Degradable EVA foam material and preparation method thereof

A foaming material, ethylene technology, applied in the field of foaming materials, can solve the problems of poor mechanical strength and other comprehensive use performance, poor anti-slip effect, poor wear resistance, etc., to achieve good anti-slip effect, high elasticity, and improved quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A kind of degradable EVA foaming material, is made of the raw material that comprises following parts by weight:

[0056] 35-45 parts of ethylene-vinyl acetate copolymer,

[0057] 15-20 parts of POE elastomer,

[0058] 8 to 12 parts of rubber,

[0059] 6-10 parts of bio-based polypentamethylene adipate polymer,

[0060] 20-30 parts of degradable organic matter,

[0061] 1 to 1.5 parts of stearic acid,

[0062] 1 to 1.2 parts of zinc oxide,

[0063] 1 to 1.5 parts of peroxide,

[0064] 1-5 parts of AC blowing agent.

[0065] In this embodiment, the degradable organic matter is preferably tapioca flour or cornstarch.

[0066] In this embodiment, the vinyl acetate content in the ethylene-vinyl acetate copolymer is preferably 32.5-36.5%.

[0067] In this embodiment, the POE elastomer is preferably a mixture of ethylene-octene copolymer and ethylene-hexene copolymer.

[0068] In this embodiment, the bio-based polypentamethylene adipate polymer is preferably made of ...

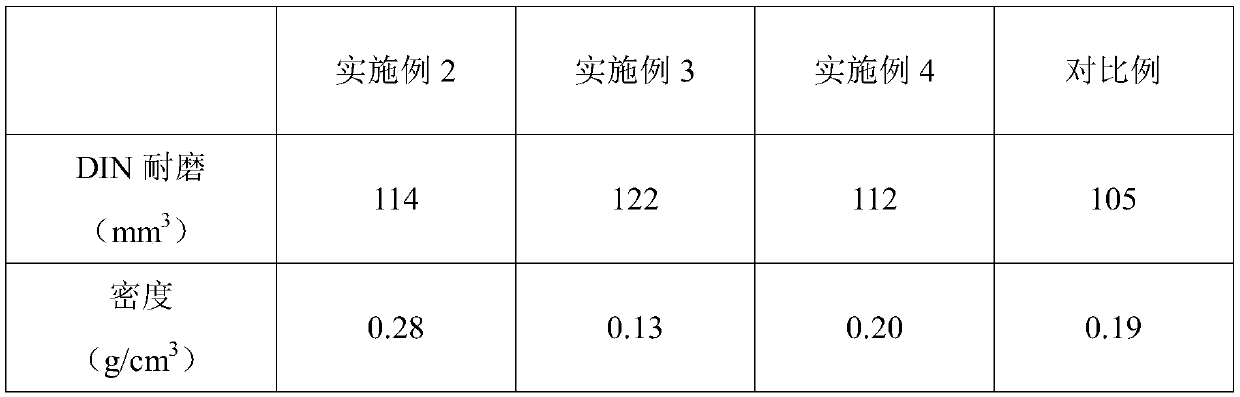

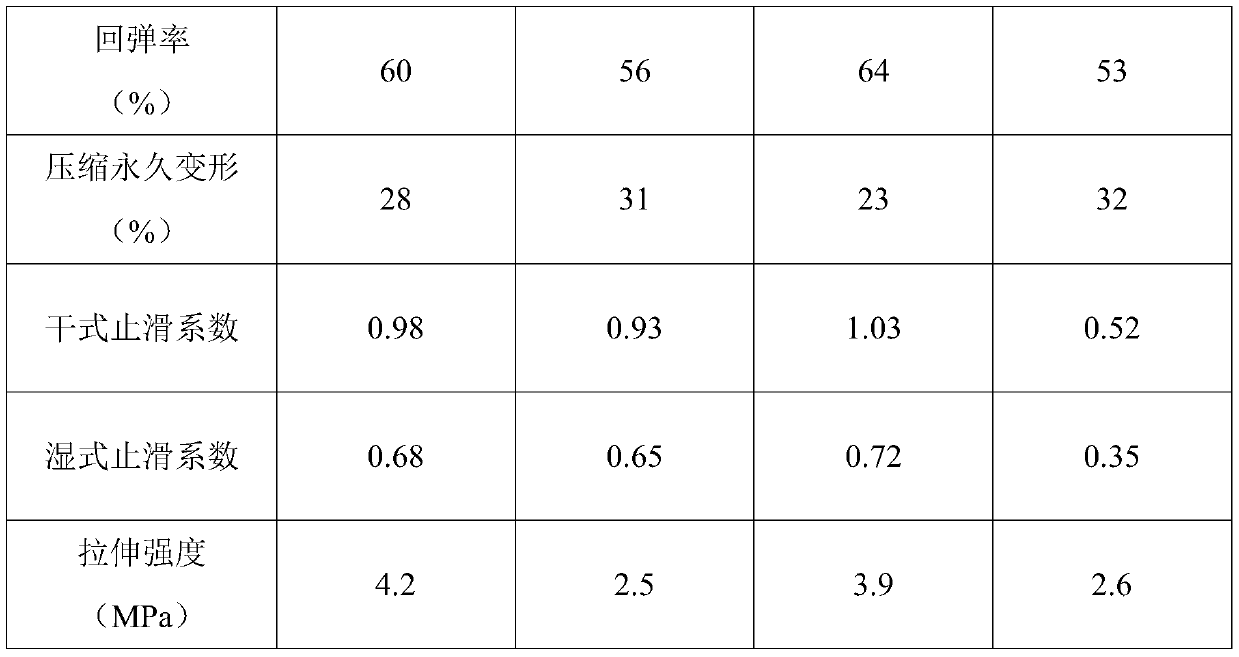

Embodiment 2

[0088] A kind of degradable EVA foaming material, is made of the raw material that comprises following parts by weight:

[0089] 35 parts of ethylene-vinyl acetate copolymer,

[0090] POE elastomer 15 parts,

[0091] 8 parts of rubber,

[0092] Bio-based polypentamethylene adipate polymer 6 parts,

[0093] 20 parts of degradable organic matter,

[0094] 1 part stearic acid,

[0096] 1 part peroxide,

[0097] 1 part of AC foaming agent.

[0098] In this embodiment, the degradable organic matter is tapioca flour or corn starch.

[0099] In this embodiment, the content of vinyl acetate in the ethylene-vinyl acetate copolymer is 32.5%.

[0100] In this embodiment, the POE elastomer is a mixture of ethylene-octene copolymer and ethylene-hexene copolymer.

[0101] In this example, the bio-based polypentamethylene adipate polymer is made from petroleum-based adipic acid and bio-based pentamethylene adipate.

[0102] In this embodiment, the peroxi...

Embodiment 3

[0111] A kind of degradable EVA foaming material, is made of the raw material that comprises following parts by weight:

[0112] 45 parts of ethylene-vinyl acetate copolymer,

[0113] POE elastomer 20 parts,

[0114] 12 parts of rubber,

[0115] 10 parts of bio-based polypentamethylene adipate polymer,

[0116] 30 parts of degradable organic matter,

[0117] 1.5 parts of stearic acid,

[0118] Zinc oxide 1.2 parts,

[0119] 1.5 parts peroxide,

[0120] AC blowing agent 5 parts.

[0121] In this embodiment, the degradable organic matter is tapioca flour or corn starch.

[0122] In this embodiment, the content of vinyl acetate in the ethylene-vinyl acetate copolymer is 36.5%.

[0123] In this embodiment, the POE elastomer is a mixture of ethylene-octene copolymer and ethylene-hexene copolymer.

[0124] In this example, the bio-based polypentamethylene adipate polymer is made from petroleum-based adipic acid and bio-based pentamethylene adipate.

[0125] In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com