Replacement flow shop energy efficiency optimization scheduling method integrating delivery date configuration

A technology that integrates delivery dates and optimizes scheduling. It is applied in design optimization/simulation, energy industry, genetic rules, etc., and can solve problems such as corporate credit analysis, violation of the delivery date agreement between the manufacturer and the customer, and production efficiency decline.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

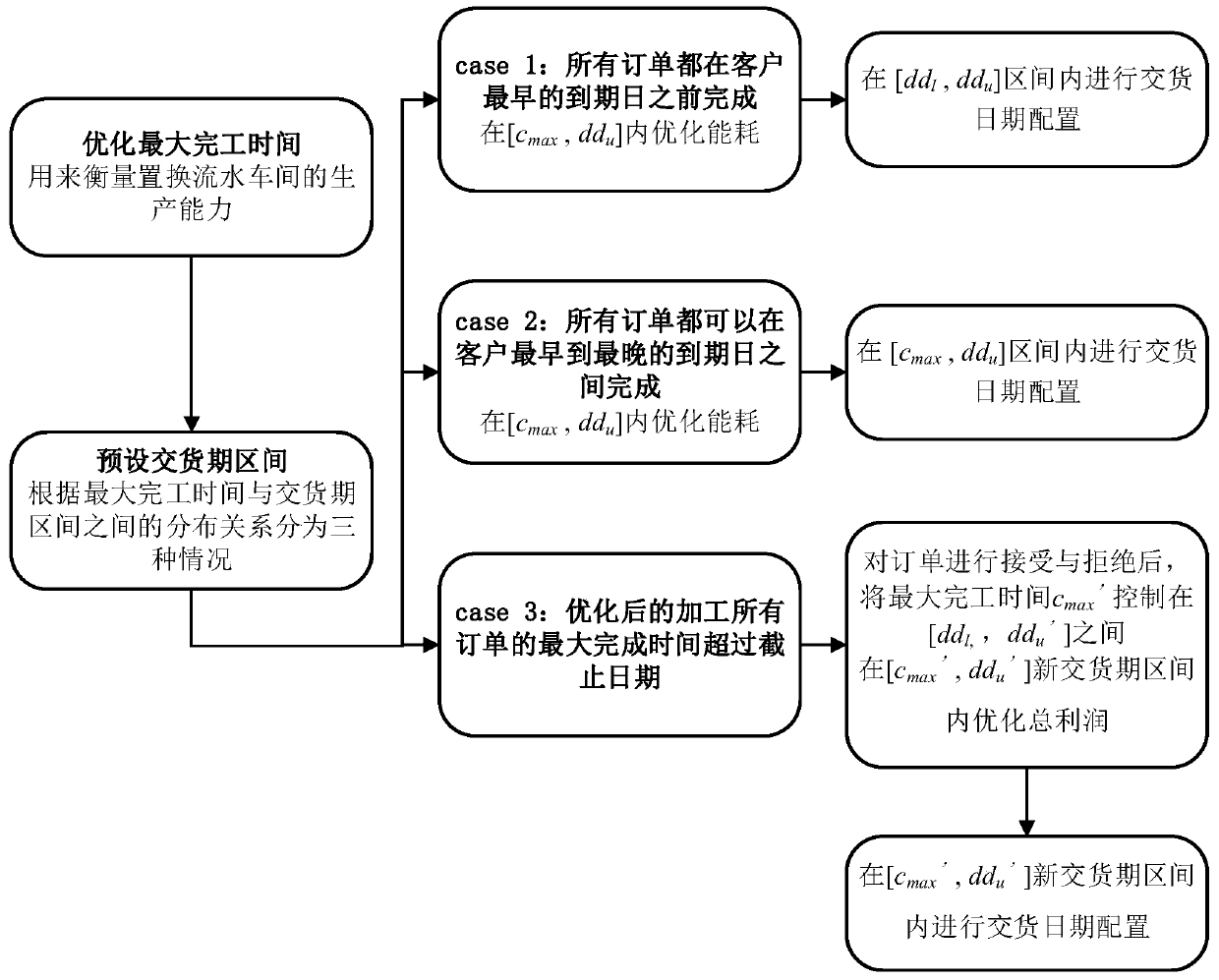

[0103] The present invention provides an energy efficiency optimization dispatching method for a replacement flow shop that integrates delivery date configuration, collects production data, and establishes a mathematical programming model; generates three frameworks for energy efficiency optimization and delivery date configuration; the first two frameworks combine workpieces and machines In the third framework, the code of rejecting the order is spliced after the code of receiving the order; according to the coding method, the NEH heuristic algorithm is used to generate the initial solution and initialize the tabu table; perform a tabu search on the initial solution generated later, and update Local optimal solution and taboo table; judge whether the termination condition is satisfied, and if so, enter the next step, otherwise proceed to the next iteration; decode the obtained optimal solution to obtain the scheduling plan; generate the initial population according to the enc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com