Synthesis method of 3-n-butyl-1-(3H)-isobenzofuranone

A technology of furanone and isobenzene, applied in the field of medicine, can solve problems such as tedious, unsuitable for industrial production, and complicated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

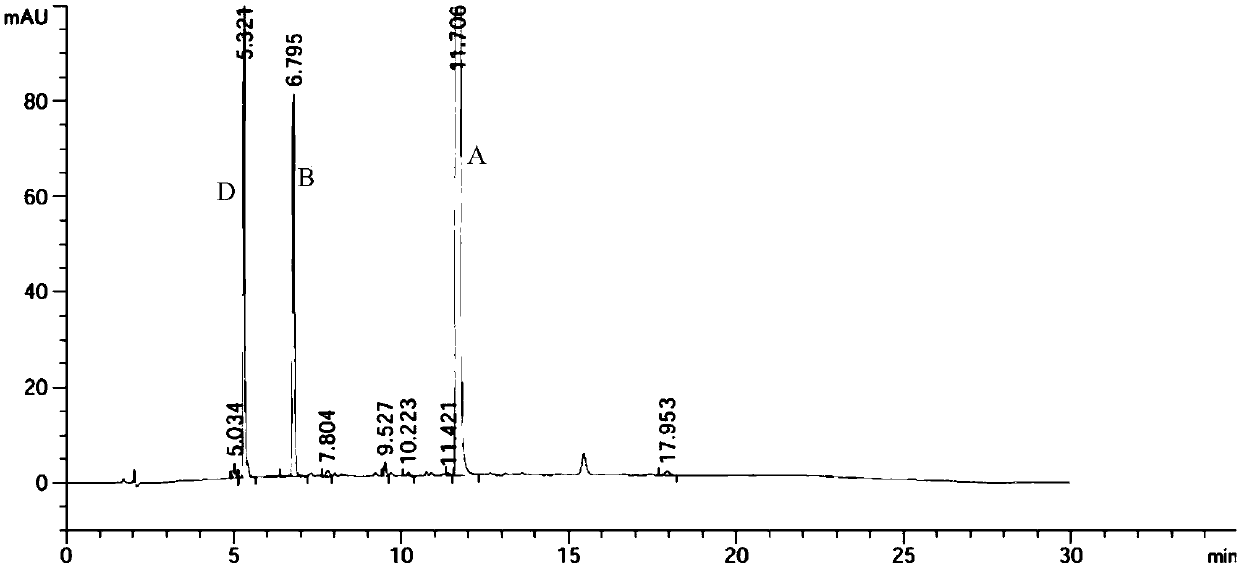

[0044] Example 1: Synthesis of 3-n-butyl-1 (3H)-isobenzofuranone (without additive)

[0045] O-formylbenzoic acid (5.00 g, 33.3 mmol) was dissolved in tetrahydrofuran (20.0 mL) to obtain a tetrahydrofuran solution of o-formylbenzoic acid. Add 2mol / L tetrahydrofuran solution of n-butylmagnesium chloride (36.6ml, 73.3mmol) into a 250mL three-necked flask. After cooling down to -10°C, add the tetrahydrofuran solution of o-formylbenzoic acid dropwise into the tetrahydrofuran solution of n-butylmagnesium chloride, and control the internal temperature at -10-10°C. After dropping, the reaction was continued at 25° C. until the end of the reaction monitored by HPLC. Adjust the pH to 2-3 with 4 mol / L hydrochloric acid, separate the layers, extract the aqueous layer with ethyl acetate (50 mL×2), combine the organic phases, and wash with saturated brine (100 mL). After the organic phase was concentrated, 6.23 g of 3-n-butyl-l(3H)-isobenzofuranone was obtained. The HPLC purity is 87.2%...

Embodiment 2

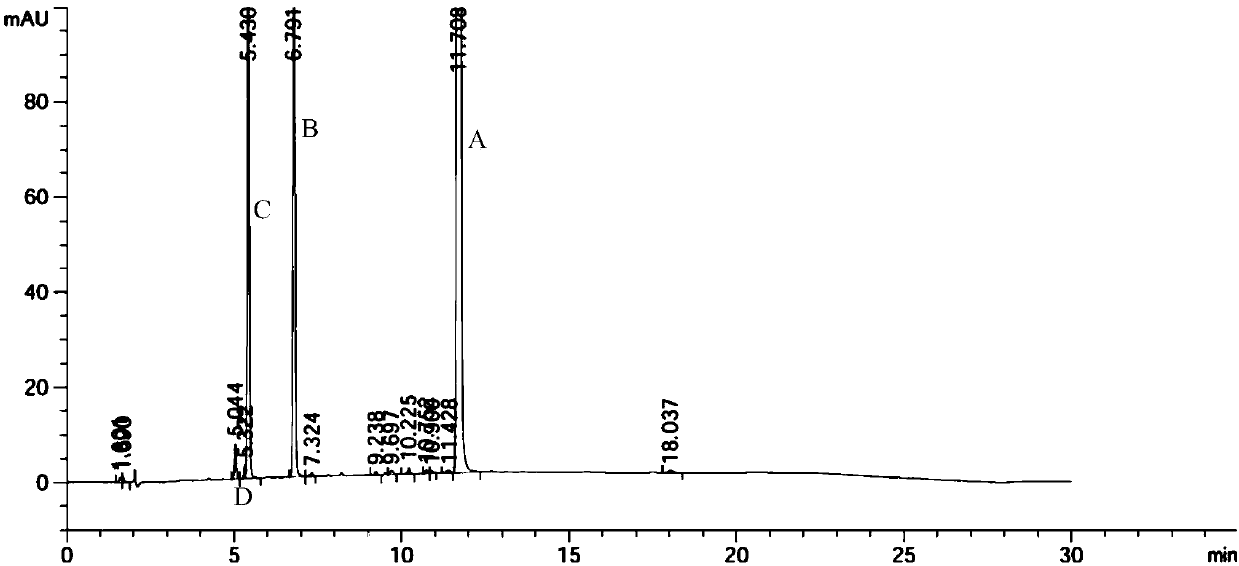

[0046] Example 2: Synthesis of 3-n-butyl-1(3H)-isobenzofuranone (addition of Lewis acid)

[0047] O-formylbenzoic acid (5.00 g, 33.3 mmol) was dissolved in tetrahydrofuran (20.0 mL) to obtain a tetrahydrofuran solution of o-formylbenzoic acid. Add 2mol / L tetrahydrofuran solution of n-butylmagnesium chloride (36.6ml, 73.3mmol) and 0.65g Lewis acid into a 250mL three-necked flask. After cooling down to -10°C, add the tetrahydrofuran solution of o-formylbenzoic acid dropwise into the tetrahydrofuran solution of n-butylmagnesium chloride, and control the internal temperature at -10 to 10°C. After dropping, the reaction was continued at 25° C. until the end of the reaction monitored by HPLC. Adjust the pH to 2-3 with 4 mol / L hydrochloric acid, separate the layers, extract the aqueous layer with ethyl acetate (50 mL×2), combine the organic phases, and wash with saturated brine (100 mL). After concentration of the organic phase, 3-n-butyl-l(3H)-isobenzofuranone was obtained.

[00...

Embodiment 3

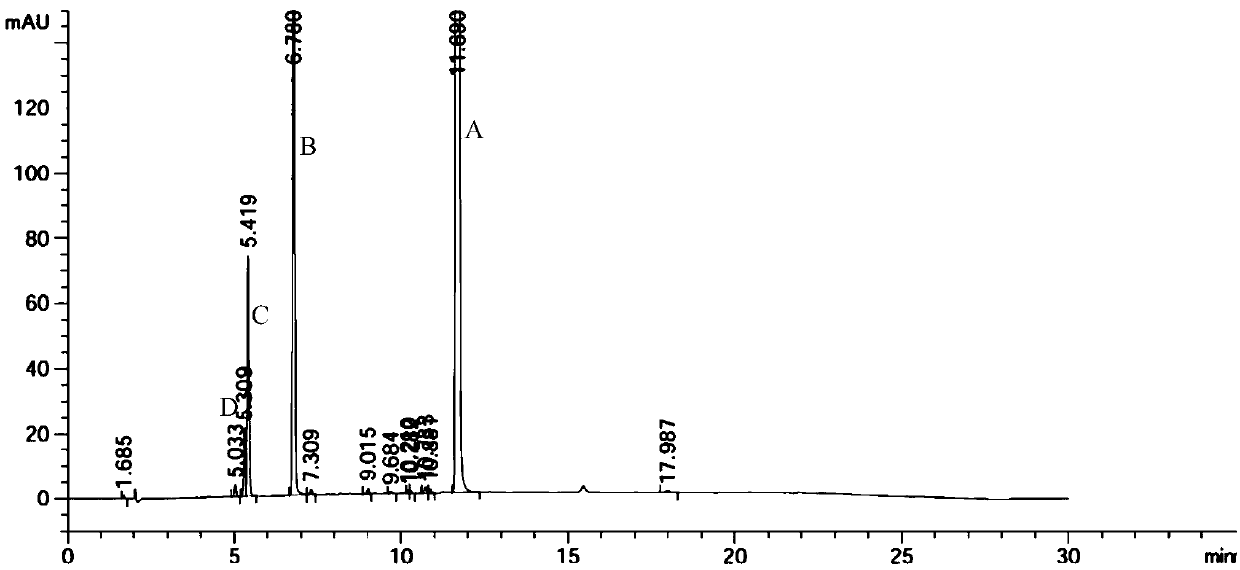

[0051] Example 3: Synthesis of 3-n-butyl-1 (3H)-isobenzofuranone (addition of CuI)

[0052] O-formylbenzoic acid (5.00 g, 33.3 mmol) was dissolved in tetrahydrofuran (25.0 mL) to obtain a tetrahydrofuran solution of o-formylbenzoic acid. Add 2mol / L tetrahydrofuran solution of n-butylmagnesium bromide (36.6ml, 73.3mmol) and 0.65g CuI into a 250mL three-necked flask. After cooling down to 0°C, add the tetrahydrofuran solution of o-formylbenzoic acid dropwise into the tetrahydrofuran solution of n-butylmagnesium bromide, and control the internal temperature at 0-25°C. After dropping, the reaction was continued at 25° C. until the end of the reaction monitored by HPLC. Adjust the pH to 1-2 with 3 mol / L hydrochloric acid, separate the layers, extract the aqueous layer with isopropyl acetate (50 mL×2), combine the organic phases, and wash with saturated brine (100 mL). After the organic phase was concentrated, 6.25 g of 3-n-butyl-l(3H)-isobenzofuranone was obtained. The HPLC puri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com