Multifunctional self-reinforced type double-component filament electrostatic filter material as well as preparation method and application thereof

A two-component, enhanced technology, applied in the field of non-woven fabrics, can solve the problems of unfavorable post lamination, discount processing, poor fabric style aesthetics, small rebound deformation, etc., to achieve stable, reliable and unique product performance The beauty of filament and the effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The skin layer polymer in component A is PE masterbatch, with a melting point of 130-135°C. At the same time, 1.5wt% of the total weight of component A is mixed into component A with a functional medium with electricity storage function; the core layer of component B is The polymer is PET polyester chips with a melting point of 255-265°C, and 5 wt% of the total weight of component B is mixed with a functional medium with antibacterial and antifungal effects. The mass ratio of component A and component B is 50%:50%.

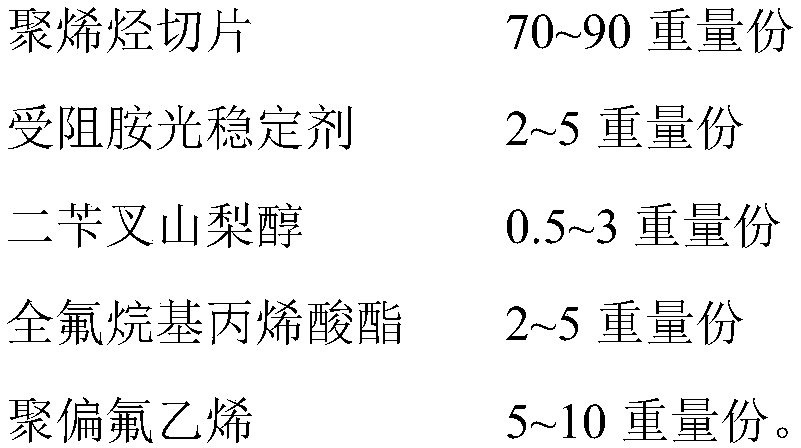

[0065] In this embodiment, the functional medium with electricity storage function includes the following raw material components and parts by weight:

[0066]

[0067] The functional medium with electricity storage function is obtained by blending and granulating various raw material components.

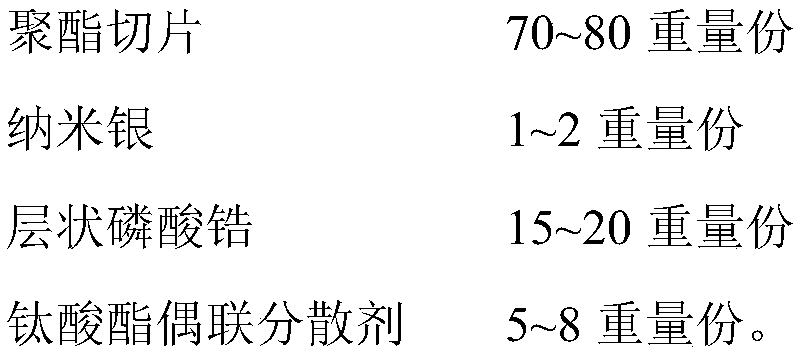

[0068] In this embodiment, the raw material components of the functional medium with antibacterial and antifungal effects include and parts by weight are as ...

Embodiment 2

[0079] The skin layer polymer in component A is PE masterbatch with a melting point of 130-135°C. At the same time, 1.0wt% of the total weight of component A is mixed into component A with a functional medium with electricity storage function; the core layer of component B is The polymer is PET polyester chips with a melting point of 255-265°C; a melting point of 255-265°C is mixed with a functional medium with antibacterial and anti-mildew effects accounting for 5wt% of the total weight of component B. The mass ratio of component A and component B is 40%:60%. The manufacturing process is the same as in Example 1.

[0080] In this embodiment, the functional medium with electricity storage function includes the following raw material components and parts by weight:

[0081]

[0082]

[0083] The functional medium with electricity storage function is obtained by blending and granulating various raw material components.

[0084] In this embodiment, the raw material compon...

Embodiment 3

[0092] The skin layer polymer in component A is PE masterbatch, with a melting point of 130-135°C; at the same time, 1 wt% of the total weight of component A is mixed into component A with a functional medium with electricity storage function; the core layer of component B is The polymer is PET polyester chips with a melting point of 255-265°C. The melting point is 162-165°C, and 5 wt% of the total weight of component B is mixed with a functional medium with antibacterial and antifungal effects. The mass ratio of component A and component B is 40wt%: 60wt%. The manufacturing process is the same as in Example 1.

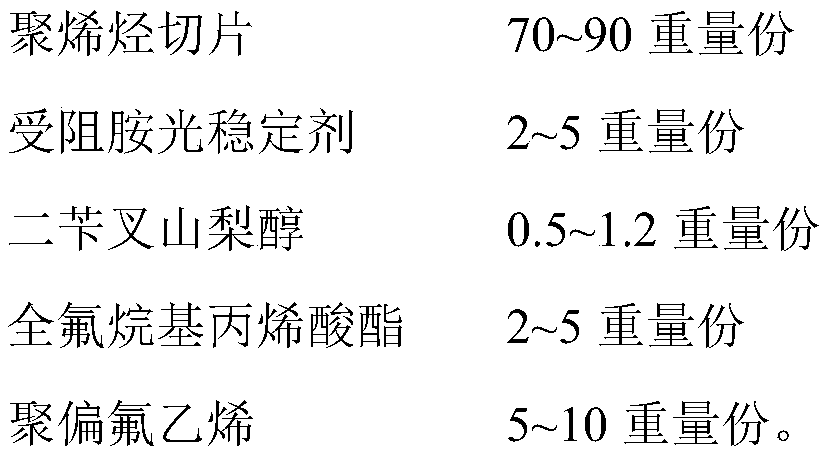

[0093] In this embodiment, the functional medium with electricity storage function includes the following raw material components and parts by weight:

[0094]

[0095]

[0096] In this embodiment, the raw material components of the functional medium with antibacterial and antifungal effects include and parts by weight are as follows:

[0097]

[0098] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com