Cyclohexane oxidation byproduct treatment method

A treatment method and technology of cyclohexane, which is applied in the field of treatment of cyclohexane oxidation by-products, can solve problems such as insufficient utilization of cyclohexane oxidation by-products, and achieve the effects of avoiding crystallization, fully utilizing and reducing, and avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

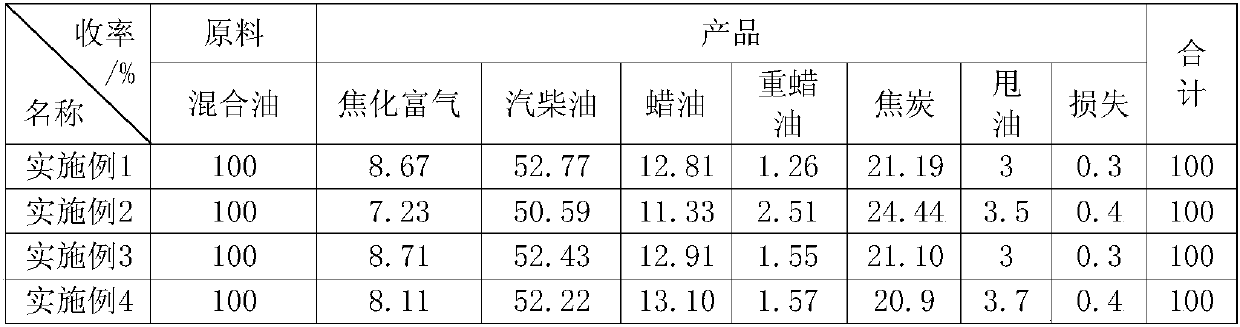

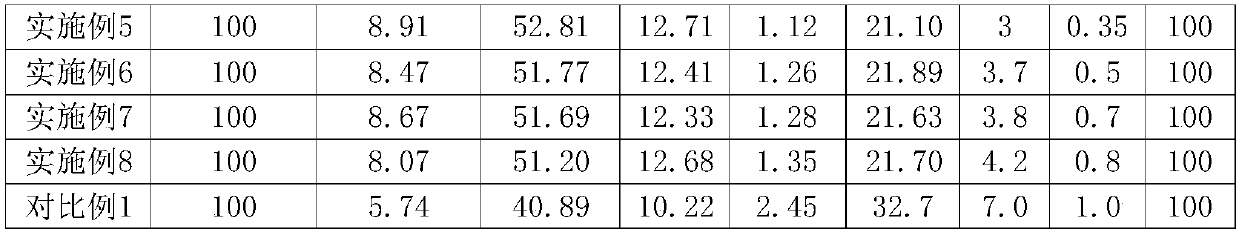

Examples

Embodiment 1

[0033] Put 100L of by-products from the process of cyclohexane oxidation to cyclohexanone and cyclohexanol (main components are ketones, ethers, alcohols and acidic organics) in the process of non-catalytic oxidation of cyclohexane into a 300L reactor and add it through a feed pump After 30L of sodium hydroxide solution with a concentration of 20wt% (the weight of sodium hydroxide accounts for 5.8% of the by-product of cyclohexane oxidation), control the temperature to 70℃, stir for 2h, after the reaction is completed, stand for 2h to separate , Removal of gas phase products by rectification at 0.1Mpa and 110°C to obtain by-products separated by alkaline washing. Then, the by-products and vacuum residue obtained after alkaline washing separation were mixed in a ratio of 1:50 and then added to the delayed coking reactor. The temperature in the heating furnace was controlled to 495°C, the reaction pressure was 0.2MPa, and the oil phase The mixture of vacuum residue and vacuum res...

Embodiment 2

[0035] The difference from Example 1 is that the ratio of the oil phase to the vacuum residue is 1:10.

Embodiment 3

[0037] The difference from Example 1 is that the ratio of the oil phase to the vacuum residue is 1:100.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com