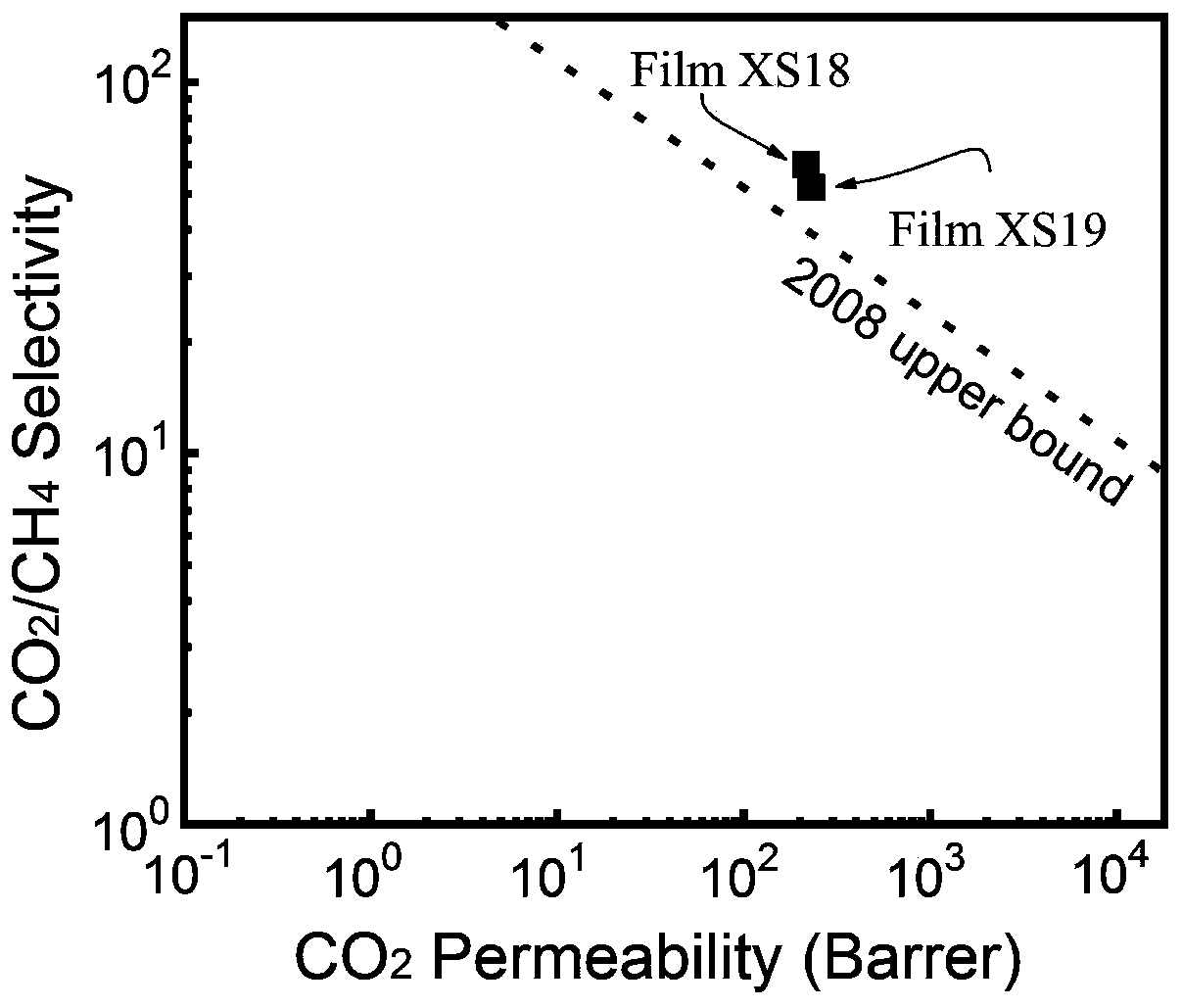

A technology of polyimide resin and binaphthalene, which is applied in the field of synthesis and film preparation, can solve the problems of difficult to meet the requirements of gas separation, difficult to control the pore size of polymer micropores, etc., and achieve excellent gas permeability and selectivity, The effect of preventing physical collapse of pores and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

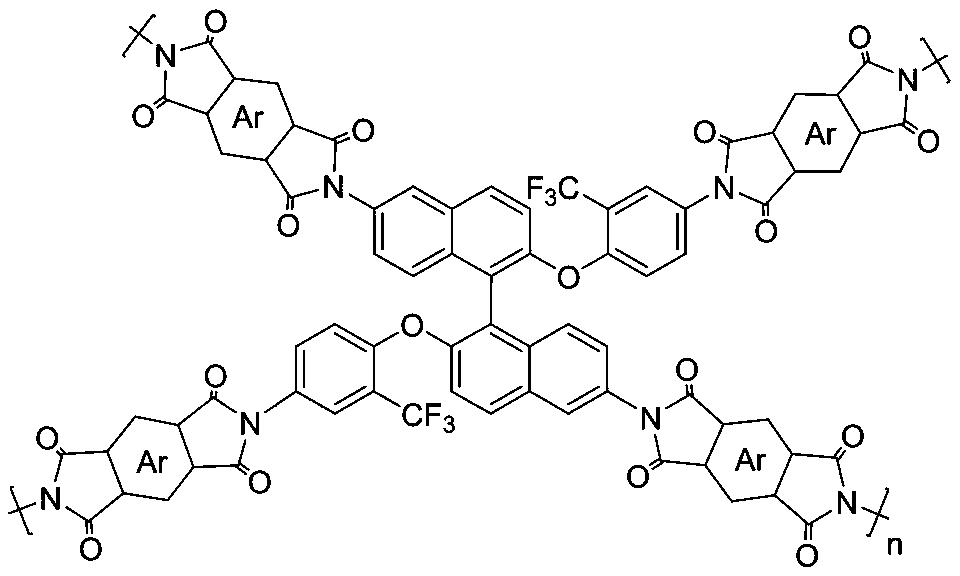

[0032] The preparation method of the gas separation membrane of the present invention mainly comprises the following steps: the preparation of the binaphthyl tetramine monomer, the preparation of the binaphthyl network polyamic acid resin and the binaphthyl network polyimide resin Film preparation. Concrete preparation steps are as follows:

[0033] (1) Preparation of 7,7'-dinitro-1,1'-binaphthol (compound 1)

[0034] Prepare a single-necked round bottom flask, add a certain amount of acetic acid and 1,1'-binaphthol, and stir vigorously for 10 minutes. Then fuming nitric acid (98%) was slowly added dropwise to the reaction solution, stirred at room temperature for 1 h, during which the color of the solution changed from white to black, and finally to green. The mixture was poured into ice water and stirred for 10 min, filtered and dried to obtain compound 1.

[0035] (2) Preparation of tetranitrobinaphthalene (compound 2)

[0036] Compound 1, K 2 CO 3 and anhydrous DMF w...

Embodiment 1

[0043] Embodiment 1: Preparation of binaphthyl network polyimide resin XS18

[0044] (1) Preparation of 7,7'-dinitro-1,1'-binaphthol (compound 1)

[0045] Add 1,1'-binaphthol (1.0g, 3.49mmol) and acetic acid (15mL) into a 25ml single-necked round bottom flask, stir at room temperature for 10min, then slowly add fuming nitric acid dropwise to the solution at 0°C (98%, 0.62 mL, 15.24 mmol). The resulting mixture was then stirred at room temperature for 1 h, during which time the solution color changed from white to black and finally green. The mixture was poured into ice water (500ml) and stirred for 10min, filtered and dried to obtain a green powder (compound 1) with a yield of 78%.

[0046] (2) Preparation of tetranitrobinaphthalene (compound 2)

[0047] Add compound 1 (7.00g, 18.61mmol), K 2 CO 3 (3.85 g, 27.92 mmol) and anhydrous DMF (200 mL), stirred at room temperature for 30 minutes until a homogeneous solution was obtained. 2-Chloro-5-nitrobenzotrifluoride (8.79 g,...

Embodiment 2

[0052] Example 2: Preparation of Bininaphthyl Network Polyimide Resin XS19

[0053] (1) Preparation of 7,7'-dinitro-1,1'-binaphthol (compound 1)

[0054] Add 1,1'-binaphthol (1.0g, 3.49mmol) and acetic acid (15mL) into a 25ml single-necked round bottom flask, stir at room temperature for 10min, then slowly add fuming nitric acid dropwise to the solution at 0°C (98%, 0.62 mL, 15.24 mmol). The resulting mixture was then stirred at room temperature for 1 h, during which time the solution color changed from white to black and finally green. The mixture was poured into ice water (500ml) and stirred for 10min, filtered and dried to obtain a green powder (compound 1) with a yield of 78%.

[0055] (2) Preparation of tetranitrobinaphthalene (compound 2)

[0056] Add compound 1 (7.00g, 18.61mmol), K 2 CO 3 (3.85 g, 27.92 mmol) and anhydrous DMF (200 mL), stirred at room temperature for 30 minutes until a homogeneous solution was obtained. 2-Chloro-5-nitrobenzotrifluoride (8.79 g, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability coefficient | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap