An energy efficiency optimization scheduling method for replacement flow workshop with integrated delivery time configuration

A technology that integrates delivery time and optimal scheduling, applied in design optimization/simulation, genetic law, energy industry and other directions, can solve problems such as increased energy consumption, increased energy consumption cost, analysis, etc., to achieve less machine time and space, optimize Energy consumption level, the effect of improving algorithm efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

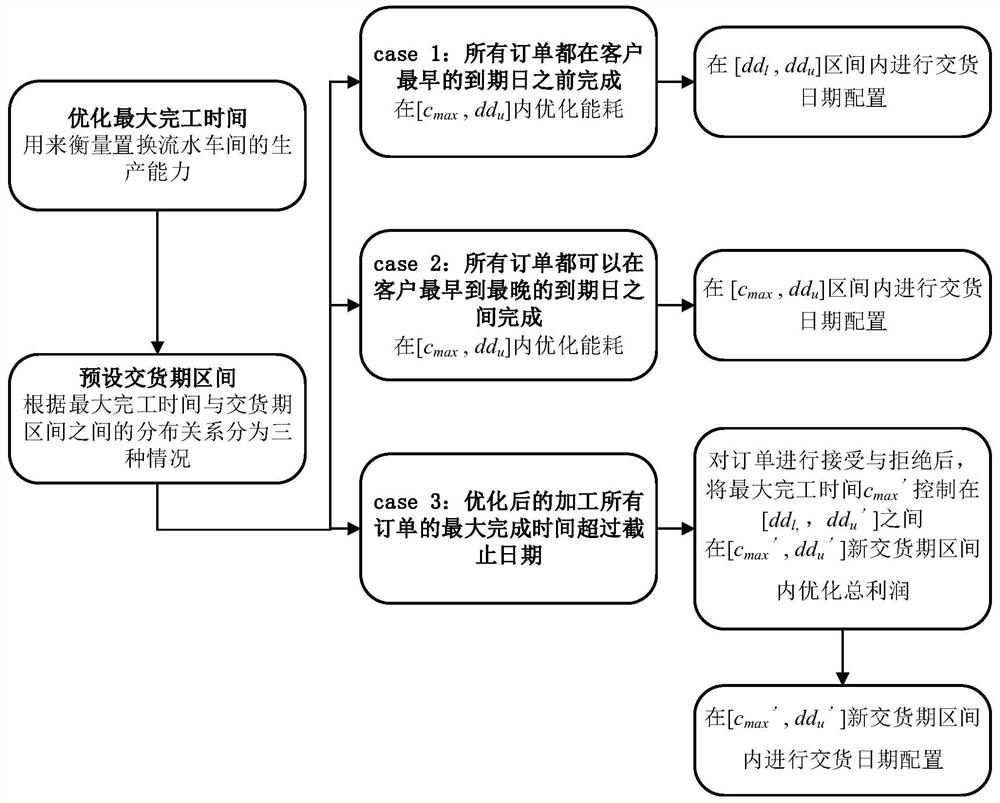

[0103] The invention provides an energy-efficiency optimization scheduling method for a replacement flow shop with integrated delivery schedule configuration, which collects production data and establishes a mathematical programming model; generates three frameworks for energy efficiency optimization and delivery schedule configuration; the first two frameworks combine workpieces and machines Integrate coding between them; in the third framework, the coding of rejecting orders is spliced after the coding of receiving orders; the NEH heuristic algorithm is used to generate the initial solution according to the coding method, and the tabu table is initialized; Local optimal solution and taboo table; judge whether the termination condition is met, if so, go to the next step, otherwise, go to the next iteration; decode the obtained optimal solution to obtain the scheduling plan; generate the initial population according to the coding method; Calculate the target fitness value and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com